Dual Spindle CNC Lathe

DS-25F

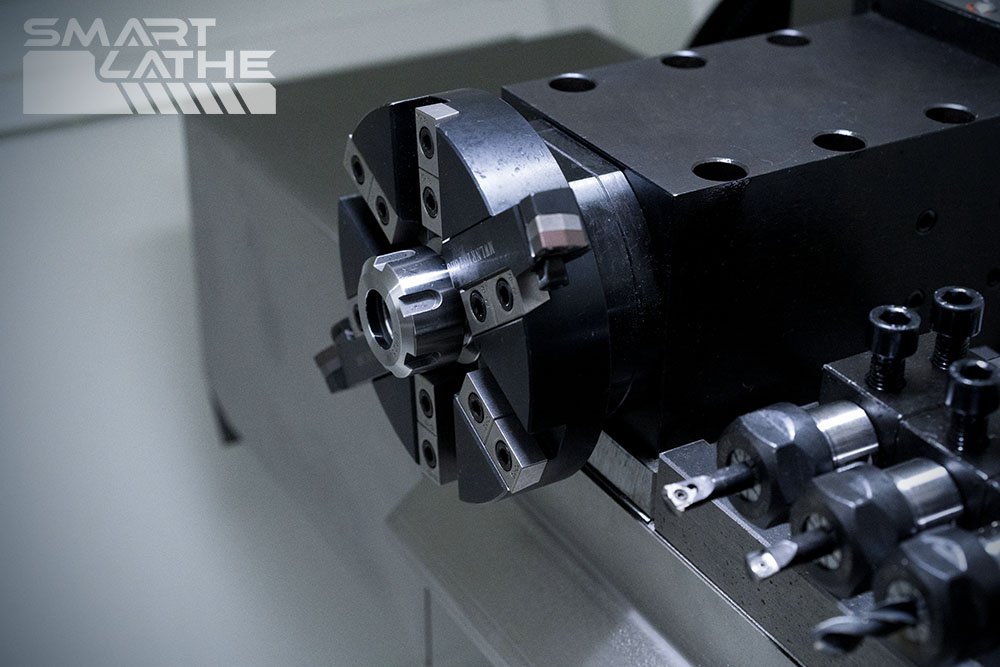

An upgraded version of the SL series with dual spindle gang type CNC lathe. The most cost-effective solution for the parts turning in one setup. Especially born for the parts like adaptors, male & female connectors, pipe connectors, etc.

| Techical Data | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Features | ||||||

|

||||||

| Optional | ||||||

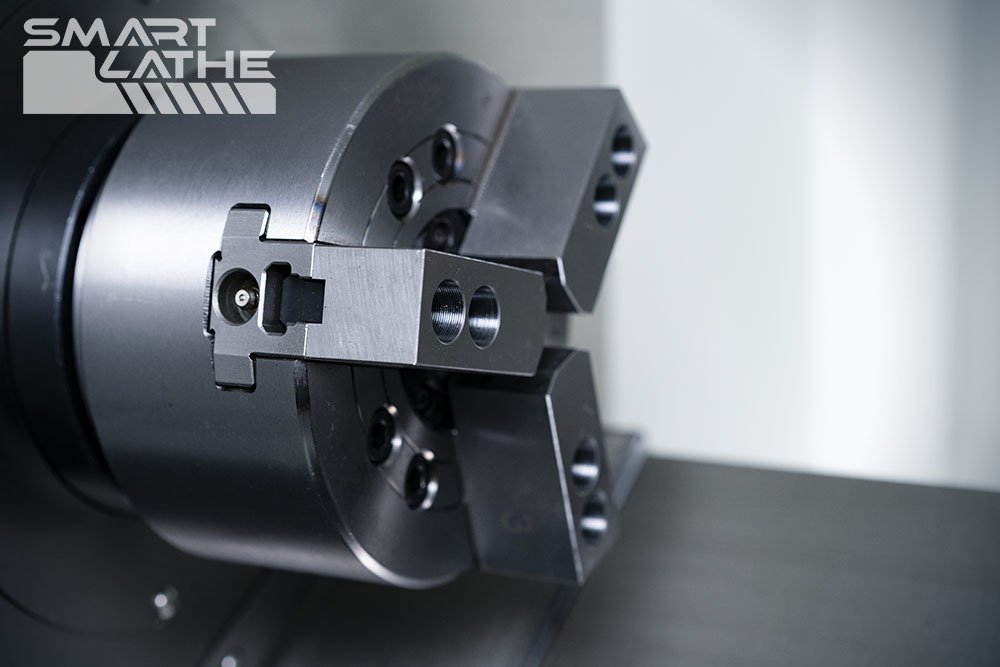

3 Jaws Chuck

Live Tool Device

Polygon Turning |

||||||

Application

Competent to handle the turning process with brass, bronze, aluminum, steel, stainless steel, and rigid plastic with single workpieces up to φ25mm. High Rigidity casting iron body provides the possibility of higher hardness materials and better smoothness (smaller roughness).

