Applications of VMC 4th axis bridge broad

The 4th axis bridge broad generally refers to a machine tool accessory or structural support assembly used to mount a 4th axis (rotary axis), thereby expanding a three-axis machining center to 4th axis machining capability. The bridge plate can also be understood as a mounting platform connecting the four axes to the 4th axis tailstock, providing ample fixture expansion capabilities for the four axes.

Typical applications of four-axis bridge plates include home appliance parts, automotive parts, hardware parts, and aerospace. They offer significant advantages, particularly for the mass production of complex parts, reducing the number of clamping operations or increasing the number of clamps. Below are some examples illustrating the application range of 4th axis bridge broad.

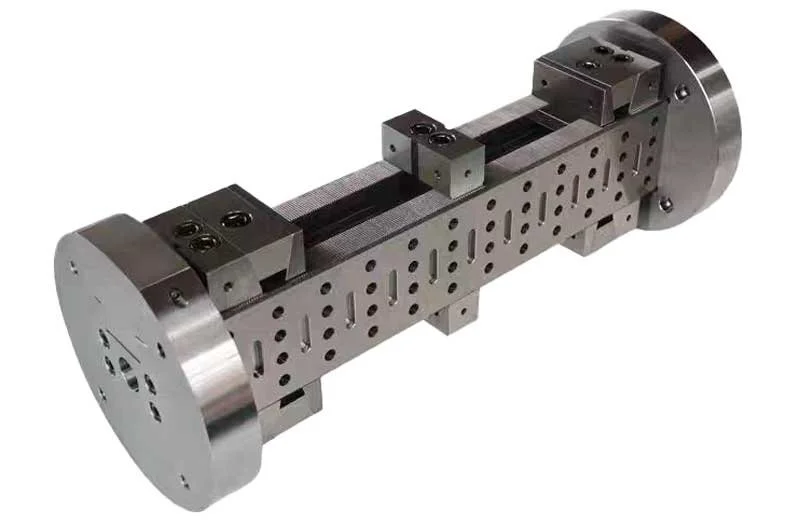

1. 4th axis bridge broad zero-point positioning fixture

The mounting base module is fixed on the 4th axis bridge broad , and the positioning pin is installed on the workpiece, mold or fixture . When the workpiece is placed in the base, the locking mechanism is driven by air pressure or mechanical spring, and the ball claw /locking pin enters the positioning cone hole to automatically complete "positioning + clamping".

When the air pressure is released, the spring or air pressure is released in the opposite direction, enabling quick replacement.

This four-axis bridge broad clamp has the following advantages:

Quickly change fixtures and workpieces to improve machine tool uptime.

High repeatability and reduced recalibration time.

4th axis bridge broad fixture is suitable for single medium-to-large parts that require multi-face machining. By rotating or linking the fourth axis, multi-face machining can be completed in one clamping , reducing the impact on accuracy caused by multiple clamping. This type of 4thaxis bridge broad fixture is usually paired with machine tools with a large-stroke spindle with rich tool extension capabilities and powerful cutting capabilities, such as Smartlathe 's VMC H series vertical machining centers.

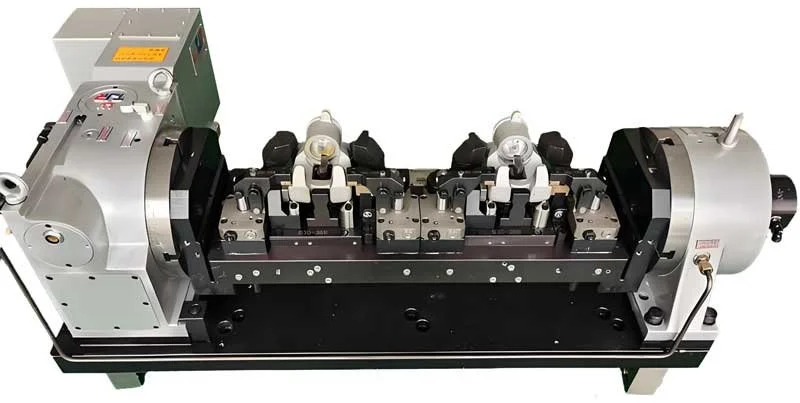

2. 4th axis bridge broad multi-station vise

The 4th axis bridge broad multi-station vise is a vise base with two or more sets of clamping units (usually 2 to 8 stations) that can clamp multiple workpieces at once, realizing multi-piece processing on one machine .

This 4th axis bridge broad clamp has the following advantages:

High-rigidity integral base design to prevent deformation.

Highly compatible and widely applicable.

High efficiency, multiple workpieces can be clamped at once, reducing the number of workpiece changes.

This 4th axis bridge broad fixture is suitable for processing small batches of small to medium-sized parts. It switches between different workstations by rotating the 4th axis. This fixture is generally compatible with machine tools that use fast traverse speed and fast tool change speed, such as Smartlathe 's VMC D series vertical machining centers.

3. Customized four-axis bridge broad fixture

Custom-designed fixtures are clamping devices tailored to specific workpieces, processes, or machine tool conditions. Unlike standard fixtures such as general-purpose vises or chucks, they are tooling specifically developed based on workpiece shape, machining requirements, and process routes.

The four-axis bridge plate custom clamp has the following advantages:

High clamping efficiency.

Easy to operate, replace parts, and test.

Compact structure, unified benchmark.

This type of 4th axis bridge plate custom fixture is suitable for mass production of parts, especially for large-volume die casting. It is particularly suitable for use with 4th axis bridge broda custom fixtures. This type of fixture is generally paired with machine tools with fast traverse speed and fast tool change speed to pursue the ultimate production efficiency. For example, Smartlathe 's VMC D series vertical machining center is very suitable for use with this type of fixture.

The above describes the application of 4th axis bridge broad in vertical machining centers. After understanding the application of four-axis bridge plates, do you know which type of 4th axis bridge broad fixture you need? If you still have no idea, no problem, you can send your product drawings and blank information to Smartlathe , and Smartlathe will recommend the most suitable machining solution and machining model for you.