The Significance of CAM Post Processors and the Most Popular Post Processors

Machine design and control are accomplished using CAD and CAM technologies. Machines require post-processors to make sure the code that is provided to them is readable and understandable and to maximize machine performance.

Computer-Aided Design, or CAD, the process of designing itself is made simpler. Computer-aided manufacturing, or CAM, on the other hand, makes production programming easier. CAD and CAM were initially used independently, but as time went on, using them in tandem became much simpler and more effective, making it easier for CNC programmers to program machines.

What exactly is a post-processor?

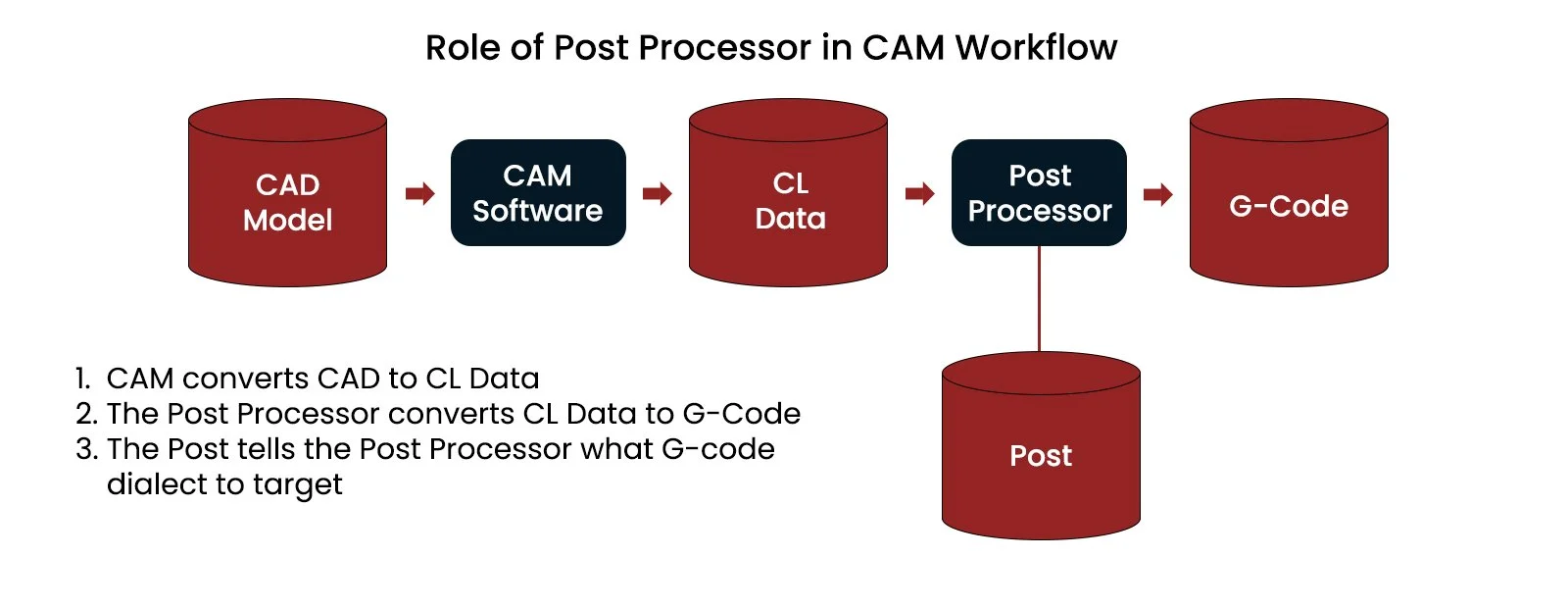

A CNC machine must comprehend its commands to carry out the specific task for which it is designed. The post-processor converts CAM data into commands (G-code) that a CNC machine can comprehend.

CL-Data is the output data produced by any CAM system you choose to utilize. In actuality, CL-Data specifies the route a machine tool takes when processing a specific part. However, since the CNC machine does not know this path right away, a post-processor is required to convert CL-Data into G-code, which the CNC machine can use. The postprocessor, which is the language used to control and manage CNC machines, essentially acts as a "bridge the gap" between the CAM system and the CNC machine (G-code).

Why do we need a post-processor?

Accuracy, machining quality, and optimal use of your CNC machine depend on the postprocessor you use. Without a post-processor or a poor-quality post-processor, you can end up wasting a lot of time, damaging parts, ruining machines, and most dangerously, injuring workers.

With post processors, you can realize significant savings and increase productivity. Delivers excellent results in pattern making, specific drilling patterns, pattern adjustments, right angle milling, tool life tracking, G-code documentation to further clarify operator data, setting variable options, and more. The CAM post processor enables the production process to start and continue without errors.

Creating a post-processor is a delicate process that requires knowledge and experience. It is a very important part of CNC programming. The fact is that you can have the best design and the best CAM system for CNC programming, but without exactly the right code to communicate with the machine, you don't have a complete process, and there is a lot of damage and low productivity. risk.

To put it simply, the essence of a good postprocessor is to generate a G-code that enables high-quality and safe processing while optimizing processing time, tooling, and machine resources.

The Most Popular Post Processors

Currently, the most popular post processors are Fusion360 and MasterCAM. The following table is a brief introduction to the two post-processors.

|

Post Processor |

Fusion 360 |

MasterCAM |

|

Description |

Fusion 360 is a professional 3D CAD Design software owned by Autodesk. They provide a free version for personal user and business owners. It combines on one platform CAM, CAE, and CAD. |

MasterCAM is a good choice for beginners and experts alike; one of its best features is its simple learning curve and user interface. It was developed by CNC Software Inc. CNC programming and sophisticated modeling are two of MasterCAM's most well-liked features. |

|

Features |

|

|

Smartlathe CNC lathe equipment system SMARTBRAIN supports MasterCAM post-processor and Fusion 360 post-processor. With these, experienced professionals can handle complex machining tasks with ease and precision according to the actual needs.