Turn Your Drawings into Solutions: SmartLathe Recommends the Ideal Machine

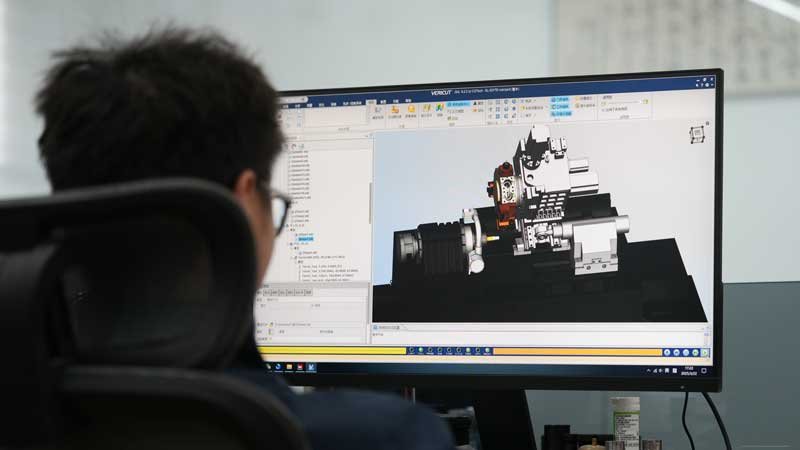

In actual production, customers often encounter such difficulties: "Get the drawings, but are not sure which machine tool to choose to complete the processing." SmartLathe knows this pain point well. We have a team of experienced engineers that can quickly analyze structural characteristics, material requirements and accuracy tolerances based on customer-provided parts drawings. Through professional process evaluation, we will clarify: what are the difficulties in processing workpieces; whether they need high-speed cutting or high-rigid cutting; whether they involve milling, tapping, turning and milling composite, or heart-wrenching processing; batch size and whether they are suitable for introduction of automation. Based on these analyses, we will recommend the most suitable model for our customers:

1. SL Series

SL Series - General-purpose Economical CNC Lathes:

(1) Mass production of small and medium-sized parts;

(2) Parts with low requirements for tolerances and surface quality;

(3) Economical choices suitable for primary processing enterprises and OEM factories.

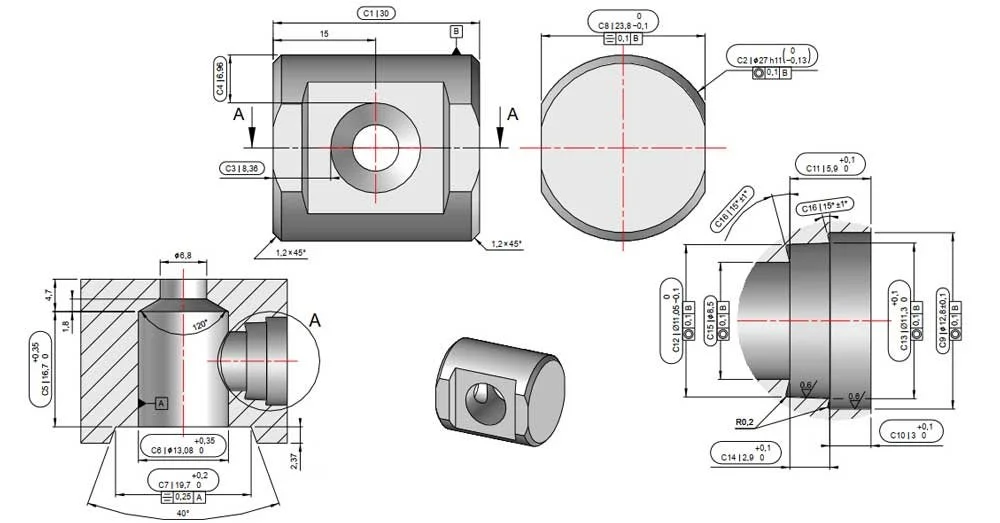

Corresponding related processing drawings:

(1) Turning-RBI-Drilling-Y-Axis Milling Process

(2) Part size: It is a small and medium-sized type, and the SL series is rigid enough.

(3) Accuracy requirements: Most dimensions are ±0.1 mm, and the local H11 is fully within the controllable range of the SL series 0.01 mm accuracy level.

(4) Complexity: The hole system is not complicated, and can be completed by SL powered tools or secondary processes; no DS/turning and milling composite machine is required.

(5) Efficiency: The SL series is low in cost and high in efficiency, and is suitable for this batch of parts.

