What is ER collet with CNC lathe

ER collets are commonly used in CNC machines as a tool holder for high precision drilling, milling, and grinding applications.

For what purposes does a collet?

The subtype of chuck known as a collet is a cylindrical sleeve. With a pointed outer surface and a tube-shaped inner surface, the sleeve is used to create a collar around a tool or gadget. Collets have a conical outer surface that often provides a strong gripping force on the thing they are grasping when tightened.

Applications of Collet

Collets come in a variety of shapes and sizes, just like other tooling mechanisms, making them suitable for use in a wide range of sectors that need clamping equipment. They are frequently employed in numerous machining industries, including:

Metalworking: Since many tools need to have clamping capabilities, collets have several uses in this sector of the economy. Typically, round bars and tools are fastened by standard metalworking collets. For particular projects, square and hexagonal collets are employed as well. E-collets, step collets, and soft collets are also used in metalworking applications to hold larger components in position while performing certain tasks.

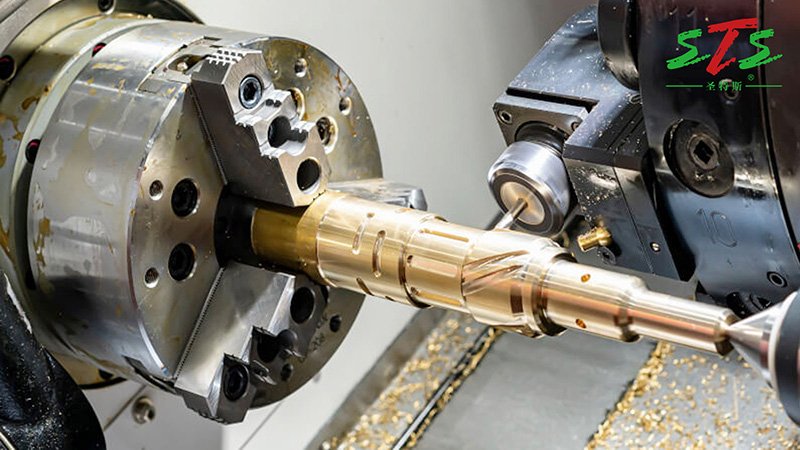

ER collets: When it comes to clamping tools, these gadgets are frequently regarded as the greatest option by producers. A CNC tool called an ER collet is used to retain different milling machine parts. These contraptions are made up of a primary body and a dangerous end. The primary shaft is secured by the nut. The ER-8 through ER-50 series of ER collets are available, with each model number referring to the holder's diameter size in millimeters.

Specification Collet

ER 20 collets

To firmly retain round-shank tool bits in milling machines, install into an ER-20 collet chuck or holder. These collets comply with both ISO and DIN dimensional requirements to guarantee compatibility with milling machines and tooling produced globally.

Collets with coolant maintain tool temperature to increase tool life.

ER 25 collets

ER-25 collet chuck milling machines should be used with these collets. They compress to hold round-shank drill bits, end mills, reamers, and taps thanks to their rounded face and adjustable body.

These collets comply with both ISO and DIN dimensional requirements to guarantee compatibility with milling machines and tooling produced globally.

ER 32 collets

To firmly hold round-shank tool bits in milling machines, install into an ER-32 collet chuck or holder.