These parts are really hard to measure. What should I do?

Standard measuring tools such as micrometers or calipers are commonly used "tools" for measuring flat and parallel features or inner/outer diameters of workpieces. However, when measuring workpieces with complex shapes, such as curved surfaces or narrow grooves, it may be difficult for standard universal measuring tools to reach the accurate measurement position. It is relatively easier and more economical to choose dedicated non-standard measuring tools.

01 Measurement of pipe thickness

1-1 Pipe thickness micrometer

The cylindrical anvil can penetrate deep into the pipe for wall thickness measurement.

1-2 Pipe thickness caliper

The measuring claw of the main ruler is cylindrical, which can accurately measure the thickness of the pipe wall.

1-3 Pipe thickness table

The measuring anvil is at a 90° angle and can measure the thickness of pipe wall or bent plate.

02 Measurement of pipe inner diameter

2-1 Inner diameter caliper

The measuring claw is a blade type and is used to measure inner positions that are difficult to measure. Measuring claws of the same series also include pointed claw type and inner groove type.

2-2 Caliper-type inner diameter micrometer

The caliper-shaped measuring surface enables inner diameter measurements that cannot be achieved with a general-purpose micrometer.

2-3 Inner diameter table

It can measure the diameter of the bottom surface of the inner hole, and the inner diameter of the deep hole can be measured by connecting the extension rod.

03 Measurement of groove diameter

3-1 Flake micrometer

The measuring surface is a flake, which can easily and accurately measure the diameter of narrow grooves.

3-2 Flake calipers

The front end of the measuring claw is flake, which can easily reach the measuring position of the narrow groove to complete the measurement.

3-3 Flake table

The front end of the measuring claw is a flake, which can easily reach the measuring position of the narrow groove to complete the measurement.

04 Inside diameter measurement with inner groove lenght

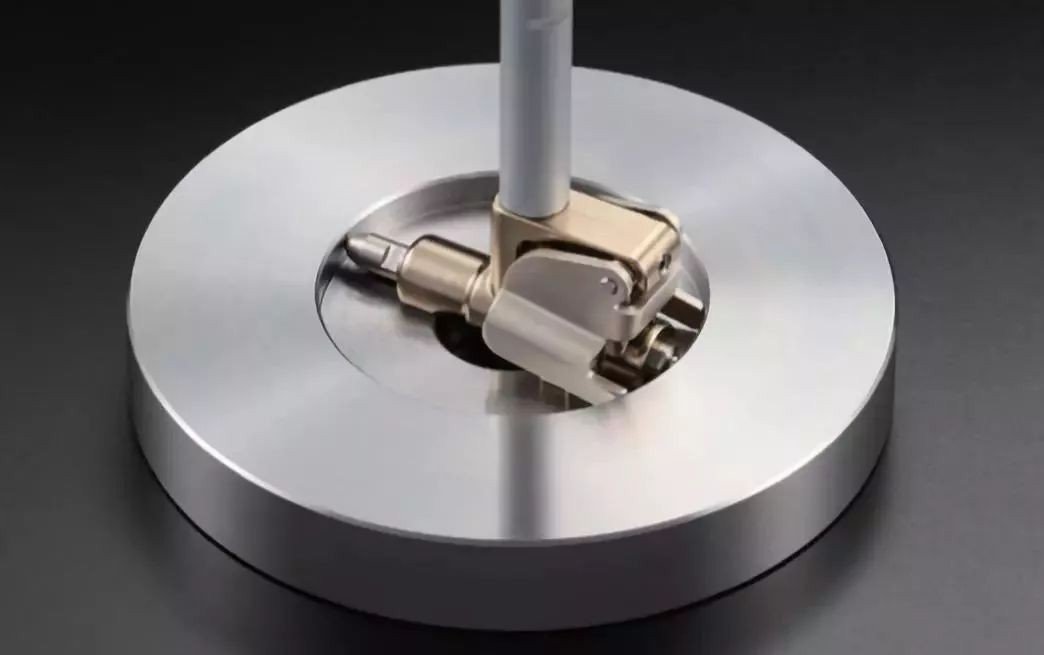

4-1 Groove micrometer

The micrometer screw and anvil with flange can measure the inner diameter of the groove and the depth and position relationship of the groove in the pipe.

4-2 Hook type vernier caliper

The front end of the measuring claw is hook-shaped, which can measure the size of the stepped groove of the inner diameter of the cylinder.

05 Spline measurement

5-1 Spline micrometer

Small diameter anvils make it easy to measure the diameter of spline shafts and grooves.

06 Measurement of hole center distance

6-1 Offset centerline caliper

With offset value setting function, the distance measurement value can be read directly.

6-2 Center-center back claw type offset caliper

With offset value setting function, the distance measurement value can be read directly.

6-3 Edge-center type back-jaw type offset caliper

The edge-center type measuring claw is suitable for measuring the distance between single holes, and the measuring claw is provided on the back of the ruler frame to facilitate reading the measurement results from above.