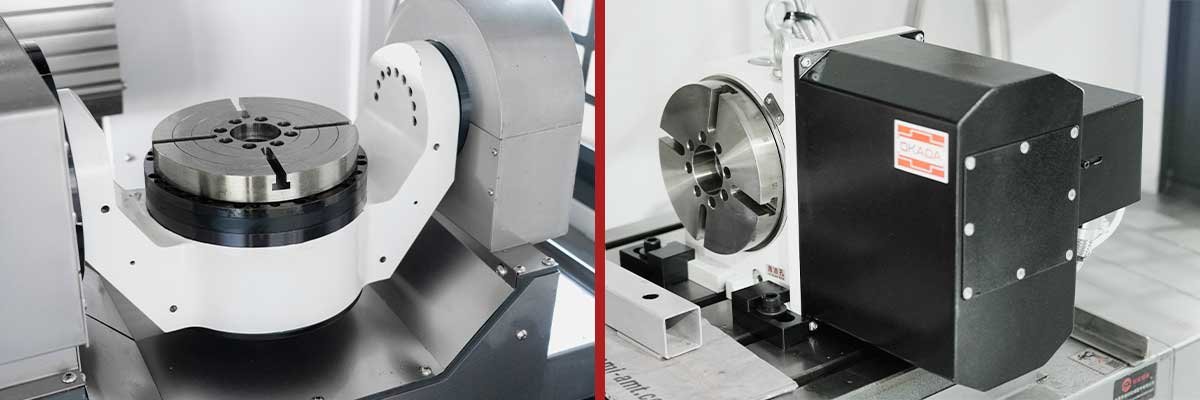

How to Choose Hard Jaws and Soft Jaws, and How to Properly Adjust

Soft jaws are versatile and can be machined to fit specific workpieces, ensuring precise gripping and reducing the risk of damage, making them ideal for delicate or unique tasks. Hard jaws, on the other hand, are pre-hardened, durable, and suitable for repetitive or high-torque operations, providing strong and consistent clamping. Soft jaws excel in flexibility and customization, while hard jaws prioritize longevity and efficiency for standard applications. Both are essential depending on the machining requirements.

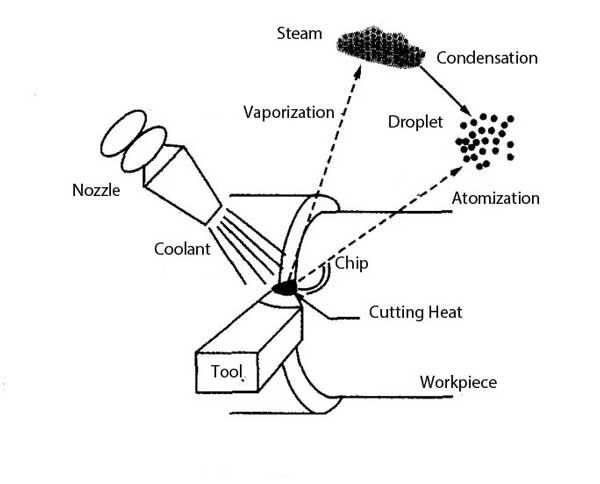

Oil Mist Generated in CNC Lathe Processing

During metal processing with CNC lathes, a large amount of cutting fluid is used, leading to the formation of numerous oil mist particles in the air. Metalworking lubricants are complex mixtures that, in addition to hydrocarbons, often contain sulfonates, fatty amines, nitrates, dyes, biocides, and other chemicals. If the lubricant has been in use for some time, due to the oxidation of hydrocarbons, microbial growth, or contamination by external impurities, it may contain additional chemicals that are harmful to both humans and the environment. Therefore, controlling the concentration of oil mist in metalworking workshops is a crucial measure for ensuring occupational safety and health in production enterprises.

Surface Treatment for Workpieces After Vertical Machining Center (VMC) Processing

CNC machining processes are capable of producing precise parts and components with strict tolerances of ±0.025 mm and intricate details. However, parts manufactured by a vertical machining center (VMC) often exhibit noticeable machining marks. Therefore, surface treatment is a critical aspect of the manufacturing process, enhancing the aesthetic appeal, corrosion resistance, wear resistance, and other physical and functional properties of metal parts post-VMC processing. Different types of surface treatments involve varying procedures and results, making it essential to understand the basics to select the most suitable option.

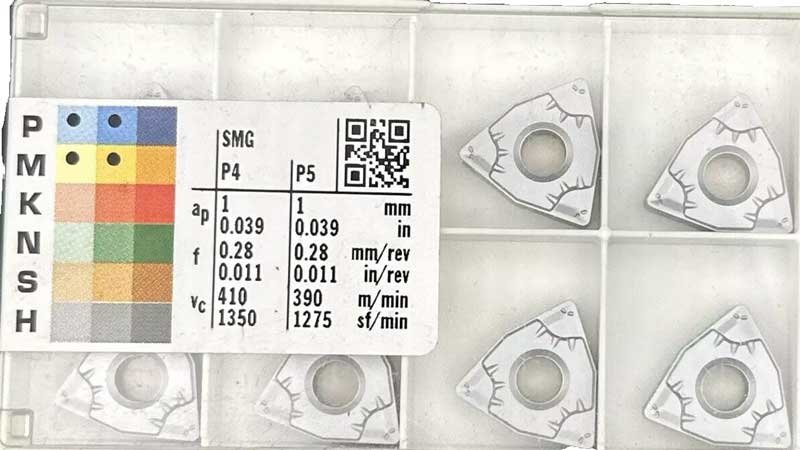

What are the main CNC machining parameters? (Turning)

CNC machining relies on precise parameter settings to ensure accuracy and repeatability. The proper setting of machining parameters determines the quality and efficiency of the machining process. These settings include spindle speed, feed rate, depth of cut and cutting tool path.

