How to Select Appropriate Machining Parameters for Deep Hole Drilling

1. Deep Hole Drilling

Deep hole drilling refers to a drilling technique where the depth-to-diameter ratio of the hole exceeds 10:1. This process places higher demands on tool structure, chip evacuation capability, coolant and lubrication systems, as well as machine rigidity. To ensure smooth chip removal and thermal stability during prolonged drilling operations, deep hole drilling commonly utilizes a high-pressure internal coolant system, which provides effective cooling and chip evacuation at the cutting zone.

2. Deep Hole Drilling Methods

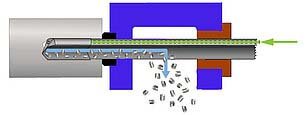

Gun Drill: Single cutting edge with V-shaped flute, straight shank design; internal high-pressure coolant supply with external chip evacuation; offers high precision and excellent surface finish.

BTA Drill: Multi-edge assembled head with support guide bush; external coolant supply with central chip evacuation; high cutting efficiency and suitable for heavy-duty machining.

3. Application Fields

Mainly applied in the automotive industry, mold manufacturing, aerospace, medical devices, construction machinery and hydraulic systems, and energy equipment.

4. Selection of Machining Parameters

The selection of machining parameters has a decisive impact on hole quality, machining efficiency, and tool life.

Depending on the material being processed, deep hole drilling parameters should be precisely matched according to industry standards. Key factors such as material diameter, hardness, thermal conductivity, and cutting characteristics must be taken into account to reasonably set critical parameters like feed rate and coolant pressure, ensuring efficient and stable drilling performance while extending tool life.

|

Material |

Brass |

Aluminum |

Carbon and Alloy Steels |

Gray and Ductile Cast Irons |

|

Cutting Speed |

80-150mm/min |

80-160mm/min |

70-100mm/min |

70-100mm/min |

|

Feed Rate (mm/rev) |

||||

|

Drill Diameter(mm) |

/ |

/ |

/ |

/ |

|

1.9-2.49 |

0.003-0.015 |

0.002-0.012 |

0.003-0.007 |

0.005-0.019 |

|

2.5-2.99 |

0.005-0.02 |

0.004-0.026 |

0.005-0.01 |

0.008-0.026 |

|

3.0-3.49 |

0.006-0.03 |

0.006-0.037 |

0.007-0.013 |

0.009-0.038 |

|

3.5-3.99 |

0.007-0.045 |

0.007-0.055 |

0.009-0.015 |

0.011-0.046 |

|

4.0-4.49 |

0.008-0.05 |

0.008-0.071 |

0.012-0.019 |

0.012-0.05 |

|

4.5-4.99 |

0.009-0.057 |

0.009-0.094 |

0.014-0.02 |

0.016-0.057 |

|

5.0-5.99 |

0.01-0.069 |

0.01-0.109 |

0.016-0.026 |

0.018-0.068 |

|

6.0-6.99 |

0.012-0.079 |

0.012-0.125 |

0.018-0.028 |

0.024-0.074 |

|

7.0-7.99 |

0.014-0.092 |

0.018-0.130 |

0.021-0.035 |

0.028-0.085 |

|

8.0-8.99 |

0.016-0.101 |

0.02-0.144 |

0.024-0.036 |

0.032-0.096 |

|

9.0-9.99 |

0.018-0.113 |

0.023-0.158 |

0.027-0.04 |

0.036-0.114 |

|

10.0-11.99 |

0.02-0.139 |

0.025-0.174 |

0.03-0.049 |

0.05-0.120 |

|

12.0-13.99 |

0.024-0.156 |

0.03-0.182 |

0.036-0.06 |

0.06-0.138 |

|

14.0-15.99 |

0.028-0.179 |

0.035-0.194 |

0.042-0.071 |

0.07-0.154 |

|

16.0-17.99 |

0.033-0.199 |

0.05-0.209 |

0.048-0.079 |

0.079-0.17 |

|

18.0-19.99 |

0.036-0.224 |

0.054-0.228 |

0.054-0.091 |

0.09-0.191 |

|

20.0-23.99 |

0.04-0.249 |

0.06-0.254 |

0.06-0.107 |

0.106-0.207 |

|

24.0-27.99 |

0.048-0.291 |

0.072-0.295 |

0.069-0.117 |

0.12-0.221 |

|

28.0-31.99 |

0.056-0.327 |

0.084-0.360 |

0.079-0.134 |

0.14-0.237 |

|

32.0-39.99 |

0.064-0.380 |

0.096-0.455 |

0.085-0.154 |

0.16-0.245 |

|

40-50 |

0.072-0.399 |

0.105-0.488 |

0.091-0.169 |

0.18-0.254 |

For initial drilling, it is recommended to reduce the spindle speed and feed rate; once stable, efficiency can be increased. When machining titanium alloys or stainless steel, it is crucial to control heat buildup to prevent workpiece hardening or tool chipping.

5. Machining Solution

At SmartLathe, we tailor deep hole drilling solutions based on the specific material properties you provide. We will recommend the most suitable machine model and optimized machining parameters to ensure efficient and stable performance.