What is 5C and 16C collet?

5C and 16C are two classic American standard collet system models, designed by Hardinge Inc. in the United States and widely used in various precision turning equipment worldwide. They are precision fixtures used to hold cylindrical workpieces, relying on elastic deformation to generate clamping force, featuring high accuracy, stable clamping, and suitability for high-speed machining.

1. 5C and 16C collet chucks

The clamping diameters of 5C and 16C collet chucks are expressed in inch values. The maximum clamping diameter of 5C is approximately 1.125 inches (28.5mm), and for 16C it is approximately 1.625 inches (41.3mm).

The 5C collet chuck is not suitable for high-speed or heavy-duty cutting; while the 16C is suitable for heavy cutting or power clamping systems and high-speed applications.

Common spindle nose types for 5C collet chucks are A2-4/A2-5; for 16C collet chucks, they are A2-5/A2-6.

2. 5C and 16C collets

5C and 16C collets are made of high-strength spring steel.

The front end has 3–6 longitudinal slots to allow radial elasticity; the rear end has threads for tightening. The outside surface is tapered to fit the inner taper of the collet chuck.

Working principle of the collet: The collet is inserted into the collet chuck and pulled from the rear by a drawbar or hydraulic mechanism. The tapered surface is drawn into the chuck body, causing axial movement, radial contraction, and clamping of the workpiece.

3. Specifications of 5C and 16C Collets

|

Item |

5C Collet |

16C Collet |

|

Standard System |

ANSI Hardinge Standard |

ANSI Hardinge Standard |

|

Max Clamping Diameter |

Ø26.988 mm (1-1/16 inch) |

Ø41.275 mm (1-5/8 inch) |

|

Typical Clamping Range |

Ø1 mm – Ø26 mm |

Ø3 mm – Ø40 mm |

|

Outer Diameter |

Ø31.4 mm |

Ø42.9 mm |

|

Overall Length |

83.3 mm (3.281 inch) |

121.5 mm (4.78 inch) |

|

Rear Thread Specification |

1.238" × 20 UNEF (external thread) |

1.690" × 20 UN (external thread) |

|

Clamping Method |

Draw-back type |

Draw-back type |

|

Matching Collet Chuck |

Dedicated 5C Chuck |

Dedicated 16C Chuck |

|

Compatible Spindle Nose |

A2-4 / A2-5 |

A2-5 / A2-6 |

|

Accuracy Grade |

≤ 0.01 mm (High-precision model ≤ 0.005 mm) |

≤ 0.01 mm (High-precision model ≤ 0.005 mm) |

|

Typical Workpiece Size |

Small parts (e.g. Ø3–25 mm) |

Medium parts (e.g. Ø20–40 mm) |

|

Collet Weight (approx.) |

Approx. 0.5 kg |

Approx. 1.2–1.5 kg |

|

Speed Capability (ref.) |

≤ 6000 rpm |

≤ 5000 rpm |

|

Thru-hole Option Available |

Yes (through and blind types available) |

Yes (through and blind types available) |

|

Versatility / Compatibility |

Very high (widely used in jigs and lathes) |

High (commonly used in CNC lathes and live heads) |

4. Convert an A2-5 chuck to a 5C collet chuck

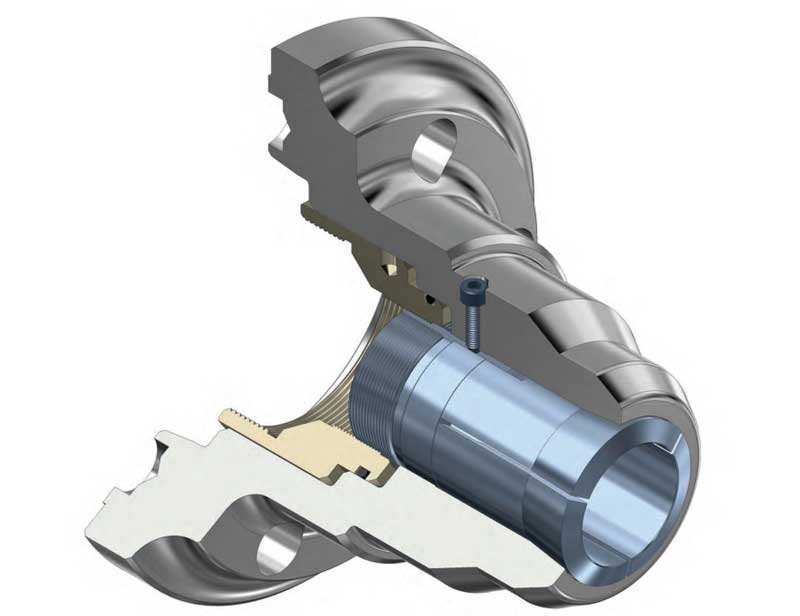

Uses a traditional draw-back design, where the 5C collet is clamped by pulling back the drawtube hydraulically and released by pushing forward. The nose of the collet chuck has a small diameter and thin profile, providing excellent tool clearance (minimizing collision risk when tools approach the workpiece).

At SmartLathe, we offer 5C collet chucks with an A2-5 mount, which can be directly bolted onto the A2-5 spindle flange without requiring an additional adapter plate. A custom adapter nut is needed to match the machine's drawbar thread specifications, ensuring seamless connection with the hydraulic cylinder.