How to Select Lathe Tools Use in Smartlathe CNC Lathe

The CNC lathe machine is an advance manufacturing technology that enables machine shops to create turned parts precisely and accurately. To produce high-precision parts, this machine embeds the intelligent nature of computer numerical control (CNC) technology with various lathe tools.

However, given the wide range of CNC lathe tools available, selecting the best tool for your lathe project can be difficult. A lathe tool capable of boring a part, for example, may not be suitable for threading or facing operations. Furthermore, when it comes to CNC lathe tools, you have a variety of engineering materials to choose from.

In this article, we share information on various CNC lathe tools and their suitability for different CNC lathe working. We hope it helps when you want to choose the best CNC lathe tool for your project and get it done right.

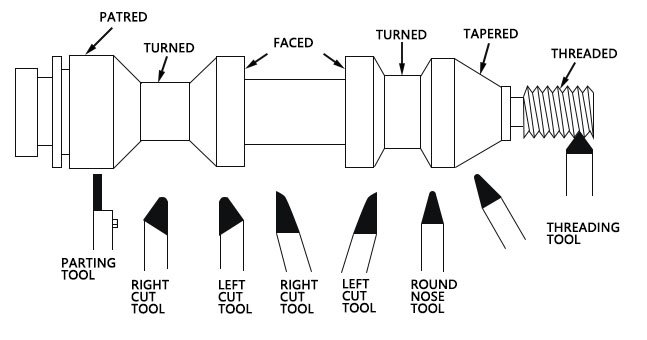

Typical Lathe Cutting Tool Operations

First, you need to know there are various lathe cutting operations you can use to achieve the desired shape, depending on the lathe machine. The following is a brief explanation of the most common operations used in your CNC turning project.

1. Facing

In most lathe operations, the first step is to face the workpiece. It entails cutting the metal from one end to fit at the correct angle of the axis.

2. Tapering

Tapering is the process of cutting metal into a cone shape with a compound slide. You can also change the angle by adjusting the compound slide, depending on your needs.

3. Parallel Turning

Cutting a material parallel to the axis is referred to as parallel turning. It is a crucial operation for reducing the diameter of the material.

4. Parting

Parting is the process of removing a part so that it faces the end. It entails the use of a parting tool. You can make the cut deeper by transferring the parting tool to the side of the cut.

Classifications of Lathe Cutting Tools

The material, end uses, and method of tool feeding are the three major classification categories for lathe cutting tools. A detailed explanation of the three different classifications and common types of cutting tools is provided below.

Classification by Material

1. High-speed steel tool

The lathe machine tool is made of high-speed steel (HSS), which can maintain hardness even at service temperatures of up to 1000° F. (588° C.). As a result, they are ideal for rough and semi-finish machining.

2. Carbide tool

The carbide tool's cutting edge is made of carbide. As a result, they're great for cutting iron, plastic, glass, stone, steel, and other tough materials.

3. Diamond Blade

Diamond is a material that is extremely hard and resistant to wear. It has a low coefficient of friction, a high elastic modulus, a high thermal conductivity, and a low coefficient of thermal expansion. As a result, diamond-cut lathe tools are ideal for precision machining of brittle, wear-resistant, conforming, and hard materials such as graphite.

4. Other Materials

Like cubic boron nitride and ceramic, provide the cutting edge for these types of machine lathe tools. As a result, they are ideal for rough machining and hard alloy cutting.

Classification of Lathe Cutting Tools by Use

1. Turning Tool

In terms of application, there are two types of turning cutting tools: rough turning tools and finish turning tools.

Rough turning tools

Rough turning tools are used to quickly remove large parts of a workpiece. They have a ground cutting angle for removal and can withstand maximum cutting pressure.

Finish turning tools

Finish turning tools are lathe machine tools that are used to remove small parts of the workpiece. The angle is ground, and as the name implies, the finished product has a smooth and accurate surface.

