Optimizing CNC Lathe Machining Processes with Fusion 360 Post-processing

CNC lathes are indispensable in modern manufacturing, and Fusion 360's post-processing capabilities offer new avenues for efficiency and innovation in the machining process. Whether you operate a small workshop or a large-scale manufacturing facility, using Fusion 360 to handle CNC lathe stuff can help you get awesome results.

1. Streamlining Programming with Intelligence

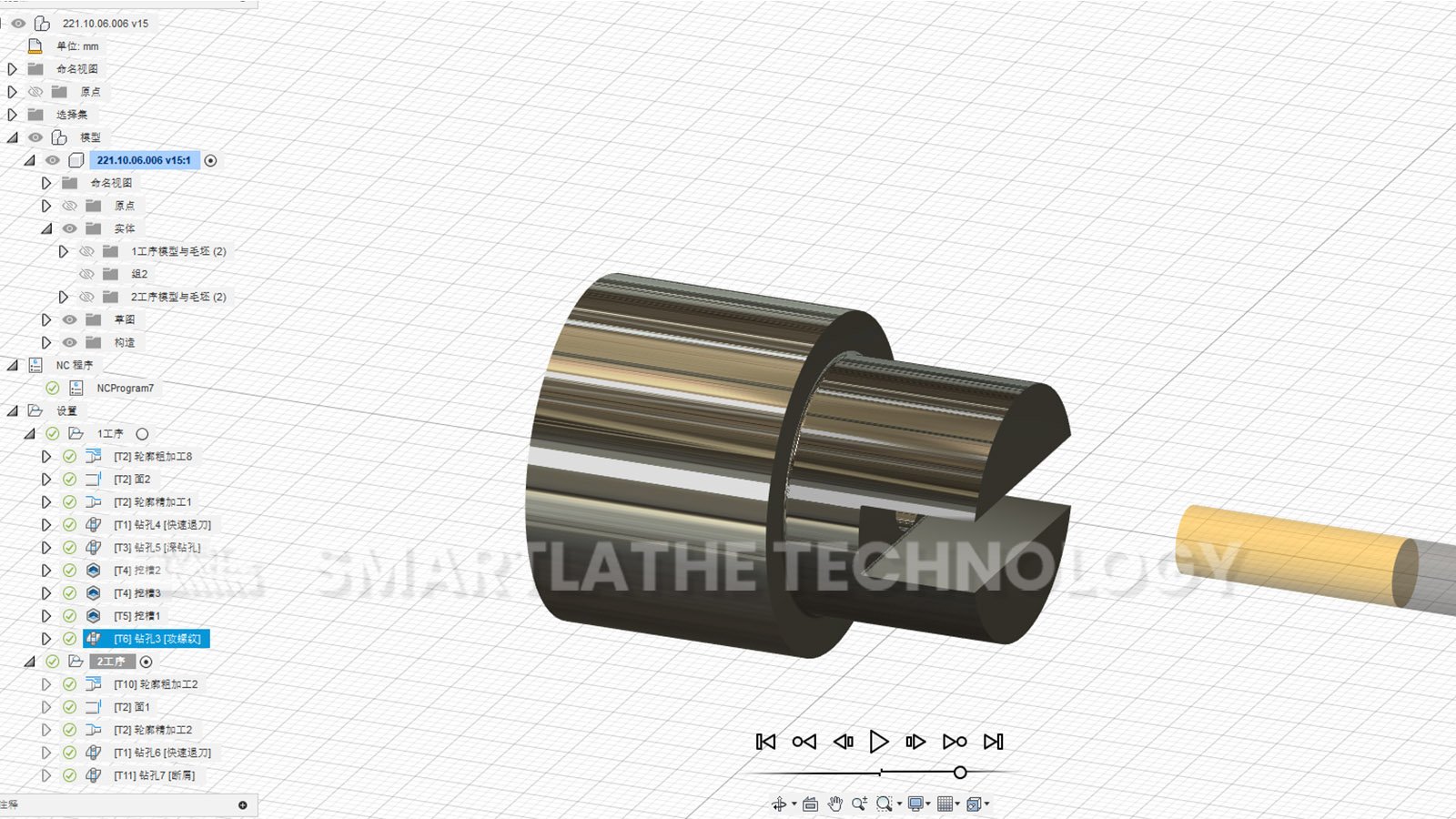

Fusion 360's post-processing functionality provides an intelligent platform for CNC lathe programming, streamlining the process from design to manufacturing. Users can effortlessly convert design data into CNC lathe-readable code, eliminating the need for laborious manual programming. Whether you're new to CNC machining or an experienced operator, Fusion 360 offers intuitive programming solutions to accelerate your workflow and enhance production efficiency.

2. Ensuring Precision for Quality Assurance

Precision is paramount in digital manufacturing, and Fusion 360's post-processing capabilities are tailored to meet this demand. Users can fine-tune and control parameters for CNC lathes with precision, ensuring meticulous attention to detail throughout the manufacturing process. Whether you're machining intricate components or high-precision parts, Fusion 360 delivers optimal manufacturing solutions to maximize product quality and machining accuracy.

3. Enhancing Efficiency for Competitive Advantage

In today's competitive landscape, efficiency and quality are the cornerstones of manufacturing excellence. Fusion 360's post-processing functionality empowers users to optimize the manufacturing process and boost production efficiency through intelligent algorithms and tools. Whether you're producing single components or running batch production, Fusion 360 generates optimized machining paths to maximize efficiency and control costs.

In conclusion, Fusion 360's post-processing capabilities offer unparalleled customization and intelligent processing, enabling seamless generation of CNC lathe-compatible code and optimizing machining paths to improve efficiency and quality.

With our team of experienced engineers, Smartlathe provides tailored solutions to address your specific needs, whether it's machining complex parts, working with specialized materials, or achieving high precision. Partner with us to leverage Fusion 360's capabilities and propel your manufacturing operations to new heights. Let's collaborate to make your projects a success!