Smart CNC Lathe

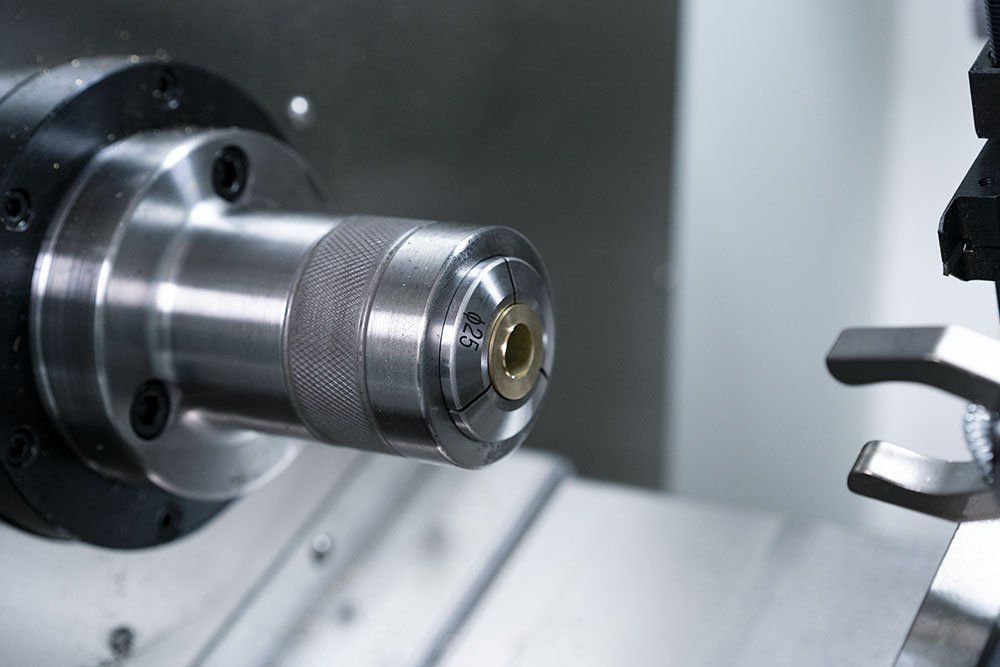

SL-25

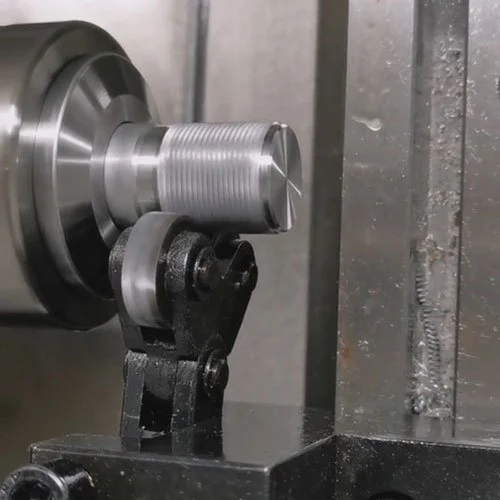

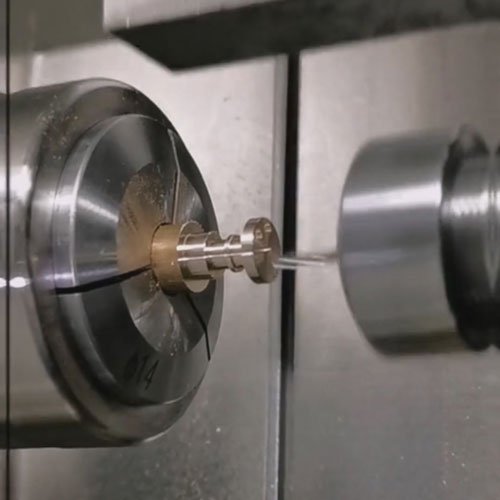

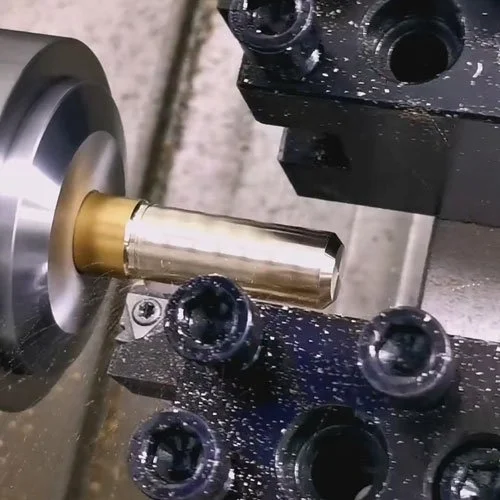

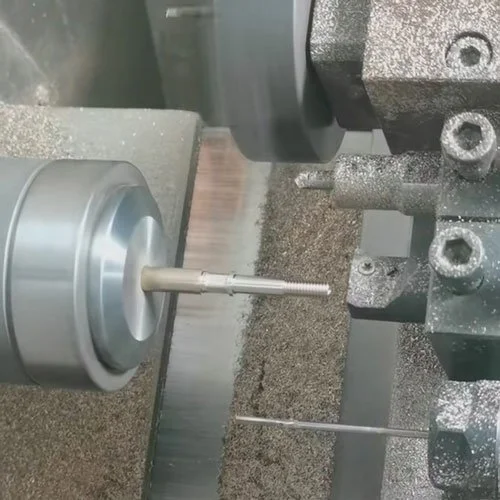

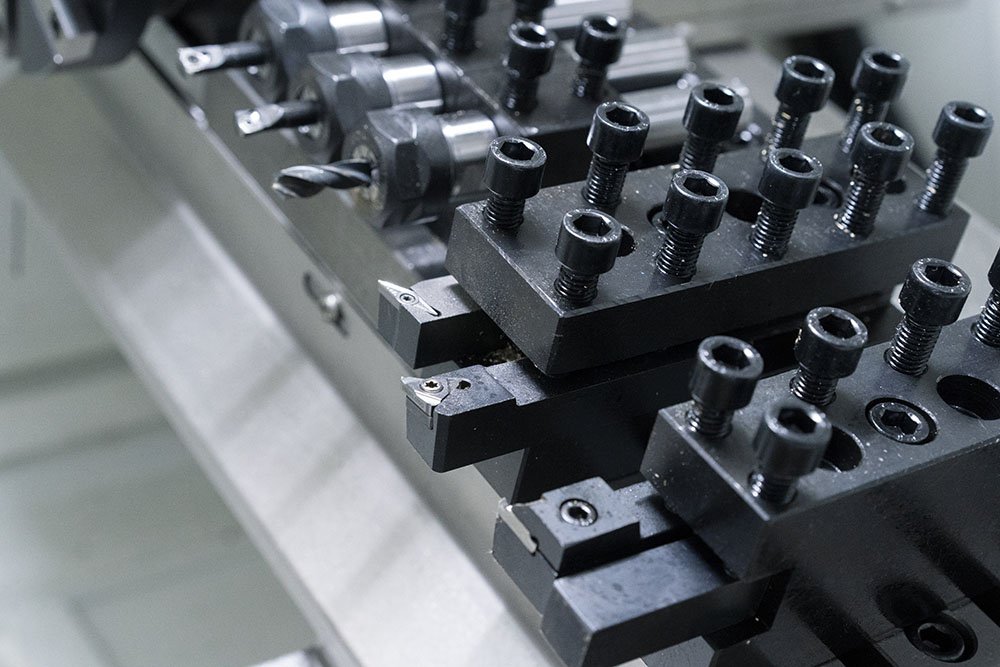