Classification of Cutting Fluids

Cutting fluids are widely used in CNC lathe machining environments, continuously injecting vitality and efficiency into metal cutting operations through flexible application methods such as precise injection, fluid spraying, or fine mist.

Types and Characteristics of Vertical Machining Center (VMC) Tool Holders

A VMC tool holder is a critical device used in VMC for securing and clamping tools. Its primary function is to firmly fix the tool to the spindle during machining, ensuring the concentricity and rigidity between the tool and the spindle. This is essential for maintaining machining accuracy and stability.

Classification of Milling Cutters for Vertical Machining Centers (VMC)

Milling tools, as critical tools for Vertical Machining Centers (VMC), play an essential role in executing a variety of complex machining tasks. From basic slot milling and chamfering to intricate 3D contour machining, different types of milling cutters, with their unique designs and functions, meet diverse machining needs.

Characteristics of Thread Milling on VMC

Thread milling on a vertical machining center (VMC) is a high-efficiency process that uses a milling cutter to machine threads. Compared to traditional thread machining methods, such as tapping and turning, thread milling on a VMC offers several advantages

How can a U-drill be machined on a CNC lathe?

When using a U-drill for drilling on a CNC lathe, the maximum radial adjustment for drilling depends on the overlap between the U-drill’s central and peripheral inserts. Radial adjustment affects the cutting force, so it’s recommended to choose a lower feed rate within the suggested range.

Plane Definitions of G17, G18, and G19

These three commands restrict tool movement to the specified plane, thereby preventing incorrect plane selection during machining, which could otherwise lead to tool collision or workpiece damage. Therefore, using the G17, G18, and G19 codes is essential for ensuring machining quality and safety.

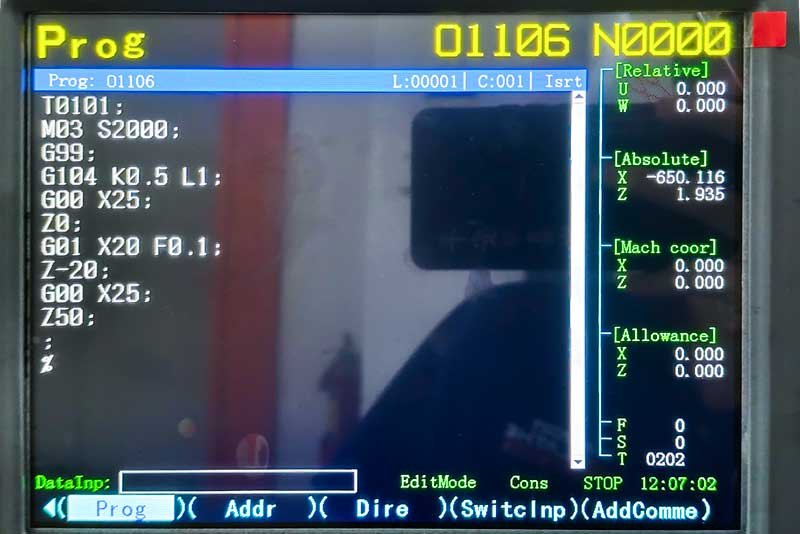

Chip-Breaking Function of the Smartbrain CNC System

During the machining process, this function controls the flow and breaking of chips through system codes, creating an effective chip-breaking process.

Principles for Selecting Cutting Tools

Any time a tool stops working, production halts. However, not all tools have the same level of importance. The tool that is used for the longest cutting duration has a greater impact on the production cycle, so its performance should be prioritized under equal conditions. Special attention should also be given to tools used for processing key components and those with the strictest tolerance requirements. Additionally, tools with poor chip control, such as drills, grooving tools, and threading tools, should be closely monitored because poor chip control can cause tool wear or machine downtime.

Differences Between Mechanical Spindle and Electric Spindle in a VMC

A mechanical spindle in a VMC (Vertical Machining Center) typically consists of the spindle, bearings, and transmission components such as gears or pulleys. Its operation relies on an external motor that drives the spindle rotation through transmission devices (e.g., gears or belts). This type includes gear-driven, belt-driven, and direct-drive systems.

What is a tapping protector and what does it do?

The tool holder used will have an overload protection collet, functioning similarly to the tapping protector; it adjusts torque, increasing torque clockwise and decreasing it counterclockwise.

During processing, if torque increases, the tool holder will rotate freely, effectively protecting the tap and extending its lifespan. The torque will also vary to provide overload protection.

