Application of Reaming

What is a reamer?

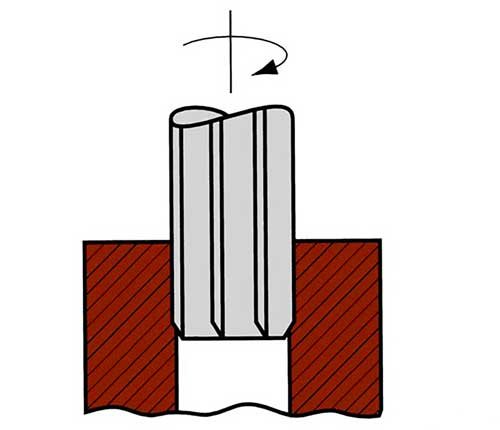

A reamer is a finishing tool used for hole processing. It is mainly used to precisely trim the inner holes that have been pre-drilled, bored or punched to improve the hole's dimensional accuracy, geometric shape accuracy (such as roundness, cylindricity) and surface finish. It is one of the core tools for high-precision hole processing in mechanical manufacturing.

The core role of reamer

Correction of geometric tolerance

During processing, the drill may run out and uneven axial pressure, causing the hole to become elliptical, conical or the axis to be tilted.

The reamer has a guide strip (such as the straight groove or spiral groove design of a machine reamer) that automatically corrects the roundness, cylindricity and straightness of the hole during cutting, and the error can be controlled to the micron level.

Correction of dimensional tolerance

The drill bit is easily affected by vibration, tool wear or uneven material hardness during processing, resulting in a slightly larger or smaller hole diameter with a certain tolerance (usually IT11-IT13 grade).

The reamer uses multiple cutting edges to evenly remove trace materials (usually 0.1-0.5mm) and correct the hole diameter to a higher precision (up to IT6-IT8 level), ensuring that the hole diameter strictly meets the design requirements.

Improve surface quality

Drilling produces spiral chips, resulting in residual tool marks on the hole wall, and the surface roughness is generally Ra 12.5-25μm.

The reamer has a lower cutting speed, uniform feed, and sharper cutting edge, which can reduce the surface roughness to Ra 0.8-3.2μm, meeting the requirements of high sealing or moving parts matching (such as hydraulic cylinders, bearing holes)

Application scenarios of reamer

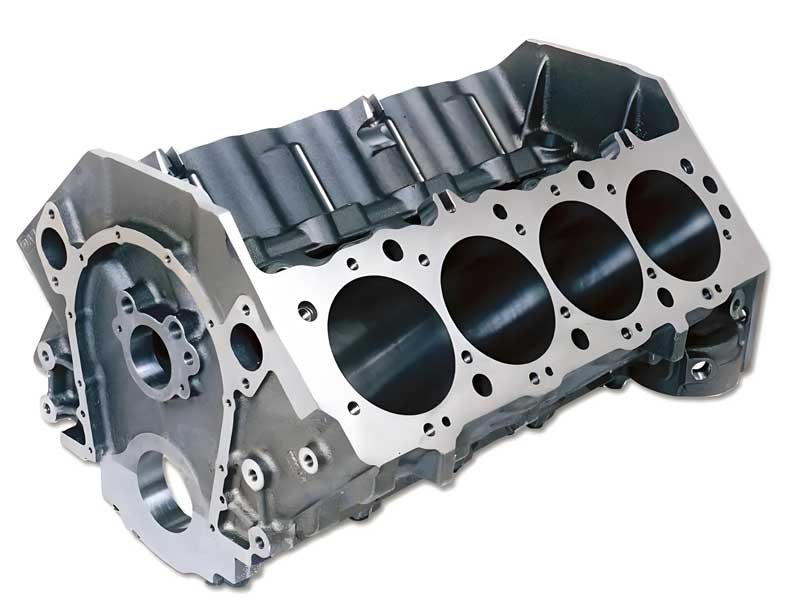

High precision matching

The bolt holes of the engine block and the bearing seat holes of the gearbox require strict tolerances (H7 level).

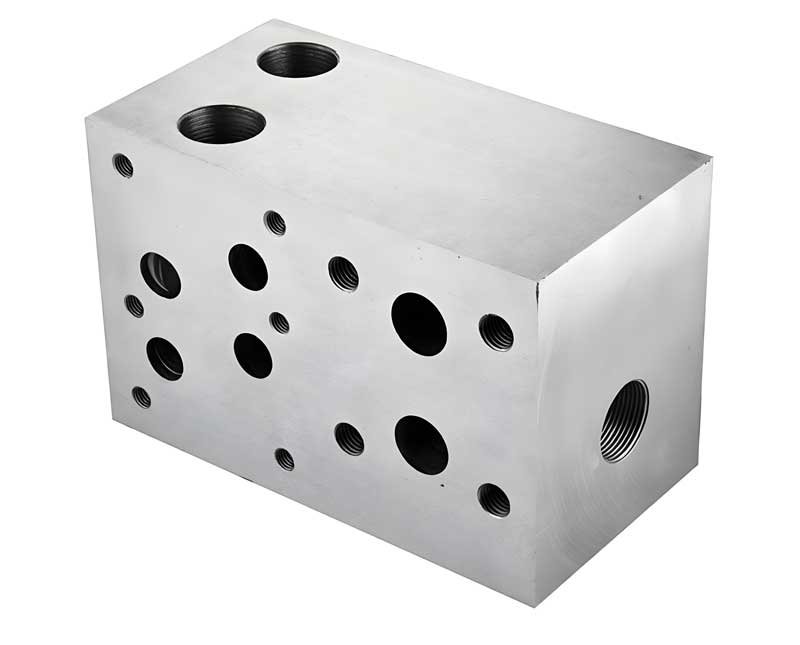

Sealing requirements

The oil channel holes of the hydraulic valve block and the sealing surface of the pump body rely on smooth hole walls to prevent leakage.

Complex structure

For thin-walled parts or deep hole processing, the reamer can avoid deformation and maintain dimensional stability