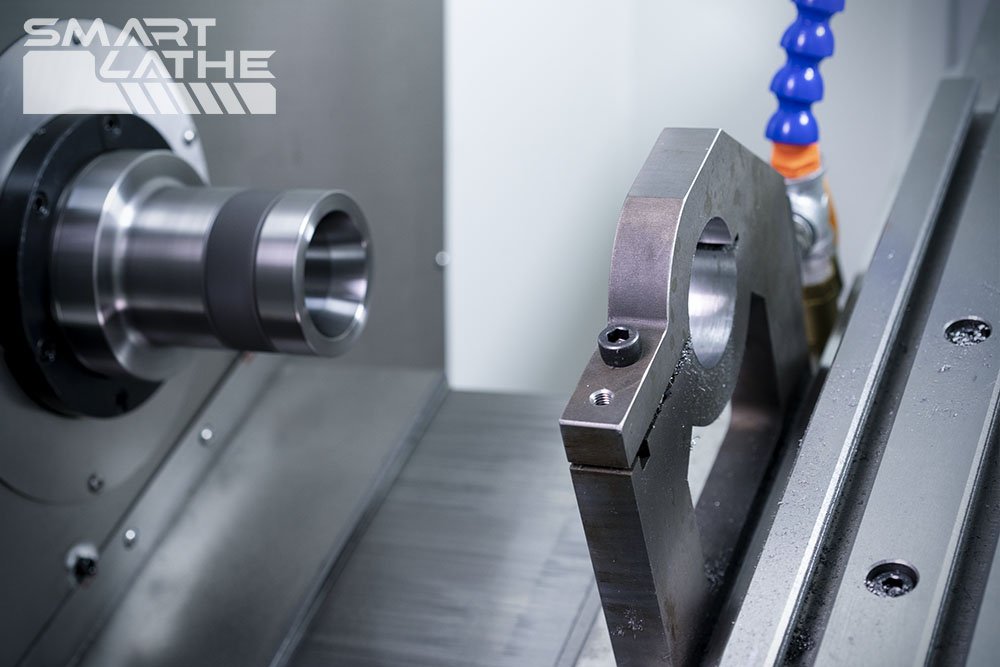

Smart CNC Lathe

SL-07

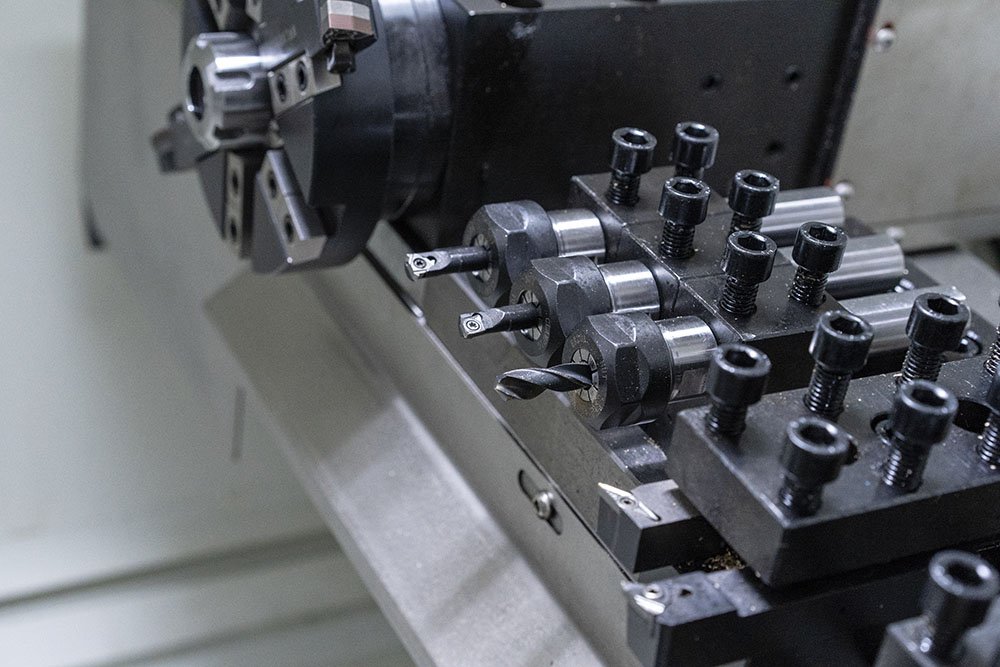

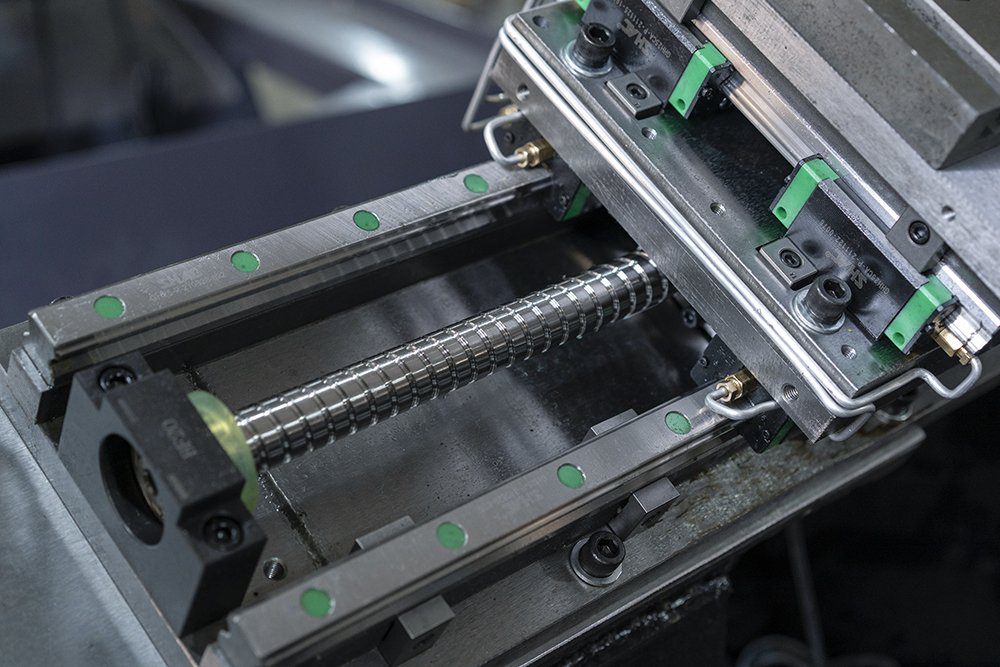

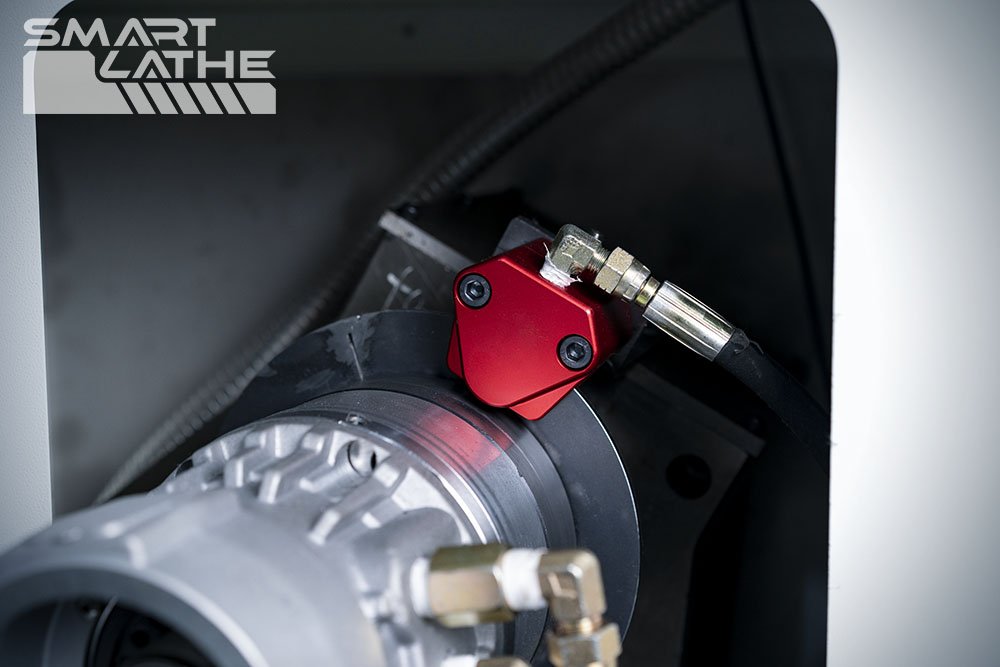

SL-07 with gang-type tool changers perfect fits for the prototyping of smaller workpieces. Fast tool-changing and slant bed construction guarantees increased productivity and easy chip removal. The pneumatic collet with through-hole enables fast loading and the possibility of continuous feeding.

| Techical Data | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Features | ||||||

|

||||||

| Optional | ||||||

Spindle Brake

Auto Bar Feeder

Fixed Guide Bush |

||||||

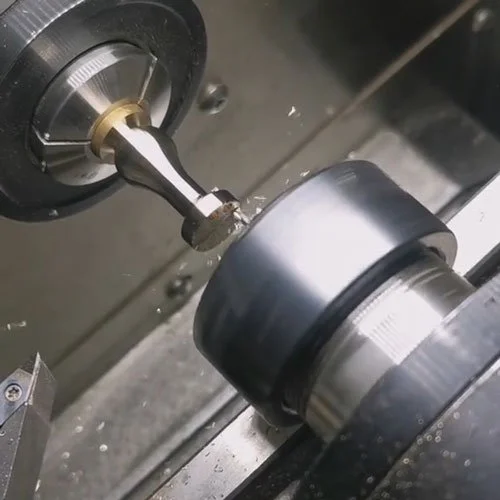

Application

Competent to handle the turning process with brass, bronze, aluminum, steel, stainless steel, and rigid plastic with bars diameter up to 7 mm or single workpieces diameter up to 200mm (Chuck size up to 25mm).