Dual Spindle CNC Lathe

DS-36S

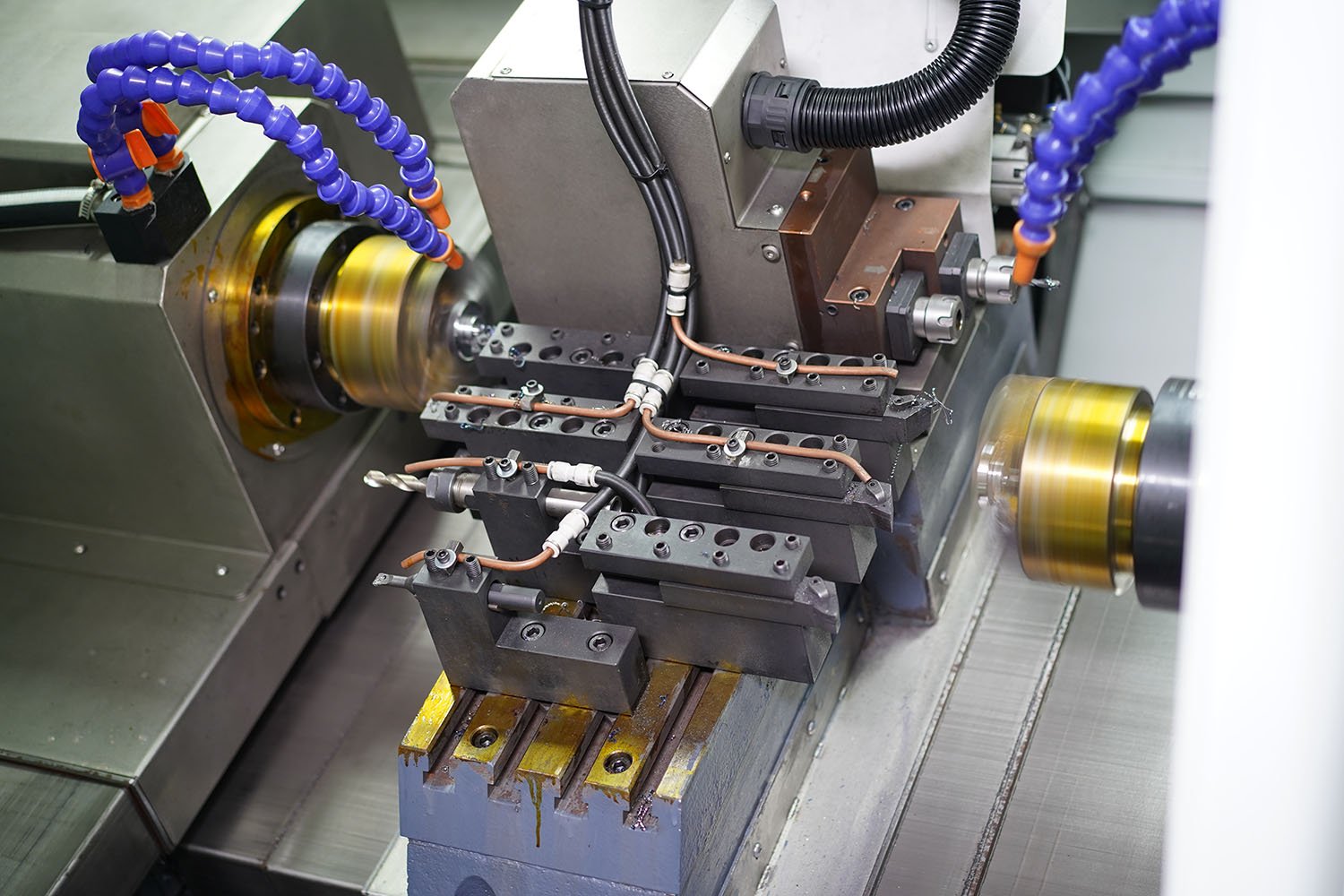

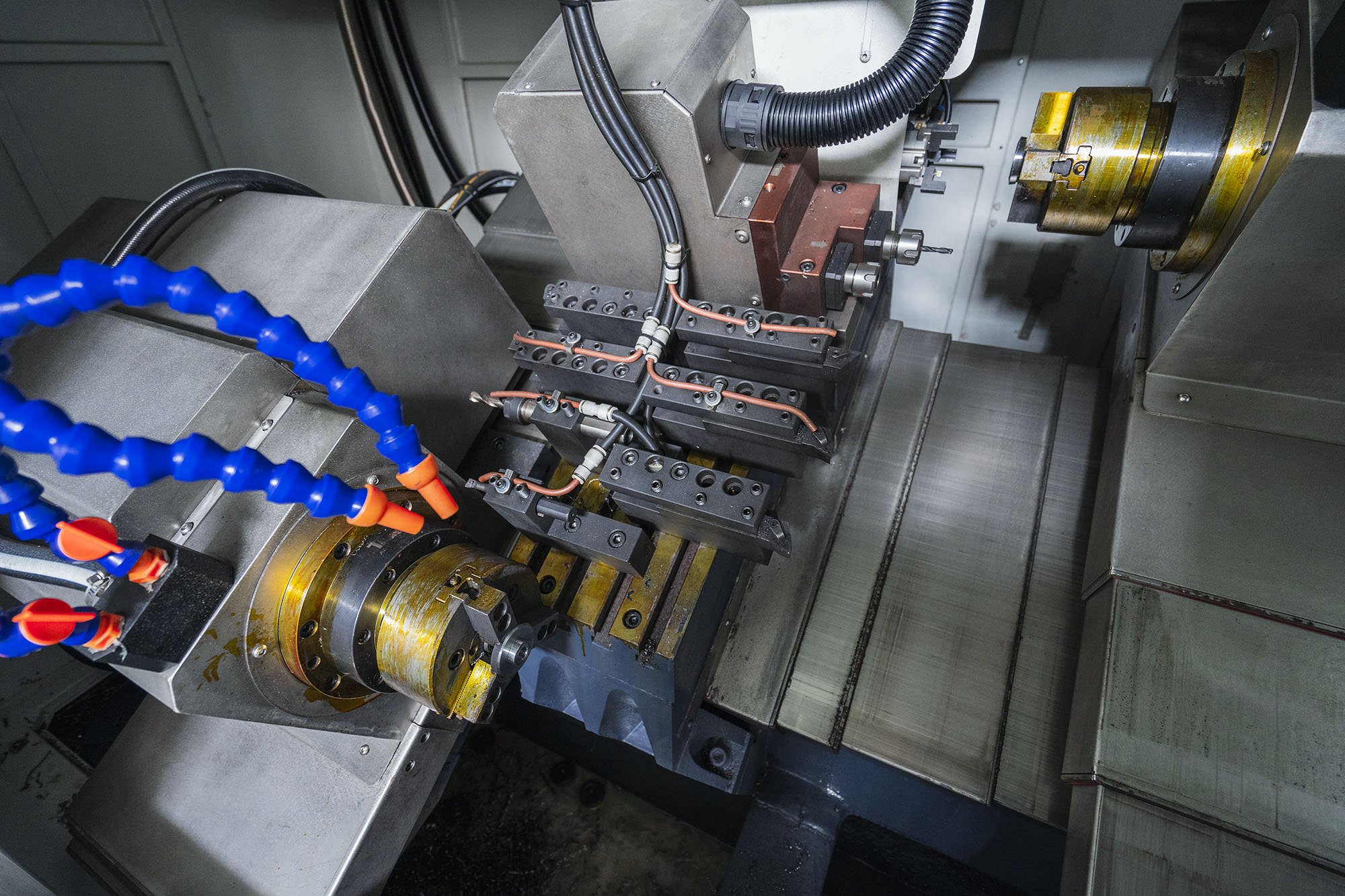

Innovative design for an Integrated with two single-spindle CNC lathes in one machine tool which could achieve double efficiency thanks to the two independent channels for synchronous machining. Besides, Double-ended parts can be turned by DS-36S dual-spindle lathe with the twin spindles. The 30-degree slant bed design contributes to faster chip removal and running speed.