2. ST Series

ST Series - General-purpose Economical CNC Lathes:

(1) Turning and milling composite, parts with high tolerance and surface quality requirements and mass-produced;

(2) CNC lathe with high rigidity, high speed and high stability

(3) Processing hard materials such as stainless steel, and parts with high tolerance and surface quality are required

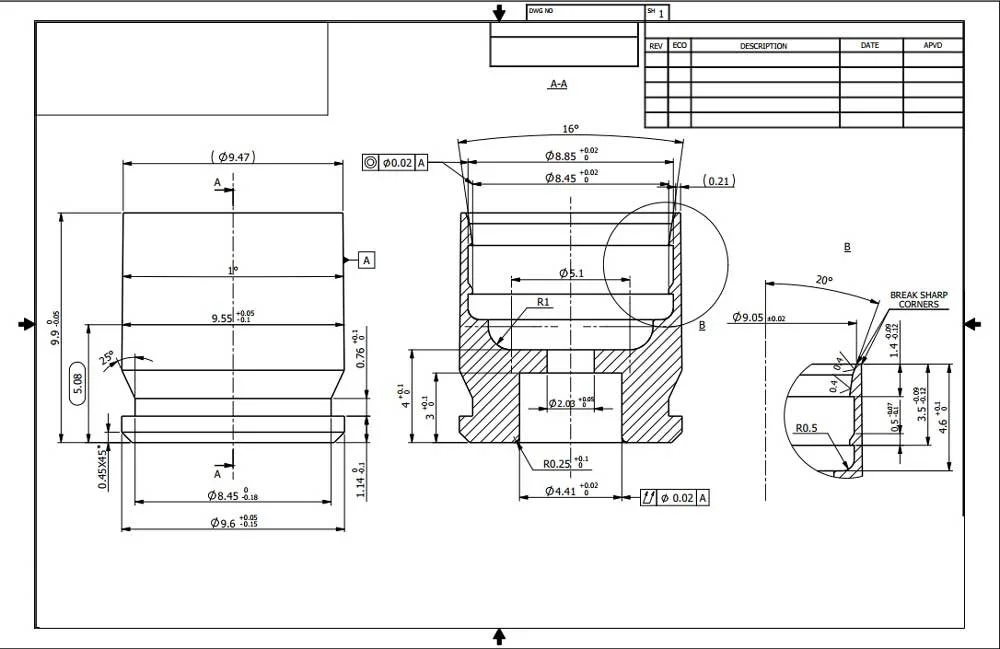

Corresponding related processing drawings:

(1) Turning-RBI-Drilling- Inner hole processing

(2) The ST series machines can be equipped with 8-inch chucks to process large-sized parts

(3) Parts with high positioning accuracy and suitable for high tolerance requirements, ±0.01mm tolerance can meet the requirements of parts

(4) Excellent surface quality, can stably achieve the surface roughness of Ra1.6, and meet the requirements of seals and fittings

(5) A multi-station turning and milling composite power turret can ensure a high-precision and high-efficiency processing environment

3. DS series

DS Series - General-purpose Economical CNC Lathes:

(1) The DS series belongs to high efficiency and high integration turning and milling composite machine tools

(2) CNC lathe with high rigidity, high speed and high stability

(3) Processing hard materials such as stainless steel, and parts with high tolerance and surface quality are required

(4) The structural design of the double spindle allows for the machining of the estimated front and back sides to be completed in one clamping, achieving high efficiency machining

(5) The countershaft can rotate and dock the spindle synchronously to ensure the requirements of high-precision processing, and can also be docked and rotated and clamped for special-shaped parts.

