What is CNC Lathe?

CNC lathe is a computer-numeric controlled machine tool specialized in CNC turning machining, including taper turning, hard turning, spherical generation, facing, cutting off, knurling, drilling, grooving, etc. Compared to a conventional lathe, CNC lathes are operated with precise design instructions and programs to improve the productivity and precision of CNC machining demands.

Benefits from CNC lathes.

- Greater capacity

- Higher precision

- Safer operation

- Shorter turnaround time

Types of CNC Lathes

CNC Lathes – How Many Axis?

CNC lathes are diversified in accordance with the machining demands and are normally classified by how many axes they have. The various axes determine how the workpieces can be positioned, rotated, and handled during the machining process.

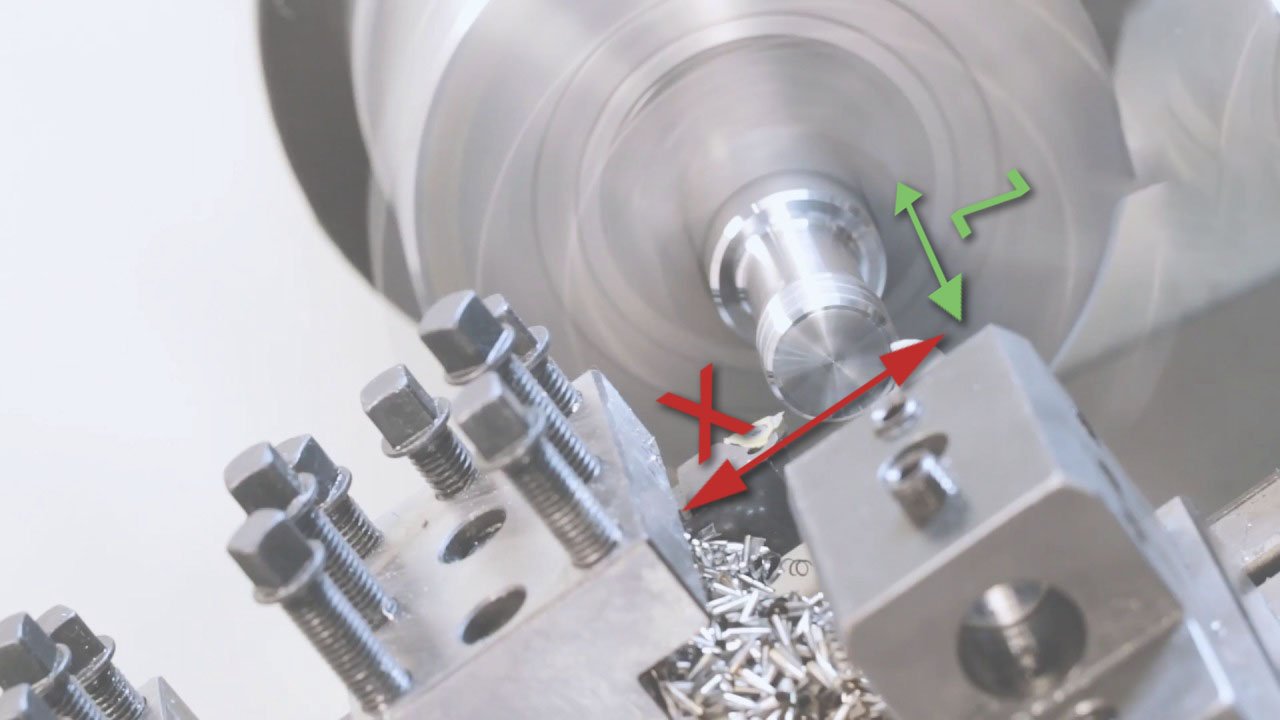

2-Axis CNC Lathe

This CNC lathe is the most basic type, containing two linear axes, X and Z axes. It can be used for OD and ID machining of workpieces, face machining, or drilling and tapping in the center of the part. But milling is not workable.

3-Axis CNC Lathe

With a 3-axis CNC lathe, a C axis and life tool system are added, allowing the part to be positioned so that standard milling operations, boring, and tapping operations can be performed. Helical milling operations that require the slow sync rotation of the workpiece are possible.

The 3-axis CNC lathe adds a C-axis and side milling tools based on the 2-axis CNC lathe, allowing the precision positioning of parts so that high-quality milling, boring, and tapping operations can be performed. The spiral milling operation can be achieved by slow synchronous rotation of the workpiece in the C-axis.