| Techical Data | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Features | ||||||

|

||||||

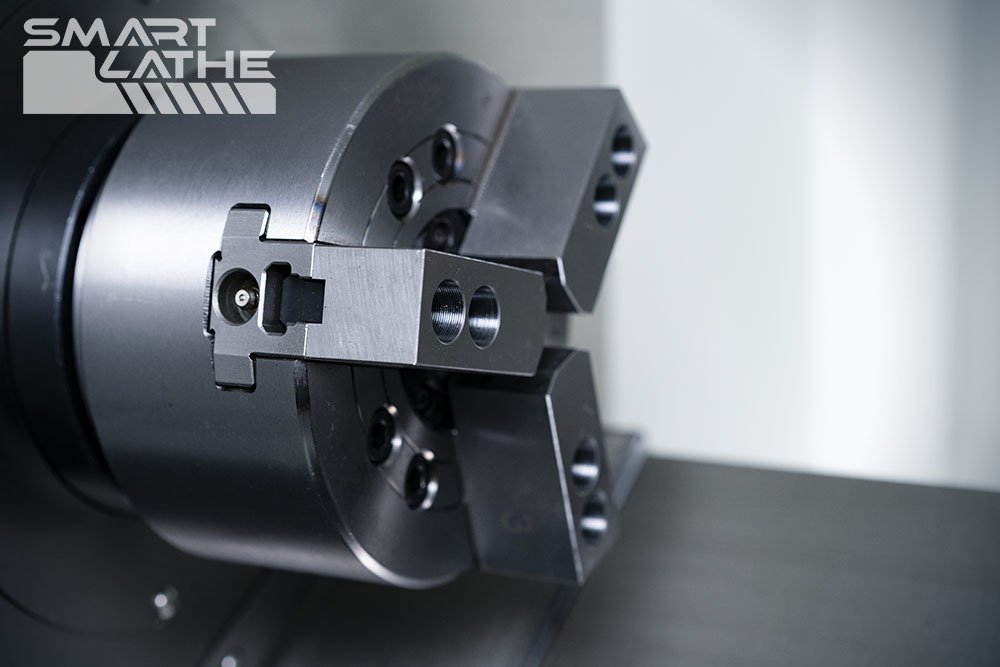

| Optional | ||||||

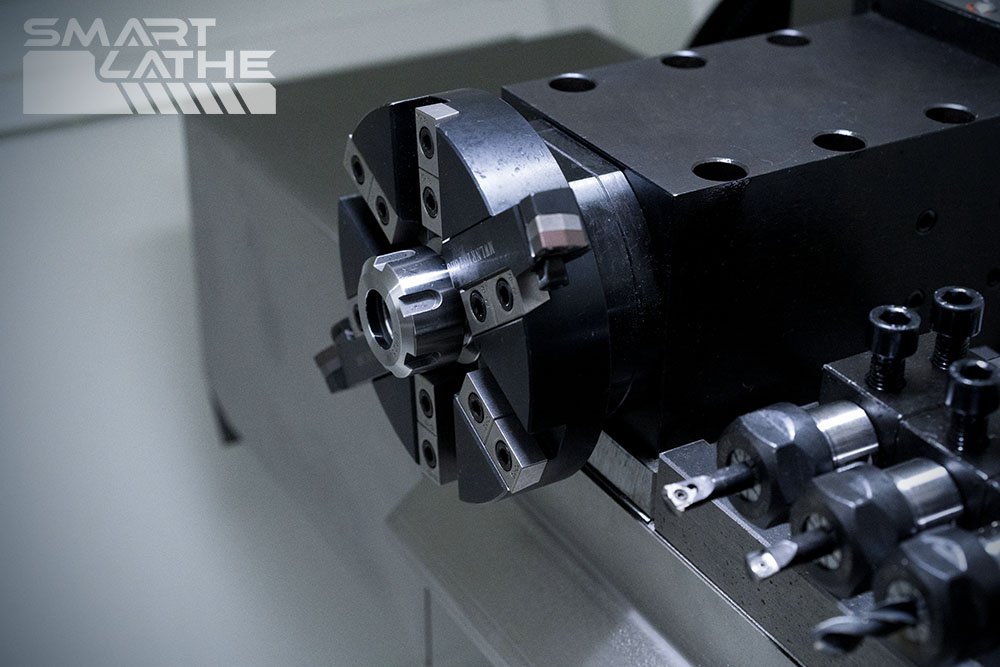

3 Jaws Chuck

Live Tool Device

Polygon Turning |

||||||

Application

Suitable for the metal workshops’ pursuit of high efficiency and high accuracy turning. DS-36S is capable of handling the turning process with brass, bronze, aluminum, steel, stainless steel, and rigid plastic with single workpieces up to φ36 mm. The automatic devices could be tailored to the client’s production requirements.