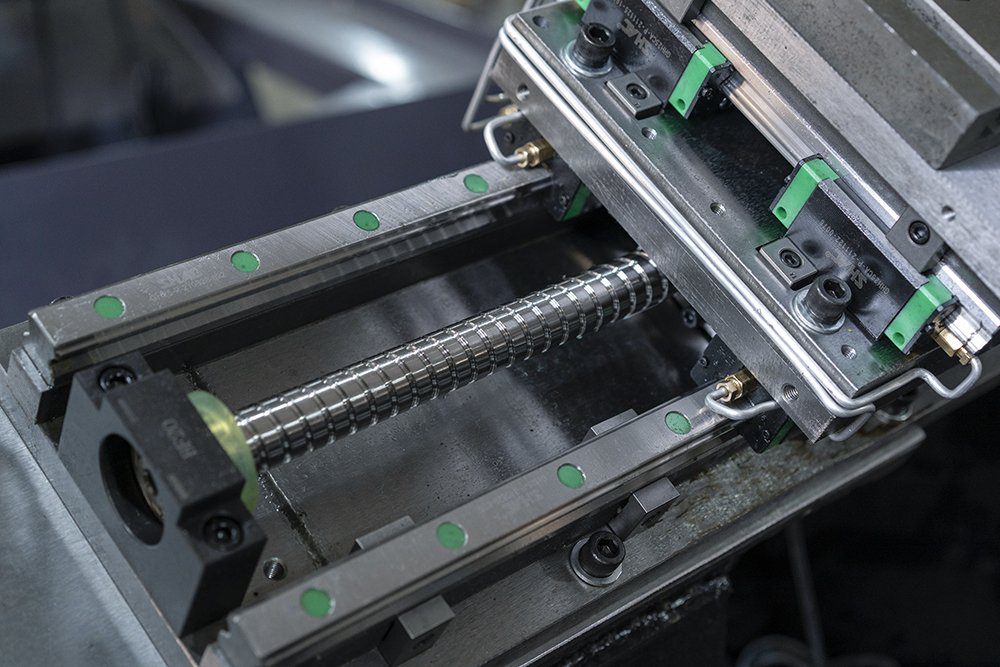

The model of the SL-25 is equipped with a larger travel span of the X and Z-axis plus the robust and precise hardened linear guides providing a capacious work envelope for the various tool arrangements, like the possibility of side live tooling on the X-axis. Thanks to the self-developed SmartBrian™ CNC control system, programming with CNC simulation is quite user-friendly.

| Techical Data | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Features | ||||||

