VMC Hot-Swivel Tool Holder Type Introduction

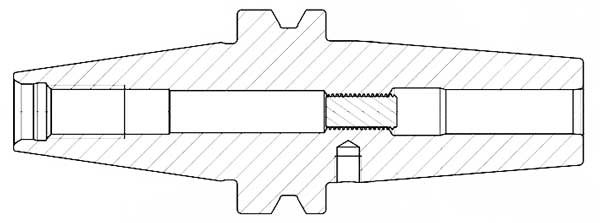

A thermosetting toolholder is a high-precision toolholder system that uses the principle of thermal expansion and contraction to clamp cutting tools. Its main features include high precision , high rigidity , good dynamic balance , stable clamping , and a compact structure . When clamping a tool, a thermosetting machine is used to heat the toolholder. After the toolholder end expands due to heat, the tool is quickly inserted into the expanded toolholder hole. After the toolholder cools, the hole shrinks and tightly clamps the tool, completing the installation. This type of toolholder is commonly used in mold manufacturing, aerospace, and automotive manufacturing.

The main ways to distinguish hot-fit tool holders are by their structural form, cooling method, and interface type.

1. Classification by structural form

Standard hot-fit tool holder

The most common type; suitable for general milling and drilling; simple structure and compact shape; most widely used in conventional machining.

Extended heat-fit tool holder

Designed for machining deep cavities or hard-to-access areas; the extension length can be extended while maintaining rigidity; standard extended lengths (L=100mm, 150mm, etc.) or custom lengths are available.

Slender

The tool holder has a slender tip to avoid interference and is commonly used in mold making or aerospace parts machining. These tool holders are typically paired with vertical machining centers with high-speed spindles, such as the Smartlathe VMC T600.

Heavy cutting type

Thicker walls provide stronger clamping force, making them suitable for high-torque cutting, such as rough milling and grooving. These toolholders are typically used with heavy- duty vertical machining centers, such as the Smartlathe VMC D600.

2. Classification by cooling method

External cooling type

It uses external nozzles or blades for lateral liquid cooling; it has a simple structure and low price.

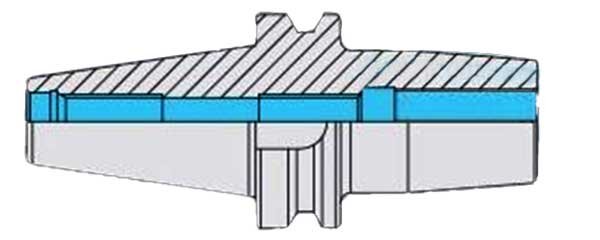

Center outlet type

Coolant is sprayed from the center of the spindle through the tool holder and the inner bore of the tool; it provides good heat dissipation and long tool life; it is widely used in high-speed machining and deep drilling applications.

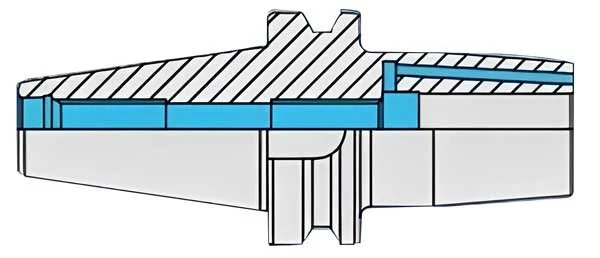

Annular cooling type

The tool holder has an annular cooling hole at the front end; coolant is sprayed out around the tool, which is suitable for high-speed adaptive cutting and deep cavity machining .

3. Classification by interface type

HSK series (HSK-A63, A100 )

BT series (BT40, BT50, etc.)

CAT series (CAT40, CAT50, etc.)

DIN69871 / SK series

CAPTO / PSC interface

The above explains how to differentiate between heat-fit tool holders. Choosing the right heat-fit tool holder can make product machining more convenient. For example, the Smartlathe VMC D600 model is suitable for machining mold blanks with standard, slender, and heavy-duty heat-fit tool holders with center coolers; the VMC T600 model is suitable for machining high-volume products such as copper and aluminum with standard and extended heat-fit tool holders with center coolers.

If you're looking to use a heat-fit toolholder in milling operations but are unsure how to choose the right one for your product, feel free to contact Smartlathe. We'll analyze your product requirements and provide suitable advice.