A Comprehensive Chronicle of the ST-46YTC CNC Lathe Project – From Client Vision to Shipment Perfection

Client’s requirement: The client provides detailed requirements for the workpiece and machine.

1. Workpiece drawing.

2. Automatic requirement.

Material feed in, finished part feed out.

Handling of oil mist.

3. Extend the range for machining different workpieces.

The long workpiece, the workpiece with angled holes, high accuracy, etc.

Evaluation and suggestion from Smartlathe.

After evaluation, we offer a detailed solution to the client.

CNC model: ST-46YTC

With below configuration so that to fully match client’s requirement.

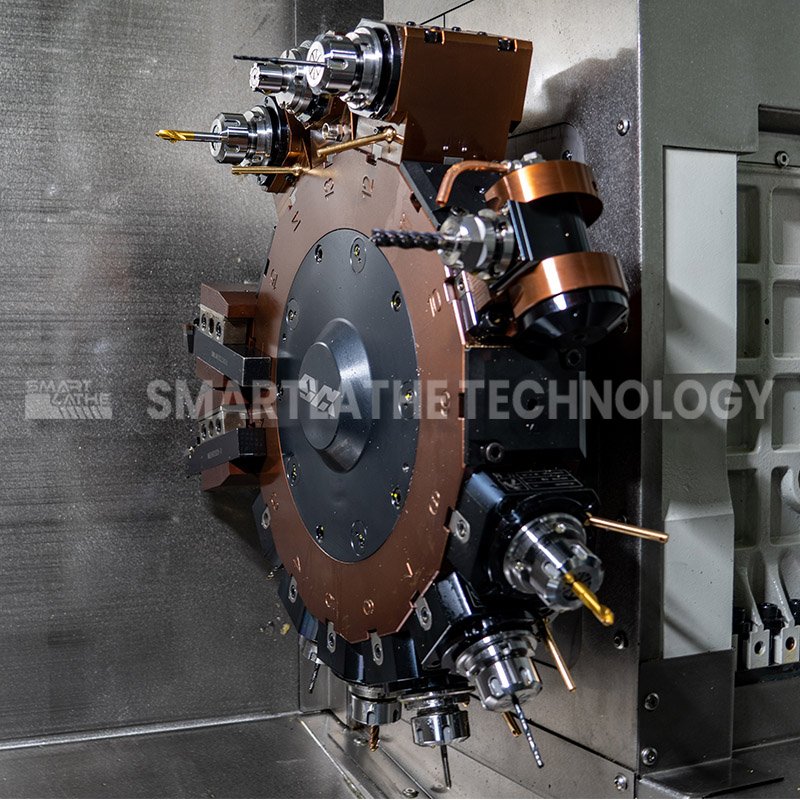

15 Stations Power Turret

with Y-axis

Tailstock

Oil Mist Collector

Chain Chip Conveyor

Angle Adjustable

Living Tool

Part Catcher

Oil Skimmer

High Speed (Max. 8000rpm)

Living Tool

Fanuc System

Servo Bar Feeder

Sample Demo: After completing the machine, we proceed with a sample demo based on the client’s drawing.

1. Sample Processing

Run the machine and process the sample

Take video recordings of the whole machining process

2. Sample Review

Dimensions and appearance

Client Review & Acceptance.

The client reviews the images, videos, and sample demo results, and then provides confirmation.

Packing of Machine & Exiting Factory

1. The machine to be packed into the wooden box. We design the best packing layout so that to be safe for transportation and to be space-saving.

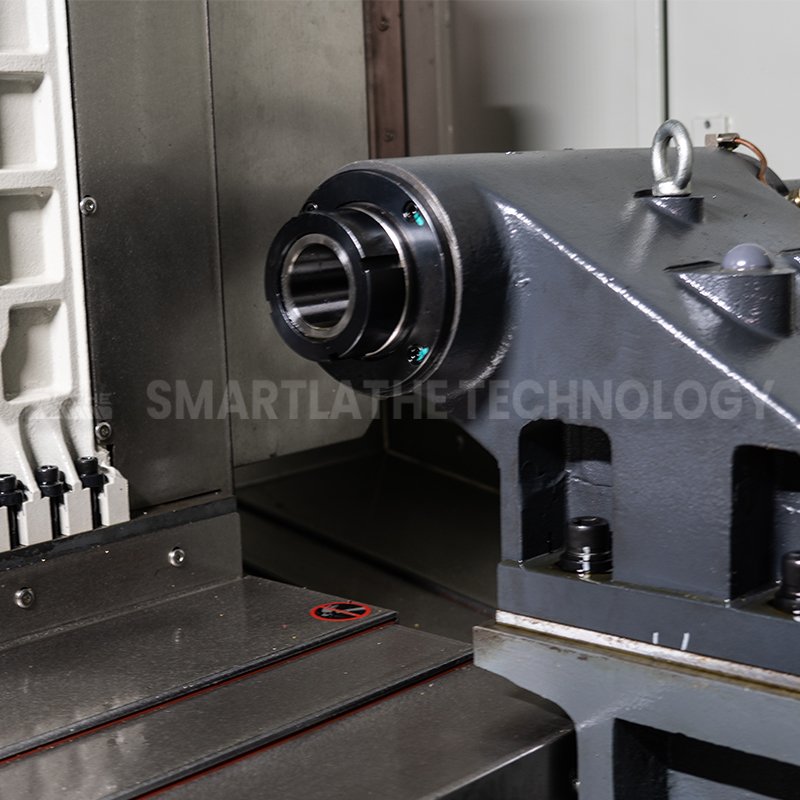

2. Load into the Chuck and Exit Factory