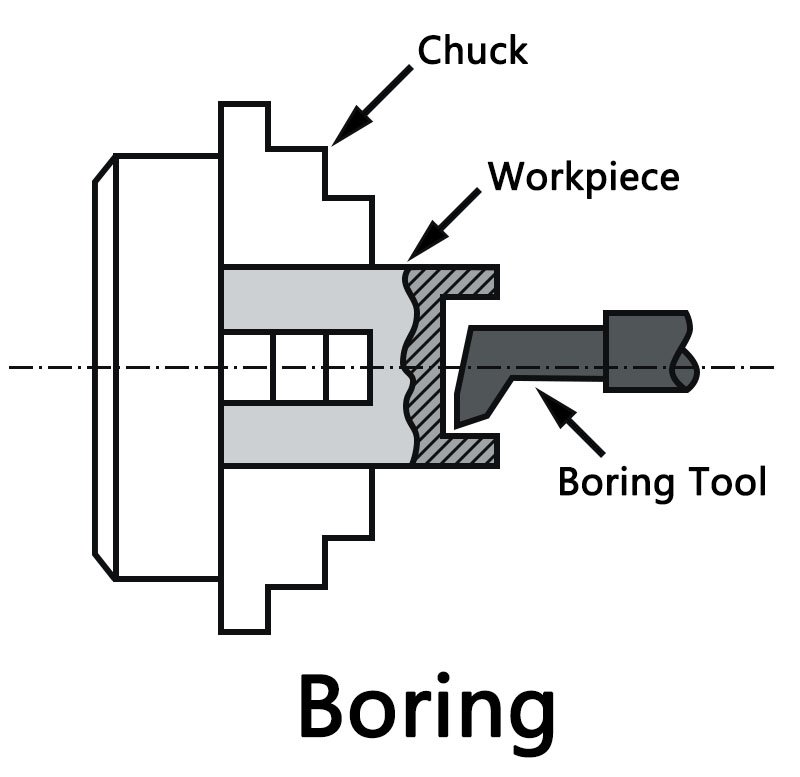

2. Boring Tool

A boring tool is a type of lathe tool that is used to enlarge a hole. These turning cutting tools are inserted into pre-existing holes and used to increase the diameter of the holes.

3. Chamfering Tool

Chamfering tools are lathe turning cutting tools that are used to create a furrow on a part. It can also be used to smooth or dangerously edge a workpiece.

4. Knurling Tool

Knurling tools are lathe tools that can produce knurled lathe parts by forming a specific pattern into a round section. As a result, you can use them as a grip for handles or fasteners such as nuts.

5. Parting Tool

A parting tool is a narrow-bladed tool used to cut material off of a workpiece. It comes in a variety of shapes and sizes, and its most common application is as a turning and cutting tool.

6. Thread Cutting Tool

Thread cutting tools can be used to cut threads on a lathe part. Internal and external thread cutting are the two most common types. External thread cutting involves holding the workpiece in a chuck or mounting it between two centers. Internal thread cutting, on the other hand, involves holding the part in a chuck while the tool moves across it in a linear fashion, taking chips off the workpiece as it passes.

7. Facing Tool

A facing tool is a type of lathe machine tool used to cut a flat surface perpendicular to the rotational axis of a workpiece. The tool holder on the lathe carriage holds the tool during the process, allowing it to feed perpendicularly across the part's rotational axis.

Classification of Lathe Cutting Tools by Method of Applying Feed

1. Right-Hand Tools

When moving from right to left, a right-hand tool removes material. The term "right-hand tool" was inspired by the human hand. The tool feed direction is represented by the thumb on the right human hand. As a result, the tool's primary cutting edge is on the tool's left side.

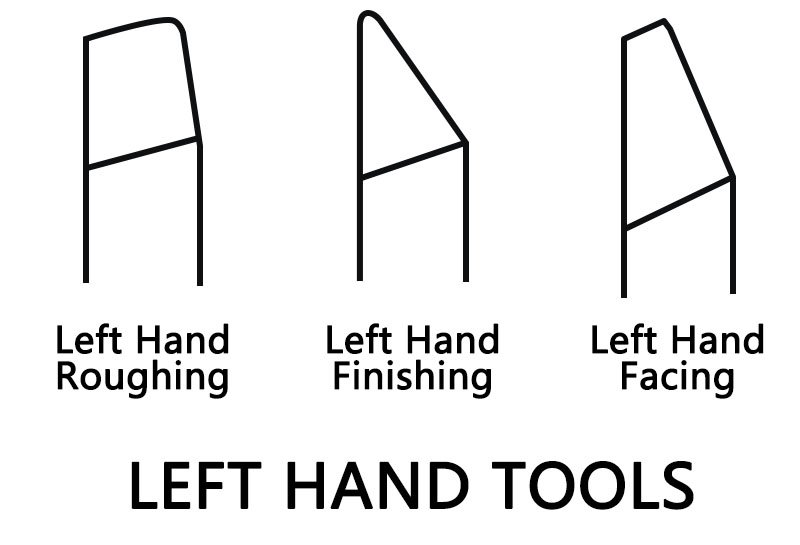

2. Left-Hand Tools

The left-hand cutting tool, unlike the right-hand tool, removes material when moved from left to right. The tool feed direction is represented by the thumb on the left human hand. As a result, the tool's primary cutting edge is on its right side.

3. Round Nose Tools

There is no back or side rake on a round-nose turning tool. As a result, the tool is fed from the left to the right or from the right to the left end of the lathe bed. However, the round nose tool may have a small back rake in some cases. Round nose turning tools are popular in finish turning operations due to their round edge.

Now You Should Know How to Select Lathe Machine Tools?

All in all, lathe cutting tools are an essential component of any CNC machining or turning operation. To summarize the above, you could consider the factors including the type of materials, the shape of the tool, and the desired shape to work with Smartlathe CNC lathes to fulfill the best potential of the CNC turning jobs.

FAQs

1. What are cutting tools used for?

Cutting tools, also known as cutters, are used to remove pieces of a workpiece. They are mounted on a lathe, a machine that turns materials and shapes them to the desired shapes. Cutting tools include boring tools, chamfering tools, and so on.

2. What are the types of lathes cutting tools?

Type 1: Turning Tool

Type 2: Boring tool

Type 3: Facing tool

Type 4: Chamfering Tool

Type 5: Knurling Tool

Type 6: Parting Tool