Analysis of Conversational Programming and Graphics Support Functions of Multiple CNC Lathe Operating Systems

In the increasingly competitive landscape of manufacturing, the efficiency and accuracy of CNC programming are crucial for production processes. To meet this demand, several CNC system providers have introduced conversational programming and graphical support features to enhance users' programming experience and production efficiency. This article provides an overview of seven major CNC system: Fanuc, Siemens, SYNTEC, Beijing-Fanch, GSK, KND, and HNC. So that you can understand the characteristics of different CNC systems and choose the system that is suitable for your CNC lathe.

Fanuc: Reliable Stability and Simplified Usability

Fanuc, as a Japanese CNC system manufacturer with a long history and rich experience, it is famous for its stability, reliability and high performance, and are widely recognized and applied around the world.

High precision and stability: Fanuc's CNC system is known for its excellent precision and stability. Whether in high-speed machining or complex machining tasks, Fanuc system delivers outstanding performance and reliability.

Conversational programming function: Fanuc CNC system has a certain degree of conversational programming function, allowing operators to program through simple instructions and parameters. This programming method is simple and intuitive and suitable for various application scenarios.

Wide range of applications: Fanuc CNC system is widely used around the world, especially in the automotive, aerospace, electronics and other industries. Whether it is processing large workpieces or small parts, Fanuc can provide efficient and precise processing solutions.

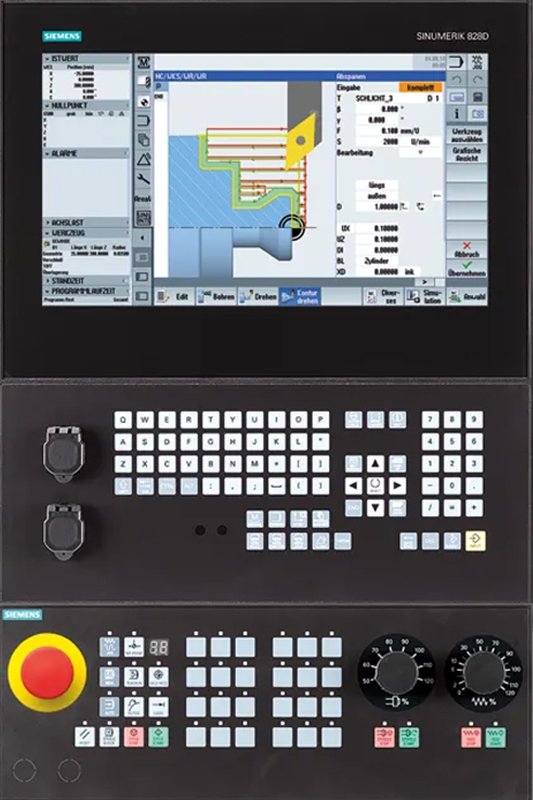

Siemens: Rich Graphical Support and Visual Programming Environment

Siemens CNC system is world-famous for its rich functions, flexibility, and advanced technology, and has been widely used around the world, especially in the fields of automobiles, aerospace, machinery manufacturing and other fields.

Rich functions and flexibility: Siemens CNC system has rich functions and flexibility and can meet various complex processing needs. Whether five-axis machining, multi-tasking or high-speed machining, Siemens systems deliver outstanding performance and efficiency.

Conversational programming function: Siemens CNC system provides rich conversational programming functions. Operators can create programs by inputting instructions and parameters through a simple conversation interface without having to understand the programming language in depth. This programming method is simple and intuitive and suitable for various application scenarios.

Powerful graphics support: Siemens CNC system has powerful graphics support, including advanced graphical interface and visual programming environment. Operators can quickly create and modify programs through an intuitive graphical interface, improving programming efficiency and accuracy.

Digital and intelligent production: Siemens CNC system supports the needs of digital and intelligent production and can realize factory automation, intelligent production management and other functions, helping customers improve production efficiency and competitiveness.

