Choice of Automatic Bar Feeder for CNC Lathes, Oil Bath Bar Feeder, or Servo Bar Feeder?

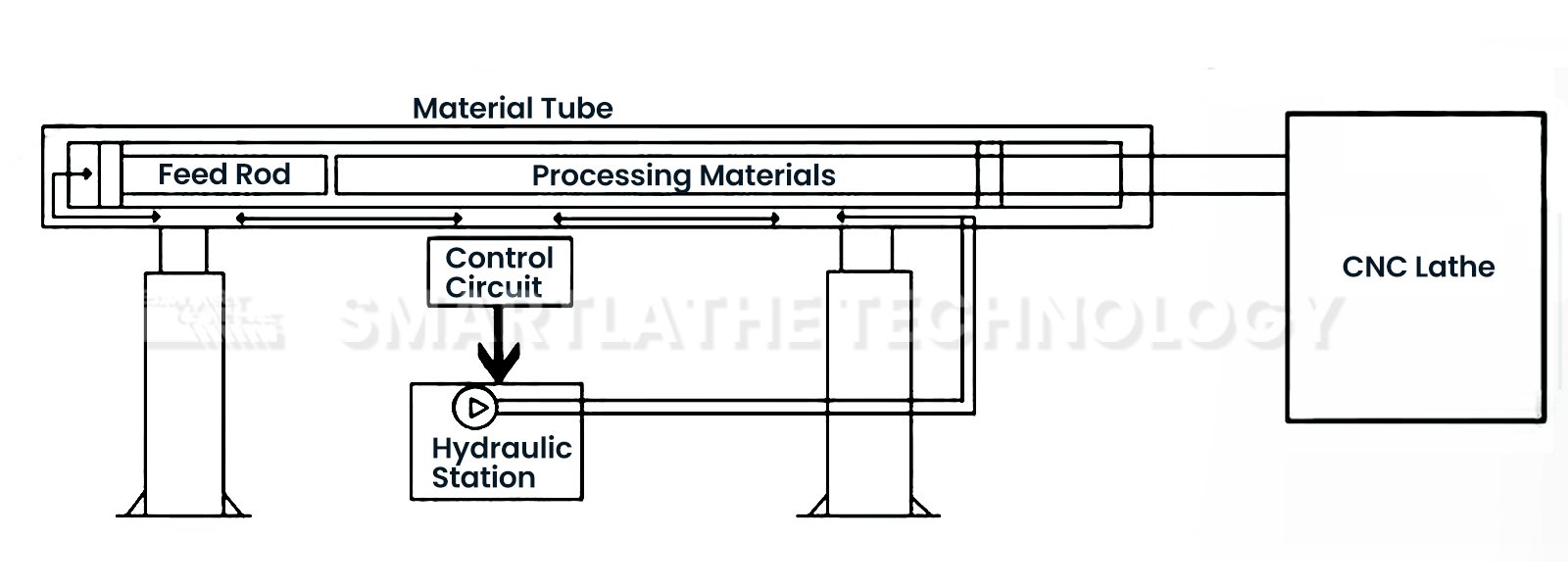

CNC lathe automatic feeder refers to a feeding machine that cooperates with a CNC lathe that can continuously process materials to achieve automatic feeding, thereby improving the processing efficiency and automation of the equipment.

Oil bath bar feeder and servo bar feeder are common automatic feeding equipment, and they have different working principles and features.

Oil Bath Bar Feeder

The oil bath bar feeder soaks the material in lubricating oil to form an oil film on its surface, thereby reducing friction and wear when the steel is in contact with the machine. This type of feeder is suitable for some traditional mechanical equipment and is usually used to handle larger diameter materials.

Servo Bar Feeder

In comparison, servo bar feeder has attracted the attention of many users with its advantages such as high precision, strong adaptability, and low maintenance costs. Equipped with advanced oil film lubrication system and servo control technology, the oil film feeder can achieve more precise and stable feeding, satisfying scenarios that require high processing accuracy. Although the servo bar feeder has a relatively high cost and high equipment requirements, its significant advantages in improving processing efficiency and product quality make it the first choice for many companies.

Differences between oil bath bar feeders and servo bar feeders:

|

Feature |

Oil Bath Bar Feeder |

Servo Bar Feeder |

|

Working Principle |

Material immersed in lubricating oil to form oil film |

Thin oil film formed on material surface through lubrication system |

|

Precision and Stability |

Lower precision, not suitable for high-precision machining |

Provides high precision and stability, versatile |

|

Cost and Budget |

Lower cost, suitable for limited budgets |

Higher cost, but longer lifespan and lower maintenance costs |

|

Maintenance Requirements |

Requires frequent lubricating oil changes, higher maintenance costs |

Lower maintenance costs, longer lifespan |

|

Application Scenarios |

Suitable for some heavy load scenarios, such as low-demand machining |

Suitable for scenarios requiring high-precision machining and high stability |

In summary, when selecting automatic bar feeding equipment, you should comprehensively consider factors such as your own processing needs, budget, and equipment performance. Whether it is an oil bath feeder or an oil film feeder, it will provide reliable technical support for workshop production and achieve more efficient and precise processing technology.

If you have any questions about our CNC lathe optional bar feeders, please don't hesitate to reach out to us. We Smartlathe team of professional technicians is dedicated to providing you with exceptional service and support.