Helio’s Experience with the Versatile SmartLathe SL X

Navigating Brazil’s Strict Safety Standards for Precision Turn-Mill Projects

From first seeing the machine in action to bringing it into his own workshop, Helio’s journey with SmartLathe is a story of craftsmanship, customization, and commitment.

Meet Helio

Helio is an award-winning engineer and multi-talented craftsman from Brazil. Known for his precision work and creativity, he produces high-quality parts for a variety of industries. His reputation was built on a combination of skill, innovation, and a passion for working with the best tools available.

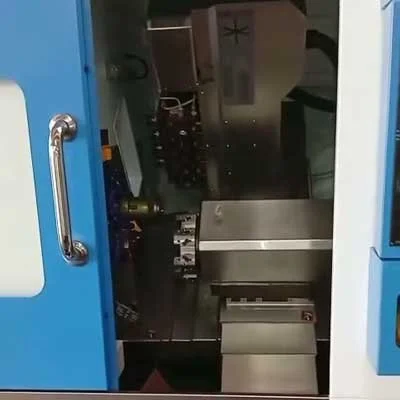

Helio first discovered the SmartLathe SL-X while visiting a friend’s workshop. The machine’s compact yet versatile turn-mill configuration immediately caught his eye:

4+4 live tooling head with Y-axis

8-station servo turret

Comprehensive multi-function machining in a space-saving design

Not content with just watching, Helio stepped up to operate the SL-X himself—and was impressed by its smooth performance, flexibility, and robust build.

From Curiosity to Commitment

Eager to own this powerful machine, Helio reached out to SmartLathe directly. Since he had already tested the machine, the configuration and pricing were quickly finalized.

Importing a CNC machine into Brazil is no small feat—customs clearance, multiple fees, and strict compliance requirements can all slow the process. During conversations, Helio shared a key insight: Brazil enforces the NR 12 industrial machinery safety standard, which requires specific safety switch systems.

SmartLathe responded by offering a customized SL-X fully compliant with NR 12, ensuring both safety and regulatory approval. With these details confirmed, Helio placed his order, and production began immediately.

A Special Project: Recreating a Trophy

Helio’s craftsmanship extends beyond engineering—he has won prestigious Olympic-style awards in his field. During our discussions, he shared a personal goal: he wanted to reproduce his award trophy using the SL-X.

Our engineering team prepared a sample machining project using Helio’s own SL-X at our factory. The finished trophy not only served as a special demonstration but also doubled as the final acceptance test before delivery.

The result exceeded expectations, and Helio’s confidence in his new machine was solidified.

Delivery and Anticipation

After the successful pre-delivery test, we carefully cleaned, packed, and shipped the SL-X to Brazil. Helio is now preparing his workshop for its arrival and has promised to film an unboxing and startup video.

Meanwhile, the SmartLathe team is ready to provide remote technical support to ensure a smooth start to production.

The SmartLathe Experience

Helio’s story highlights what sets SmartLathe apart:

Hands-on experience before purchase

Seamless ordering and delivery process

Customized compliance solutions for local regulations

Pre-delivery testing for total confidence

Reliable after-sales support across continents

From first inspiration to successful creation, SmartLathe helps customers turn ideas into reality.

Thinking about upgrading your workshop like Helio?

If you’re facing similar challenges—whether it’s mastering complex turn-mill projects, navigating local safety regulations, or needing a reliable partner for customized CNC solutions—we’re here to help.

Contact us to discuss how SmartLathe can support your unique needs and take your machining capabilities to the next level.