POWER TURRET CNC LATHE

ST-Series

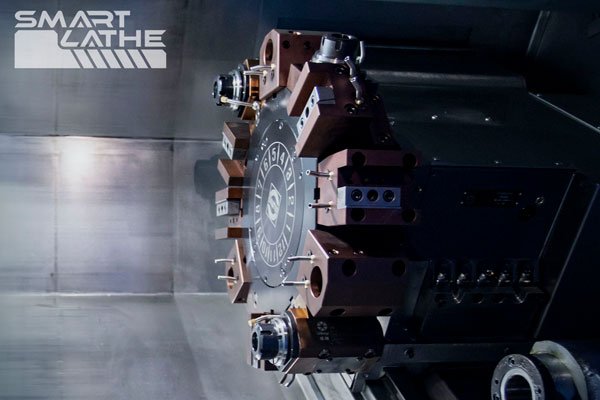

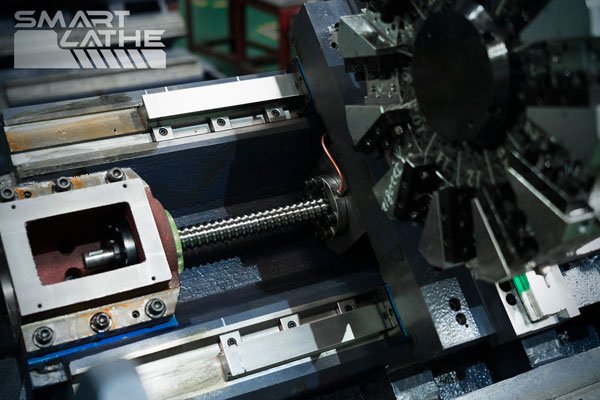

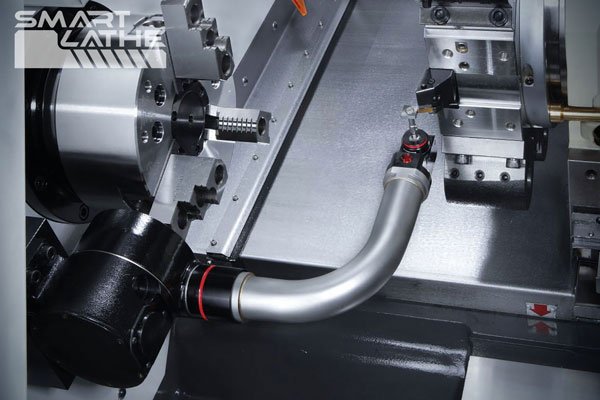

ST Series is an integrated multiplex turning center that combines the processing capabilities of a turning center with those of a machining center via Y and C axis control. The versatile 12-station power turret allows it to completely manufacture parts with complex shapes in a single setup operation.

The launch of the ST Series is the pursuit of the maximum potential of flexibility, accuracy, reliability, and productivity.

| Techical Data | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Features | ||||||