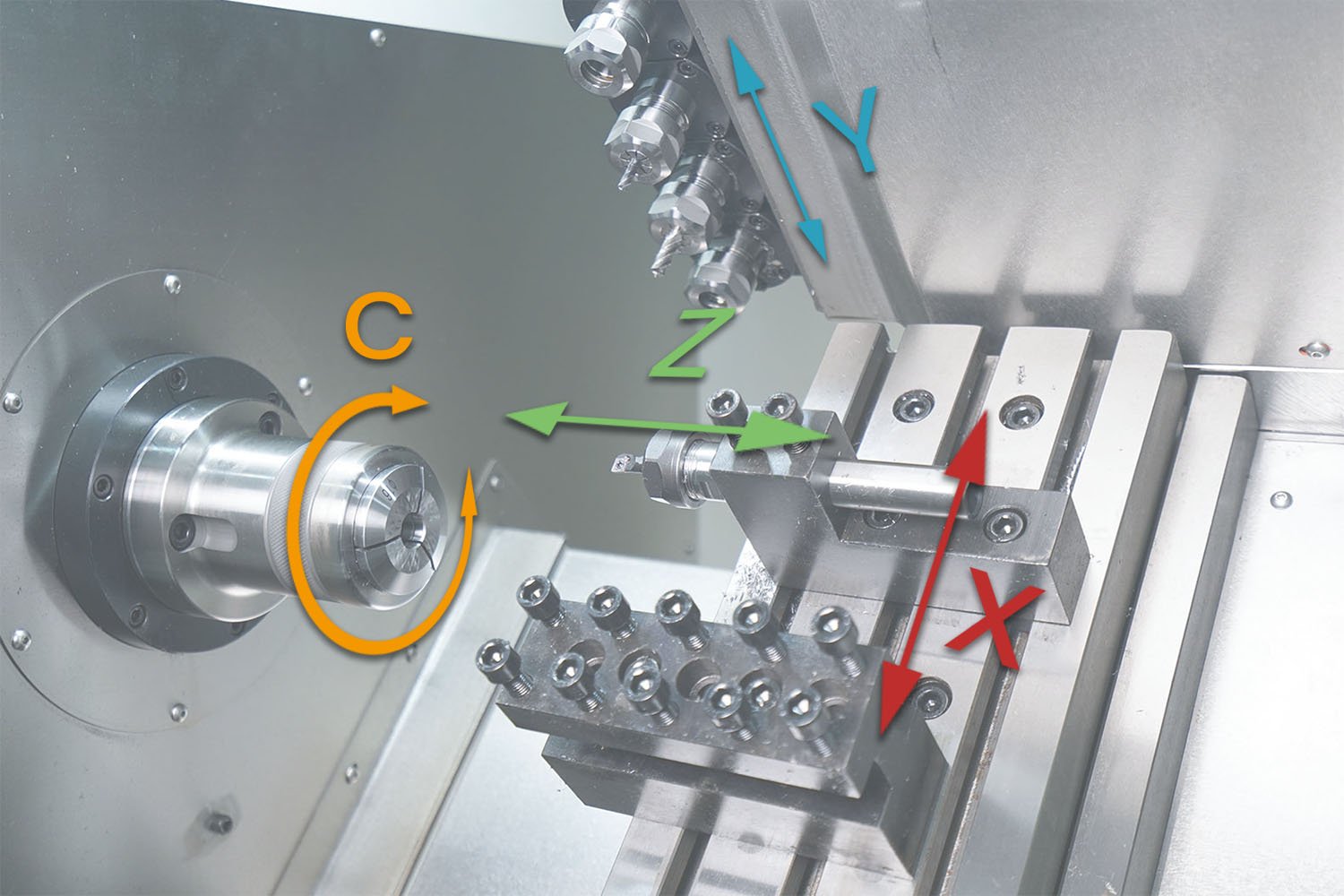

4-Axis CNC Lathe

The 4-axis CNC lathe equips a Y-axis, which benefits the off-center machining operation. Four-axis lathe is more powerful and a good choice for irregular and complex lathe work.

5-Axis CNC Lathe

A 5-axis lathe is actually a 3-axis CNC lathe equipped with an additional turret. Thus, a 5-axis lathe machine will have two axes on each of the upper and lower turrets, with a C-axis on the rotary spindle. This would allow two tools to be employed on the workpiece at the same time, the machining speed will be dramatically booming.

6 or More Axis CNC Lathe

More axes are equipped to improve flexibility and productivity, Obviously, the higher cost of the machine will be.

Also, the CNC lathe could be classified by the machining requirements.

1) High-speed lathe: simple design, consisting of headstock, tailstock, and tool holder, providing three or four-speed options.

2) Engine lathe: The most common lathe that can handle a wide range of metals in a long size at various speeds.

3)Turret lathe: multi-functional thanks to the turret design with tool holders can be installed.

4) Toolroom lathe: Entry-level option for the startup and small shops.

According to the position of the lathe spindle, the CNC lathe could be classified as below.

1) Vertical CNC lathe: the lathe spindle is perpendicular to the horizontal plane, and the workpiece is clamped with a large diameter round table

2)Horizontal CNC lathe: can be divided into flatbed CNC lathe and slant bed CNC, the structure of slant bed type makes the lathe more rigid and easier for chip removal.