Case Study

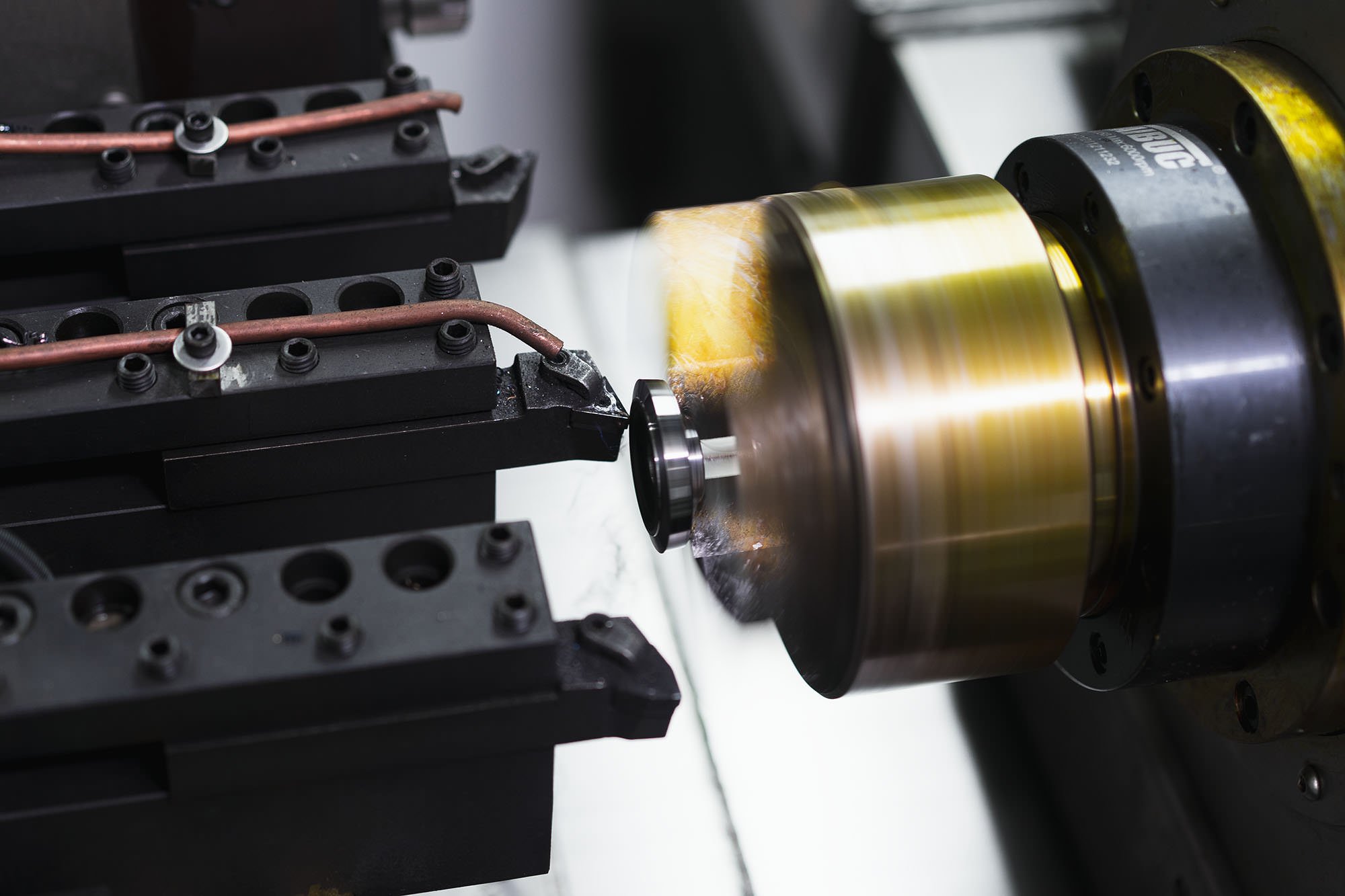

DS-36S Configuration

Configuration: DS-36S installs the 3-Jaw Hydraulic Chuck, Gang type tools, Live Tool Device, Automatic loading & unloading

Workpiece: Power Tool Components

Machining Process: Turning, Facing, Drilling, Chamfering.

Turning Duration: within 90 seconds of one-time processing