SYNTEC: Convenience of Natural Language Programming

SYNTEC is a Taiwan-based CNC system manufacturer founded in 1988. SYNTEC is widely welcomed and recognized for their stability, reliability and ease of use, and it has been widely used around the world.

Stability and Reliability: SYNTEC CNC system is renowned for their stability and reliability. Whether in high-speed machining or complex machining tasks, SYNTEC can provide stable and precise performance.

Natural Language Programming: SYNTEC supports natural language programming, enabling operators to write programs using instructions and statements similar to natural language. This programming method is intuitive and easy to understand, reducing the difficulty and learning cost of programming.

Graphics support: Although SYNTEC has relatively little graphics support, its systems are usually equipped with a basic graphical interface, allowing operators to operate and monitor through a graphical interface. This interface is simple and intuitive, making it convenient for users to operate and monitor.

Wide range of applications: SYNTEC is widely used in the Asian market, especially in Taiwan, China and other regions. Whether it is the processing of large workpieces or small parts, SYNTEC can meet customer needs and provide efficient and precise processing solutions.

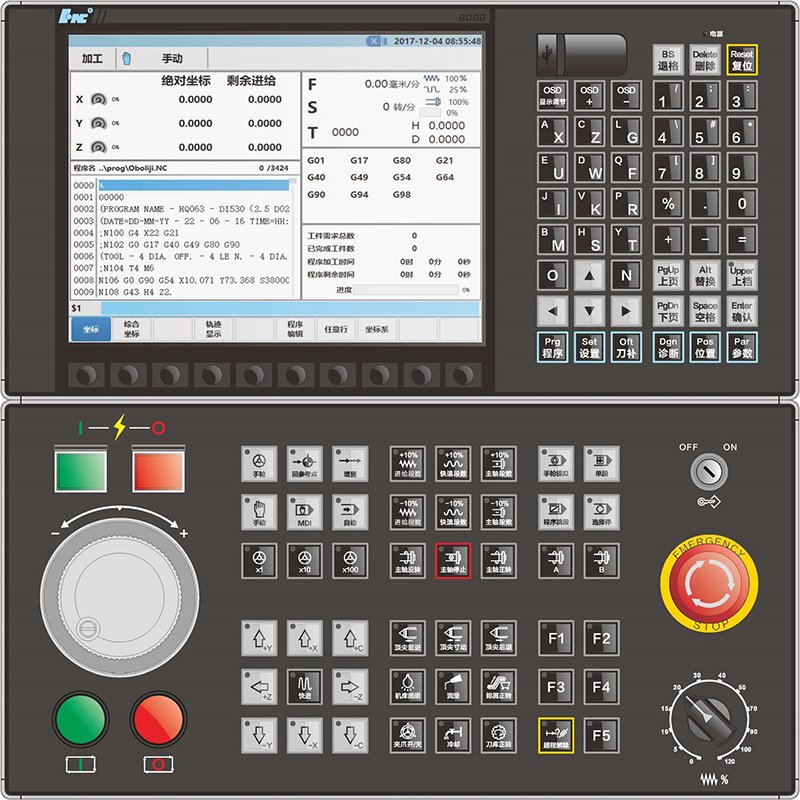

LNC: Balanced Stability and Cost-Effectiveness

Beijing-Fanch LNC CNC system is popular in the Chinese market for its affordable prices, stable performance and customization options.

Reasonable price and stable performance: LNC CNC system is known for its reasonable price and stable performance. It is suitable for application scenarios of small and medium-sized CNC machine tools.

Basic conversational programming: LNC CNC system provides basic conversational programming functions. Operators can create programs by inputting instructions and parameters through a simple conversational interface.

Limited graphics support: While LNC system may have relatively little graphics support, they are generally equipped with basic graphical interfaces for operating and monitoring tasks.

Customized options: LNC not only provides standard CNC system, but also provides customized CNC solutions to meet customers' specific machining needs.

GSK: User-Friendly CNC Programming Experience

GSK CNC system is widely welcomed for their simplicity, ease of use, and stable performance, and it is suitable for various processing scenarios.

