Swiss Type CNC Lathe

SW-06

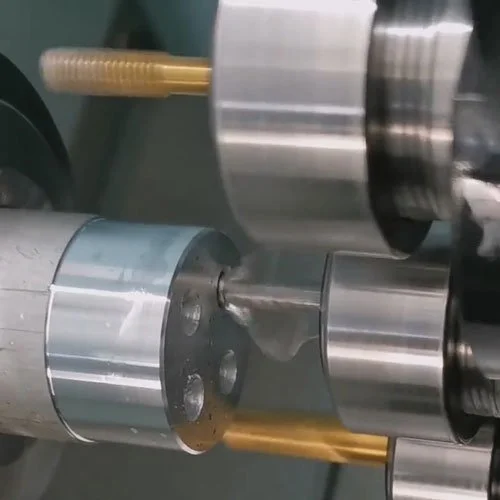

The SL-X is a CNC turning and milling machine that provides various possibilities of tooling combinations with a more powerful spindle (7.4 HP). It is the best solution to satisfy the diverse demand for metalworking and the goal to minimize the tool change time.

STANDARD CONFIGURATION

Core Features for High-precision CNC Turning.

10

Technical Specifications |

SW-06 |

|---|---|

Spindle Bore |

Φ6mm(0.236") |

Max. Machining Length |

150mm(5.9") |

Max. Axial Drilling Diameter |

4mm |

Spindle Speed |

8000RPM |

Max. Turning Dia. (L<50mm/1.97 in) |

Φ200mm(7.87 in) |

Spindle Center to Slat Table |

Φ50mm(1.97 in) |

Spindle Bore |

Φ55mm(2.17 in) |

Max. Bar Material Dia. |

Φ45mm(1.77 in) |

Spindle Nose |

A2-5 |

Spindle Motor Power |

7.5kw |

Spindle Max. Speed |

3500rpm |

Servo Turret |

Standard |

Single-hole Drill Tool Holder |

Φ25(3pcs) |

Single-station turning Tool Holder |

20*20 |

Double-station turning Tool Holder |

/ |

X Axis Servo Motor Power |

1.3kw |

Z Axis Servo Motor Power |

1.3kw |

Y Axis Servo Motor Power |

1.8kw |

X Axis Travel |

1000mm(39.37 in) |

Z Axis Travel |

300mm(11.81 in) |

Y Axis Travel |

220mm(8.66 in) |

X/Z Axis Rapid Feed Speed |

20m/min |

Y Axis Rapid Feed Speed |

15m/min |

Positioning Accuracy |

±0.01 |

Repeat Positioning Accuracy |

±0.01 |

Spindle Rotate Runout Tolerance |

±0.01 |

Live Tool |

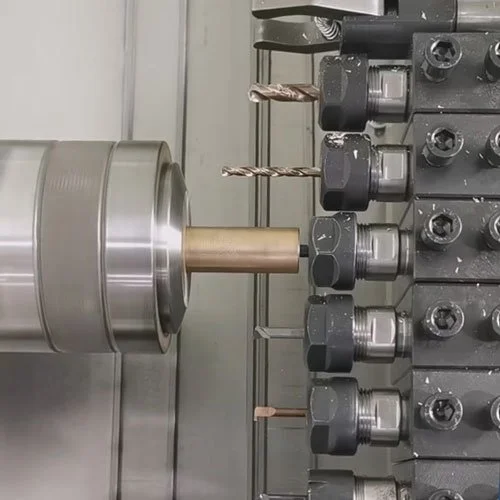

4*ER25-Radial 4*ER25-Axial |

Live Tools Power |

2.6kw |

Live Tools Max. Speed |

3000rpm |

Live Tools Max. Drilling Dia. |

Φ10mm |

Live Tools Max. Tap Dia. |

M8 |

Max Tool Install Capacity |

16 |

Weight |

3T |

Dimensions(LxWxH) |

2130*1600*1970mm 83.86*62.99*77.56 in |

CONFIGURATION |

SL-X YM |

||

|---|---|---|---|

Standard |

8TA/22TB |

||

X/Y/Z Servo Drive and Motor |

|||

Taiwan Linear Guideway, Ball Screw |

|||

Hydraulic Station |

|||

Spindle Braking Device |

|||

Rotary Hydraulic Cylinder |

|||

Lubricating System |

|||

3-color Tower Light |

|||

LED Working Light |

|||

Cutting Fluid Tank |

|||

Toolbox |

|||

Optional |

Transformer |

||

Chip Conveyor |

|||

Oil Mist Collector |

|||

3-Jaw Chuck |

|||

Oil-bath Bar Feeder/Auto Bar Feeder |

|||

Truss Manipulator/Articulated Robot |

|||

Parts Catcher + Workpiece Belt Conveyor |

|||

GSK/SYNTEC CNC SYSTEM |

|||

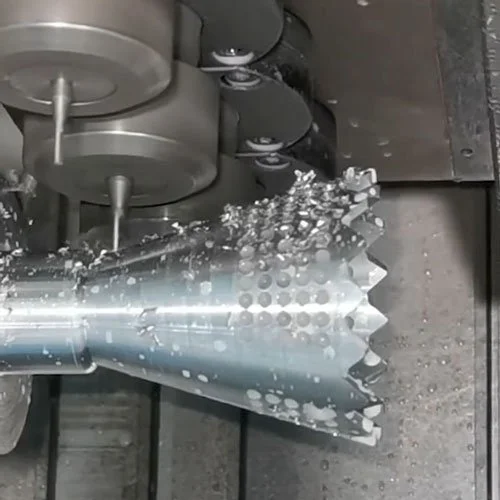

Application

Competent to handle the turning process with brass, bronze, aluminum, steel, stainless steel, and rigid plastic with bars diameter up to Φ46 mm or single workpieces up to Φ50mm.