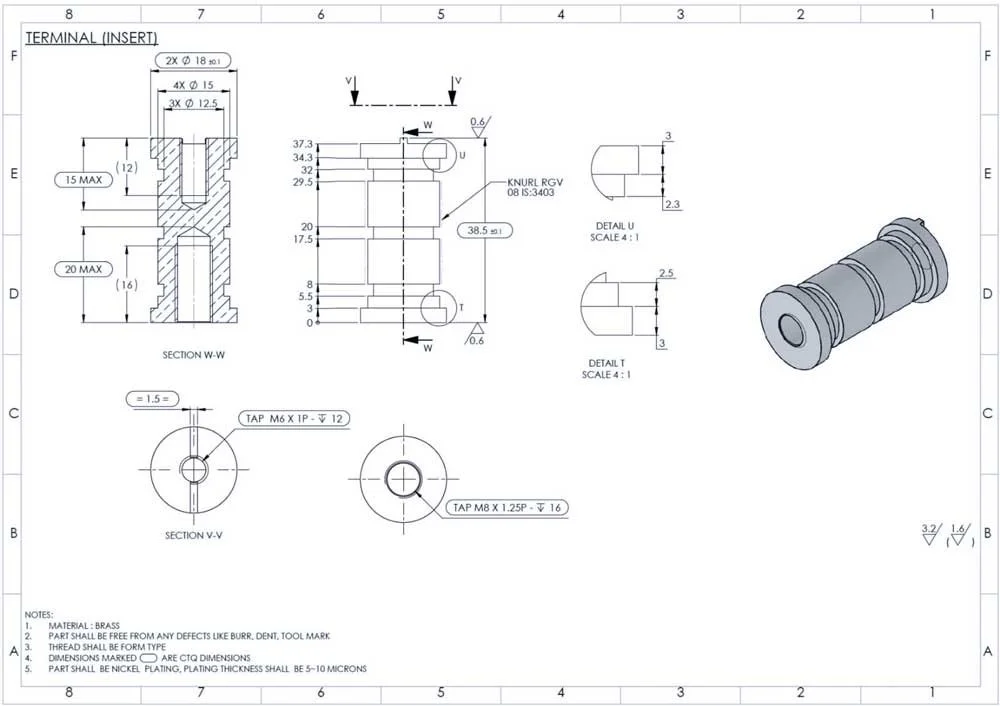

Corresponding related processing drawings:

(1) Turning processing-RBI-Drilling processing-Taping processing

(2) Complete the front and back processing of the workpiece in one clamping to ensure the coaxiality of the workpiece and avoid secondary clamping errors

(3) Parts with high positioning accuracy and suitable for high tolerance requirements, ±0.01mm tolerance can meet the requirements of parts

(4) Excellent surface quality, can stably achieve the surface roughness of Ra1.6, and meet the requirements of seals and fittings

(5) The structural design of turning and milling composite power turret and dual spindles equipped with multi-stations ensures a high-precision and high-efficiency processing environment

4. SW-Series

SW Series - General-purpose Economical CNC Lathes:

(1) The SW series is a high efficiency, high precision and high stability turning and milling composite machine tool

(2) The structural design of the guide sleeve can process slender parts and ensure high machining accuracy

(3) The spindle and sub-axis can be processed separately in separate processes, suitable for high-efficiency batch processing

(4) The design with power head can realize the machining function of turning and milling composite

(5) The dual spindles can also achieve high-precision synchronous rotation and docking processing, realize both front and back processing, and reduce secondary clamping

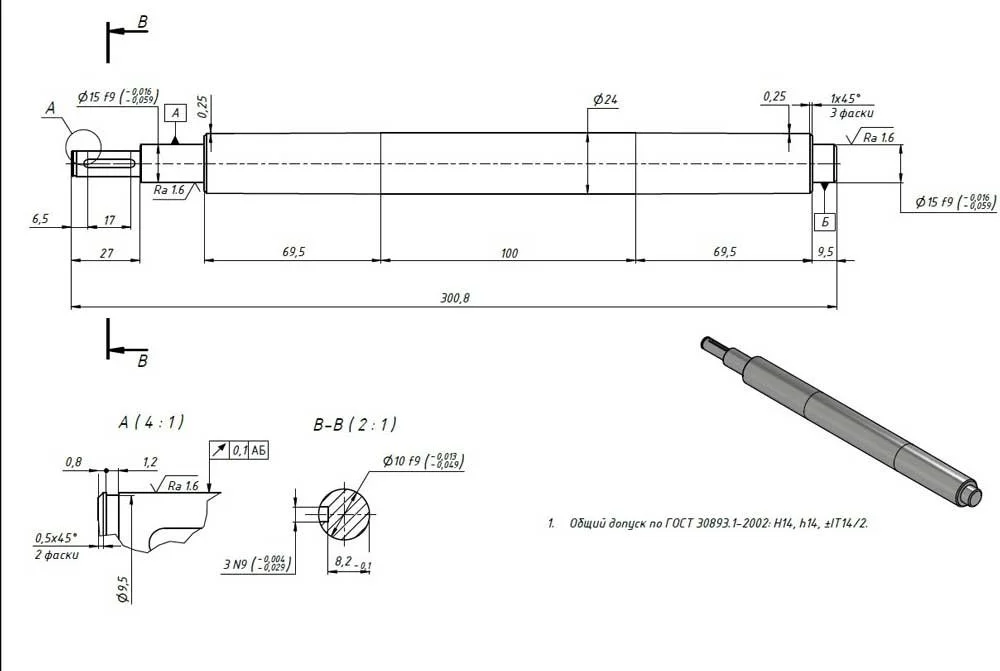

Corresponding related processing drawings:

(1) Turning processing-Y-axis milling

(2) Complete the front and back processing of the workpiece in one clamping to ensure the coaxiality of the workpiece, avoid secondary clamping errors, be equipped with feeder automation, and high efficiency processing

(3) Parts with high positioning accuracy and suitable for high tolerance requirements, ±0.01mm tolerance can meet the requirements of parts

(4) Excellent surface quality, can stably achieve the surface roughness of Ra1.6, and meet the requirements of seals and fittings

(5) Parts are slender and precision shaft parts, and the guide sleeves are machining to ensure machining accuracy and tolerance requirements.

This kind of "drawing analysis + model recommendation" service can not only help customers avoid blind investment, but also let them know clearly at the beginning of the project.SmartLathe is not only selling equipment, but also a process consultant and long-term partner around customers.