Easy operation and stable performance: GSK CNC system is famous for its easy operation and stable performance. It is suitable for the processing needs of various small and medium-sized CNC machine tools. It gets a good reputation in the Chinese market.

Basic conversational programming: GSK provides basic conversational programming capabilities, allowing operators to create programs by entering instructions and parameters through a simple conversational interface without the need for in-depth knowledge of programming languages.

Limited graphics support: Although GSK may have relatively little graphics support, it is generally equipped with basic graphical interfaces for operational and monitoring tasks.

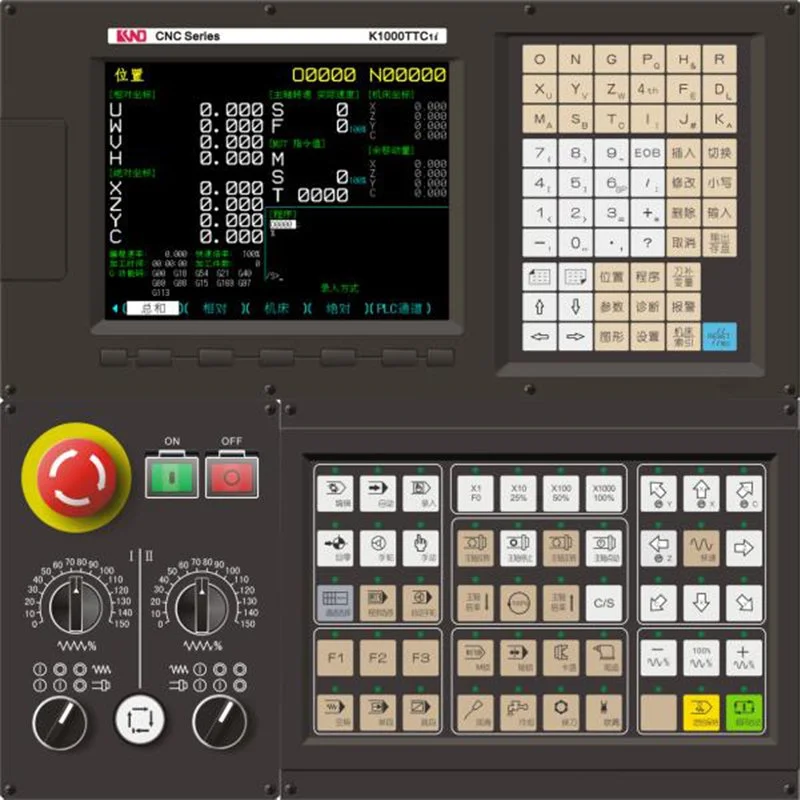

KND: Stable Performance at Affordable Prices

KND is a Chinese CNC system manufacturer founded in 1993, mainly targeting the Chinese domestic market.

Conversational programming: KND has basic conversational programming functions. Operators can create programs by inputting instructions and parameters through a simple conversation interface, making the programming process more convenient.

Limited graphical support: Although KND has relatively little graphical support, it is usually equipped with a basic graphical interface, allowing operators to operate and monitor through the graphical interface, improving the intuitiveness and convenience of operation.

HNC: Pioneering Domestic CNC Systems

HNC is a Chinese CNC system manufacturer founded in 1993. It has a certain influence on the Chinese market.

Conversational programming: CNC system usually has certain conversational programming functions, which allow operators to program relatively easily, improving the ease of use and efficiency of programming.

Limited graphics support: Although HNC CNC has relatively little graphics support, its system is usually equipped with a basic graphical interface, allowing operators to operate and monitor through the graphical interface, improving the convenience and intuitiveness of operation.

In summary, different CNC systems offer different capabilities and advantages in terms of conversational programming and graphics support. Users can choose the most appropriate CNC system based on their specific needs and preferences, thereby enhancing their CNC programming experience and achieving a more efficient and precise manufacturing process.

Smartlathe CNC lathe supports a variety of systems, and our professional team will help customers choose the most suitable CNC system for them based on their needs. If you have any questions, please feel free to contact us.