The Tool Changing System, Coolant Delivery System, and Chip Removal System of Vertical Machining Centers (VMC)

To achieve optimal machining performance, a Vertical Machining Center (VMC) is typically equipped with a high-quality tool changing system, coolant delivery system, and chip removal system. Additionally, factors like spindle speed, axis travel, and workpiece capacity are critical when considering a VMC.

Selection of VMC Milling Cutter Flute Count

Milling cutters come in various flute counts, with common options including single-flute, two-flute, three-flute, four-flute, and six-flute cutters. Each flute count has different characteristics and usage scenarios.

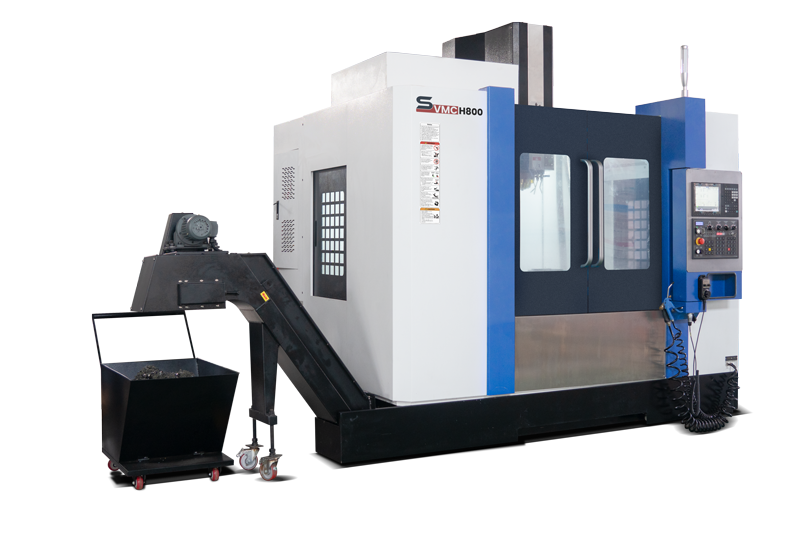

Advantages and Applications of VMC (Vertical Machining Centers)

VMC machines provide higher precision and accuracy in machining operations. With advanced CNC technology and precise control systems, these machines can meet strict tolerance requirements and continuously produce high-quality parts. The accurate positioning capability of cutting tools enables VMC machines to perform complex machining tasks with minimized errors or deviations, making them suitable for tasks requiring high detail.

Brief Introduction to VMC Machines

A VMC machine, also known as a Vertical Machining Center, is a type of CNC (Computer Numerical Control) milling machine that removes material from a workpiece using a vertically oriented spindle. It is widely used in various industries for precision cutting, drilling, and shaping operations. The primary function of a VMC machine is to automate the manufacturing process and produce complex parts with high accuracy and efficiency.

Installation Method of Cutting Tool ER Collet

The ER collet is a common clamping device used to hold tools or workpieces, widely applied in CNC machines, milling machines, and drilling machines. The installation sequence of the ER collet is critical to ensuring the reliability and precision of clamping.

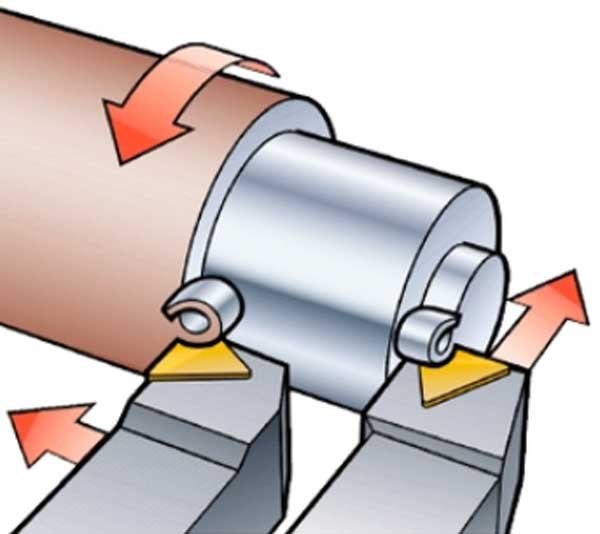

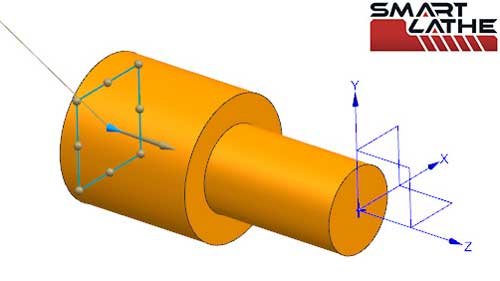

How to Properly Choose a Dual-Spindle CNC Lathe

Choosing a dual-spindle CNC lathe involves considering material specifications, processing requirements, CNC system reliability, and the manufacturer’s capacity for long-term technical support and after-sales service. If you're uncertain about which model suits your needs, you can contact SMARTLATHE's sales team. By providing your drawings and requirements, SMARTLATHE will assess the best model for you and also offer sample services and on-site equipment installation and debugging to support your manufacturing process.