|

||||||

| Optional | ||||||

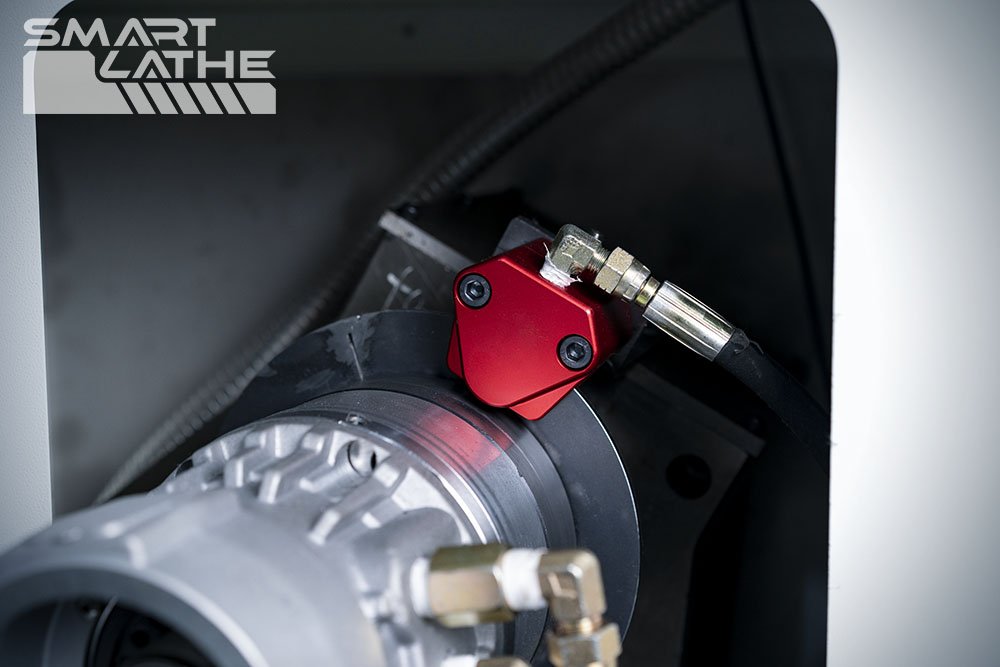

Spindle Brake

Auto Bar Feeder

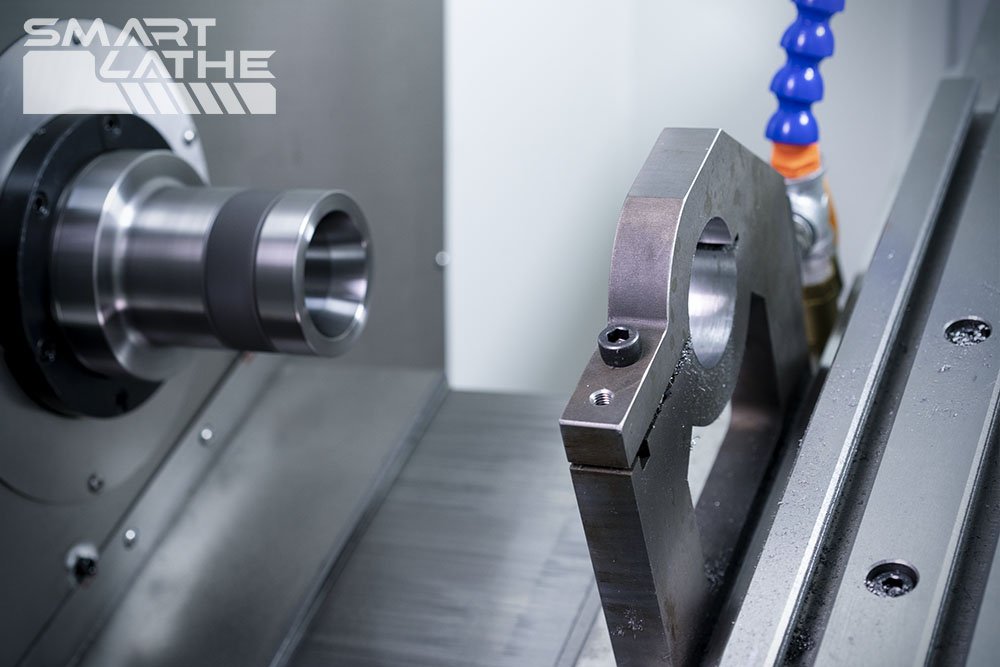

Fixed Guide Bush

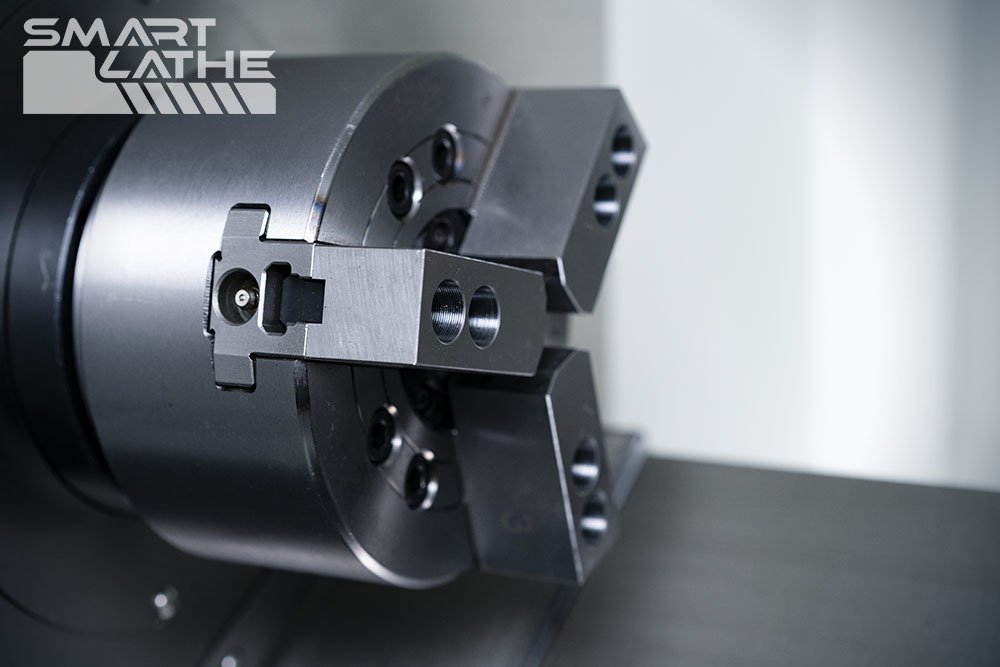

3-Jaws Chuck

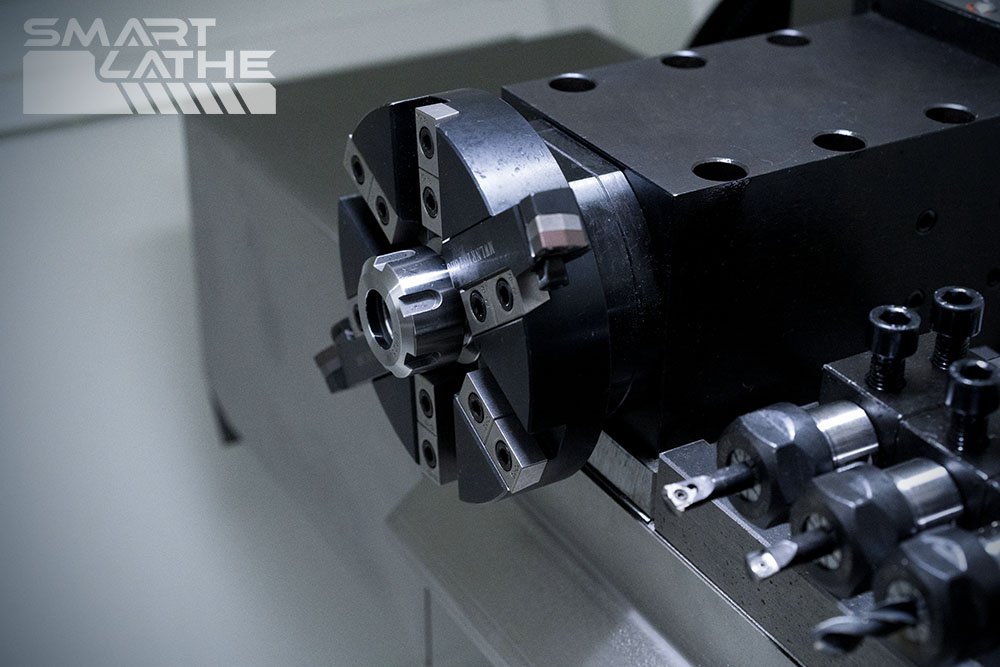

Step Type Live Tool

Polygon Milling |

||||||

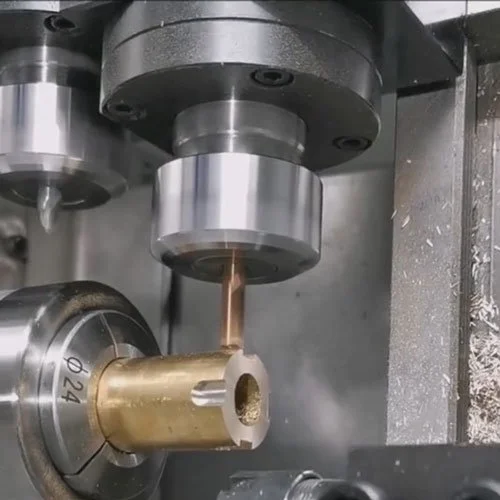

Application

The best choice of series & mass production of washers, bolts, shafts, rivets, spacers, sleeves, nipples, stainless steel fittings, pipe fittings, light fittings, wheel studs, etc. with copper, aluminum, steel, stainless steel, and rigid plastic, etc. with bars diameter max. Φ25 mm or individual workpieces diameter max. φ350mm (Chuck size max. Φ40mm).