Spindle speed floating function SSV

1. Spindle speed floating function SSV

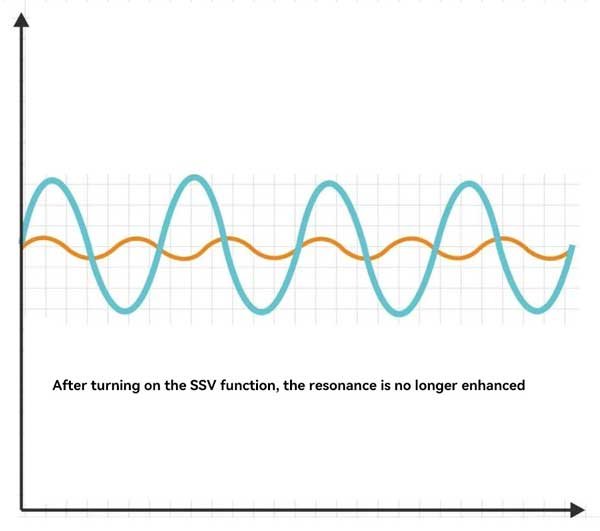

In the application of CNC lathes, the spindle speed variation (SSV) function effectively breaks the resonance frequency during the processing, reduces chattering, and improves processing stability by introducing small periodic fluctuations around the spindle speed. Based on the set speed, the system makes the spindle speed fluctuate periodically within a small range instead of maintaining a constant speed.

2. Features

It is different from the constant surface speed function G96 (Constant Surface Speed, CSS). The surface speed function automatically adjusts the spindle speed according to the change of workpiece diameter to keep the cutting speed constant, thereby ensuring the cutting quality; it does not dynamically adjust according to the periodic fluctuation of the spindle speed.

In the absence of a tail top, when turning long shafts and thin-walled parts, the relative movement of the tool and the workpiece is constantly changing its rhythm, thereby "disturbing" the resonance. This can effectively break the resonance frequency during the processing, reduce vibration marks, and improve processing stability.

3. Processing effect

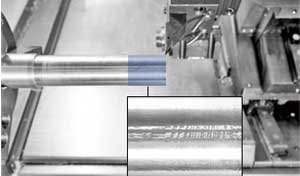

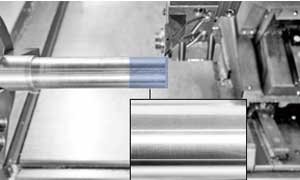

In actual processing, if the spindle speed floating function SSV is not enabled, the outer circle surface will show regular ripples; after enabling it, these regular ripples will disappear and the outer circle surface will become smooth and flat.

4. Application

Our SmartLathe machine is equipped with SmartBrain control system, which supports the combined use of the **spindle speed floating (SSV) function and the **constant linear speed (G96) function. The dual-function collaboration can not only significantly improve the processing efficiency, but also effectively improve the surface finish, especially for processing scenarios that are prone to vibration, such as slender shafts, thin-walled parts and threads. This function combination can significantly enhance the stability of the processing process and improve the processing quality and consistency of parts.