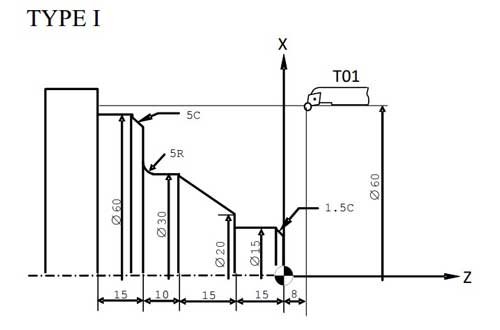

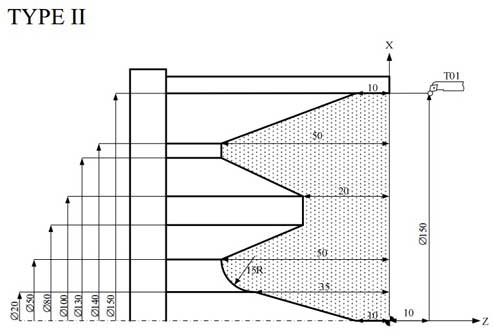

G72 radial roughing dynamic machining

1. What is G72?

G72 is a rough turning cycle command in CNC lathes, mainly used to automatically complete rough machining of external circles or end faces. Different from programming by cut, G72 can generate multiple tool paths at one time by setting cutting areas and parameters, realizing intelligent machining of "automatic layering and automatic feed".

2. G72 code application scenarios

It can be used for outer diameter turning. When the rough diameter is large and multiple cuts are required to reach the finished size, G72 can automatically rough turn in layers to improve efficiency. Such as stepped shafts, cylindrical shafts, shaft parts, etc.

It can also be used for end face roughing. When the end face of the workpiece is wide and a large amount of material needs to be removed, G72 can be used for rough turning along the Z direction. It is suitable for processing larger flanges, disc parts or end face grooves. Using G72 rough turning can greatly simplify programming.

3. G72 code format

G72 W(△d)___R(e)___H(h)___

G72 P(ns)___Q(nf)___U(△u)___W(△w)___F(f)___S(s)___T(t)___

When H=0, the tool is retracted at 45° in each cycle, and the machining trajectory is drawn at the end. The first and second axes of the plane must be monotonically increasing or monotonically decreasing. An alarm is triggered when there is a groove.

When H=1, each cycle cuts according to the finishing trajectory. The first axis of the plane must be monotonically increasing or monotonically decreasing, and the second axis of the plane can be non-monotonic.

4. New features of G72

In Smartlathe's self-developed SmartBrain system, we have launched a new H2 function for the G72 radial cycle roughing instruction - G72 three-type radial roughing dynamic processing. Compared with the traditional way, H2 significantly reduces the retracting and feeding time through reciprocating cutting, and the roughing efficiency is greatly improved. This innovative function is independently developed by the Smartlathe team to bring users a more efficient and intelligent processing experience.