Case Study

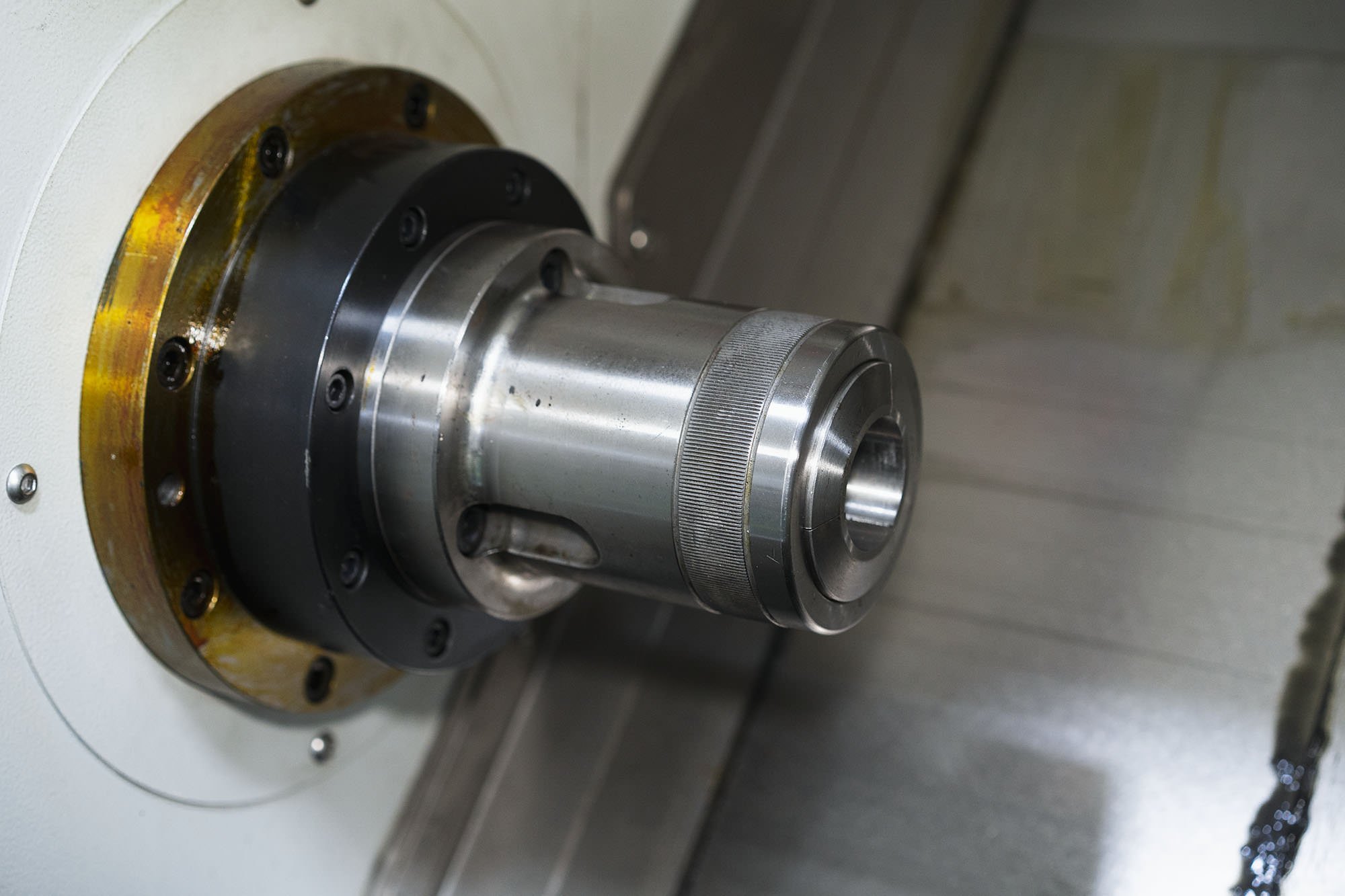

Configuration: DS-25F installs the Hydraulic collect, Automatic loading,

Gang type tools.

Workpiece: Individual custom brass castings.

Machining Process: Turning, Facing, Drilling, Threading.

Turning Duration: within 45 seconds one-time processing.