The right machine for you is just around the corner.

Send us your needs and drawings, we have a professional team to develop a suitable solution for you with an affordable prices.

What Happens to Your Drawing?

1. Drawing Analysis

Once we receive your drawing, our team gets to work. If it’s a 2D file, we’ll first build a 3D model to better visualize the part and prepare for programming. This step helps us spot any potential manufacturing issues early and ensures everything flows smoothly later.

2. Simulation Programming

We use software like UG-NX, MasterCAM, Fusion 360, or SolidCAM—depending on what you’re used to. Our goal is to make sure the program not only runs correctly, but also fits your style and expectations. We run full simulations before moving to the next step.

3. Process Report & Machine Recommendation

You’ll receive a clear report explaining how we plan to machine the part, along with our recommended Smartlathe model. This helps you understand the process, estimate time and cost, and make informed decisions for production.

Click to preview report —>

Not Enough?

More benefits are waiting for you.

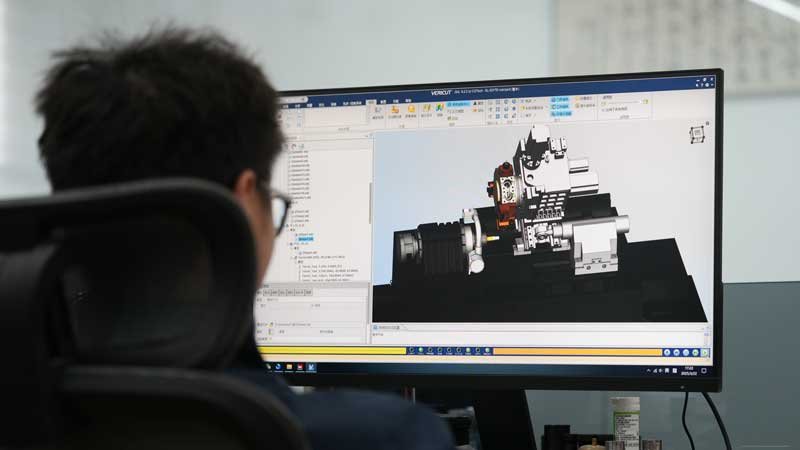

EX.1 VERICUT Simulation

For added peace of mind, we offer VERICUT simulation. We load your program into the digital twin of the recommended machine to check for collisions, over-travel, and any hidden risks before real machining begins.

EX.2 On-Machine Trial

We set up the actual Smartlathe machine, get the right materials and tools, and perform a real-world machining test. This gives you a solid preview of how the part will turn out in actual production.

EX.3 Sample Measurement Report

After machining, we measure the sample using precision instruments and provide a detailed inspection report. This helps confirm that the part meets your requirements before going into mass production.

EX.4 Sample Delivery

Finally, we pack up the sample and ship it straight to you. That way, you can check the real product in hand, test fit or function, and give the final green light with confidence.

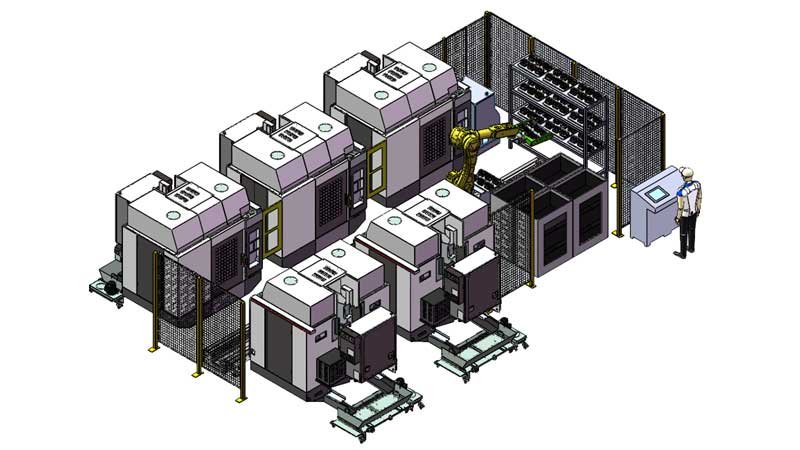

EX.5 Workshop Layout Planning

If you’re considering adding or upgrading machines, we can help you plan your shop layout. We’ll suggest a practical arrangement for equipment, materials, and workflow to help improve efficiency, safety, and long-term scalability.