Yasin Bhatti

Transitioning to CNC with SmartLathe for Streamlined Production

Yasin Bhatti, an industrial fasteners expert from the UK, discovered SmartLathe through our online presence, including detailed product information and machining videos. Yasin has an in-depth understanding of fastener production processes and works for a well-established company that has been providing high-quality industrial fasteners to the UK and parts of Europe for over 30 years. However, they were using older machines that required parts to be processed on multiple machines, which resulted in inefficiencies and higher labor costs.

The Challenge: Streamlining Production

Yasin’s primary goal was to find a CNC lathe that could streamline production by performing multiple tasks on a single machine, saving both time and labor costs. After researching various options, he reached out to SmartLathe and provided us with part drawings and specific requirements. Our team carefully analyzed the drawings and offered a comprehensive machine proposal tailored to his needs.

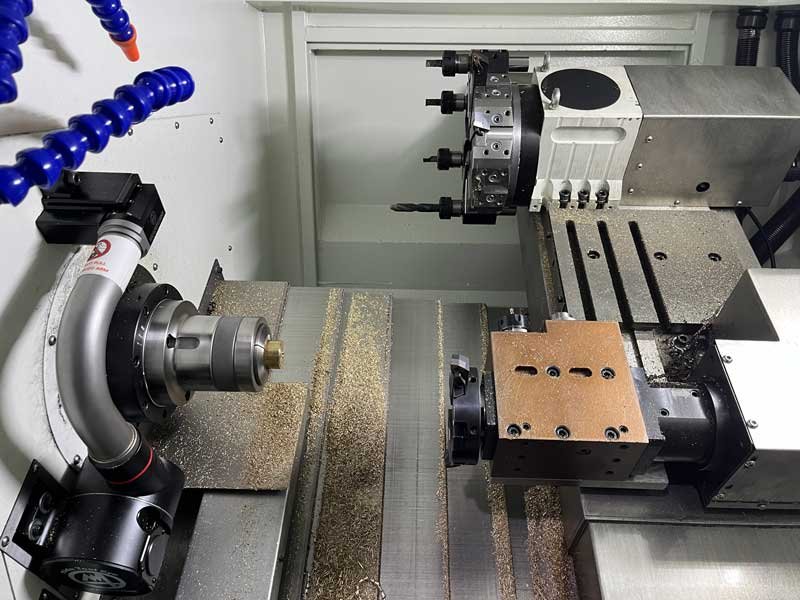

The Solution: SL-X with Polygon Turning

After reviewing the options, Yasin selected a multi-functional configuration: the SL-X CNC Lathe with Polygon Turning, Milling Device, Servo Turret, and Automatic Tool Setter. This configuration provided:

Polygon Turning Function for complex shapes,

Milling Function to handle milling tasks in addition to turning,

8-position Servo Turret for sufficient tool stations to manage multiple operations efficiently, and

Automatic Tool Setter to save setup time by automating tool offsets.

The SL-X was a compact and versatile solution, ideal for small-batch production, perfectly fitting Yasin's workshop without occupying unnecessary space.

The First-Time CNC Buyer

This was Yasin’s first time purchasing a CNC lathe from China and his first experience using CNC technology. He took every step seriously, from inquiring about factory electrical configurations to seeking detailed information about the machine’s capabilities. Our team patiently provided professional, thorough answers to his questions. After careful consideration, Yasin placed the order, and we began the production process.

Factory Visit: Training and Experience

Yasin decided to visit our factory in China. We arranged for him to inspect the machine, receive hands-on training, and see the machine in action before it was shipped.

To help facilitate his travel, we provided an invitation letter, enabling him to secure the necessary visa.

During his visit, Yasin also took advantage of our Sample Demo Service, where we set up the required programs and tools on the machine according to his part drawings and specifications, and produced the sample part. This allowed him to fully understand the machine’s capabilities and gain confidence in its use.

A New Perspective: Yasin’s Experience in China

This was Yasin’s first trip to China, and before arriving, many of his friends were skeptical about purchasing Chinese-made equipment. However, after visiting China and experiencing the country's economic growth and industrial capabilities firsthand, Yasin completely shifted his perspective. He was impressed by China’s development and the quality of the equipment we provided.

Yasin’s time in China not only helped him gain a deeper understanding of SmartLathe's technology but also redefined his perception of Chinese manufacturing.

Post-Training: A Smooth Installation and Ongoing Support

After completing a week of hands-on training at our factory, Yasin was fully prepared to operate the SL-X back in the UK. Upon his return, our reliable logistics partners ensured the safe delivery of the machine to his facility.

Once the machine arrived, our after-sales team was there to provide online guidance, helping Yasin with installation and troubleshooting. During the initial stages, Yasin contacted us frequently, and we answered all his questions to ensure he was up and running smoothly.

As Yasin became more familiar with the machine, he started optimizing the production process and improving efficiency.

One Year Later: Successful Production and Future Plans

One year later, the SL-X had successfully helped Yasin produce a wide range of high-quality fasteners, streamlining his production and increasing efficiency. He has seen significant cost savings and a substantial return on investment.

Recently, Yasin expressed interest in upgrading the Polygon Turning tool on his SL-X. We are currently preparing a full upgrade package and will provide installation and training to ensure continued production optimization.

Yasin is also planning to visit our factory again and is considering purchasing a higher-performance CNC lathe to further expand his production capacity.

🛠️ SmartLathe: Your Partner in Precision Machining

At SmartLathe, we don’t just provide equipment — we provide solutions that help your business thrive. Whether you're a first-time CNC buyer or an experienced manufacturer, we’re here to help you optimize your operations and boost your productivity.

📩 Ready to start your journey?

Contact us today to discuss how SmartLathe can help streamline your production.