The Benefit of Collect Chuck VS 3- Jaw Chuck

Most CNC lathe users use three-jaw chucks as their standard work-holding equipment. It is one of the most commonly utilized chuck types in a variety of turning applications. That does not, however, imply that it is the ideal chuck for all jobs. A collet chuck is a work-holding device that also relies on mechanical forces to keep a workpiece in place. While a collet chuck cannot accept the same wide variety of workpiece sizes as a jaw chuck, it does provide advantages in speed, precision, and productivity that are important for some operations.

What is a Collet Chuck?

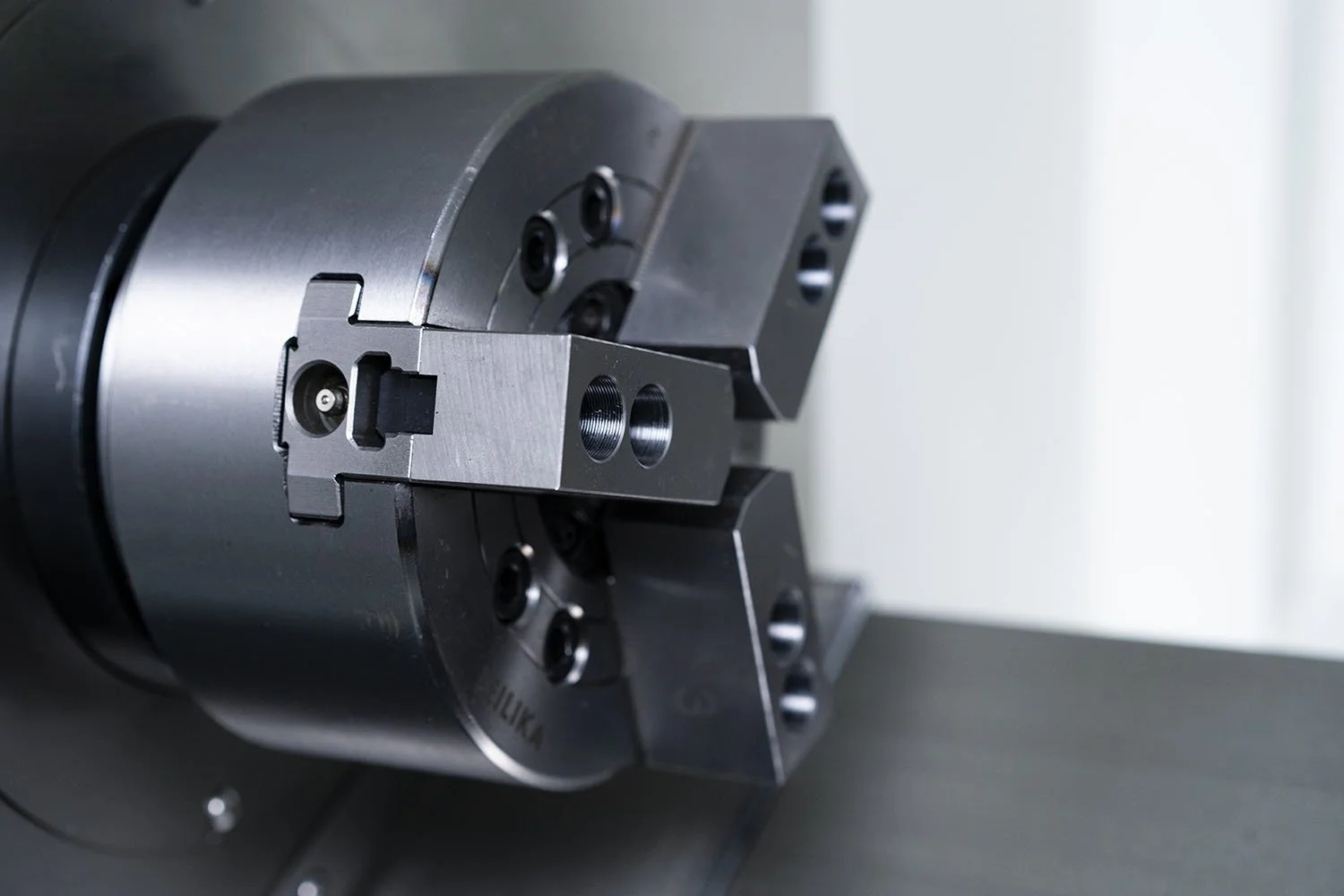

A three-jaw power chuck, a hydraulic actuation cylinder, and a drawtube comprise the typical work-holding system included with most CNC lathes and turning centers. The hydraulic cylinder is joined to the spindle's back end, while the chuck is attached to the front or working side. A hollow steel drawtube that runs through the spindle bore is commonly used to connect the cylinder and chuck.

A CNC collet chuck is mounted to the front of a CNC lathe spindle, using the machine’s existing collet and drawtube to move the workpiece.

The jaws of the collet chuck open and close due to the axial motion of the hydraulic actuator's piston. As the piston travels back and forth, the drawtube moves in lockstep with the piston, forcing a wedge-shaped plunger within the chuck body. The plunger, in turn, transfers axial action into radial motion, allowing the jaws to open and close. The jaws' gripping force on a workpiece is proportional to the actuator's output, therefore it may be readily controlled with a pressure valve.

A collet chuck, of course, needs a collet to work. Collets typically have a gripping range of about 0.062". Collets for round, hex, and square stock are widely accessible. A collet chuck may accommodate a wide variety of collets (from 3/16" to 2-5/8"). Special collet specifications can be met. For faster set-up times, most current collet chucks have a quick (e.g., 10 seconds) change feature.

How To Select to Use 3-Jaw Chuck and Collet Chuck?

The benefits and drawbacks of each type of chuck must be weighed against your application's lot sizes, material diameter range, material types, workpiece lengths, and dimensional tolerances, among other factors. Consider the following information:

Versatility. 3-jaw chucks are a good choice if you're doing a lot of different projects with varied workpiece diameters. Collet chucks are ideally suited for workpieces with a diameter of 3" or less. Because the longer collet chuck limits Z-axis travel, 3-jaw chucks are also more suited for cutting longer workpieces.

Spindle performance. Collet chucks have less bulk than other chucks, thus the lathe spindle gets up to speed faster and exerts less pressure on the spindle motor. Furthermore, the lighter collet chuck allows for heavier workpiece handling at greater spindle RPMs.