|

||||||

| Optional | ||||||

Auto Bar Feeder

Auto Tools Setter

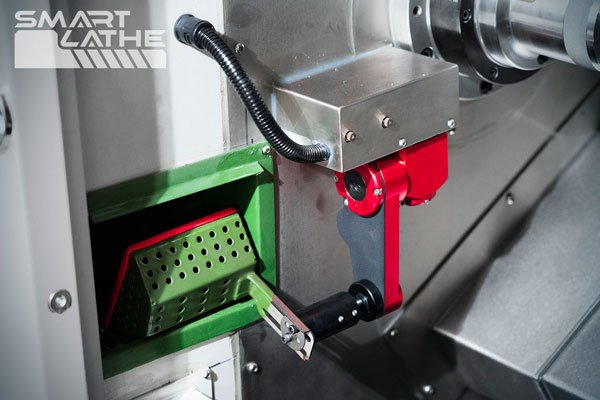

Part Catcher

Oil Mist Collector

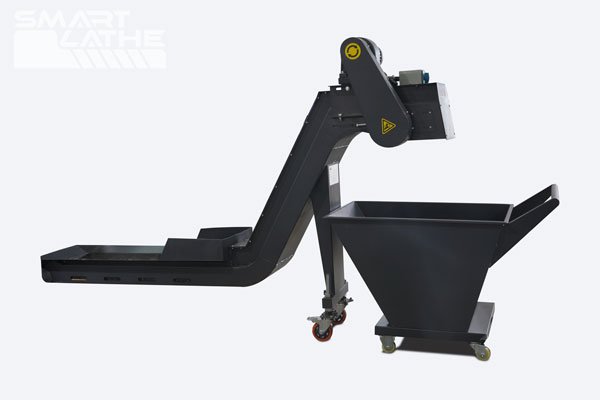

Chain Chip Conveyor

Fanuc CNC System |

||||||

Application

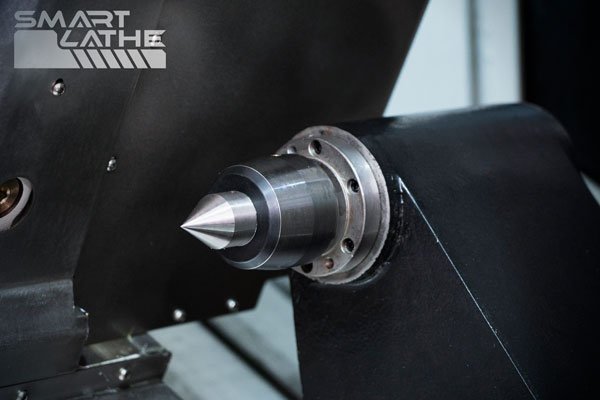

Competent to handle the turning process with brass, bronze, aluminum, steel, stainless steel, and rigid plastic with bars diameter up to Φ51 mm or single workpieces up to Φ300mm. High Rigidity casting iron body provides the possibility of higher hardness materials and better smoothness (smaller roughness). ST-52YT is equipped with a CNC program-controlled hydraulic tailstock, a 12-station power turret, a power milling head that can be installed at the upper or bottom position of the Y-axis (turret), high rigidity cutting, suitable for long-axis turning, milling, Processing of complex multi-process products such as drilling and tapping.

Case Study

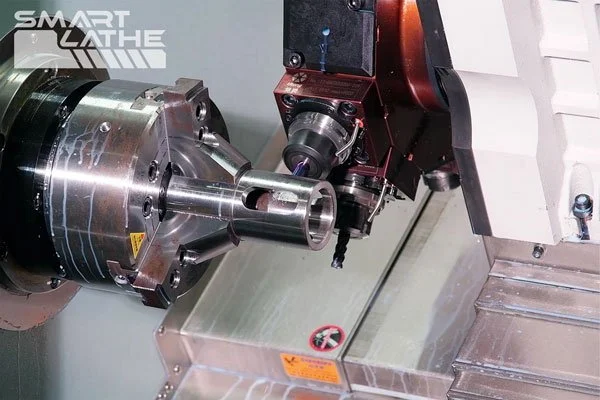

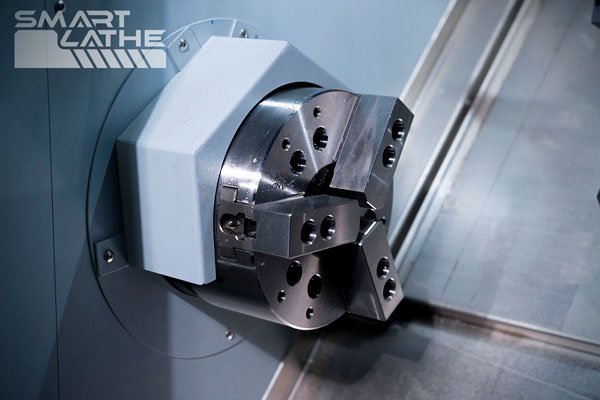

Configuration: ST-52YT installs the 3-Jaw Hydraulic Chuck, Power turret.

Workpiece: Connection shaft, 45 steel.

Machining Process: Turning, Facing, Drilling, Milling.

Turning Duration: within 380 seconds of one-time processing