Smart CNC Lathe

SL-36

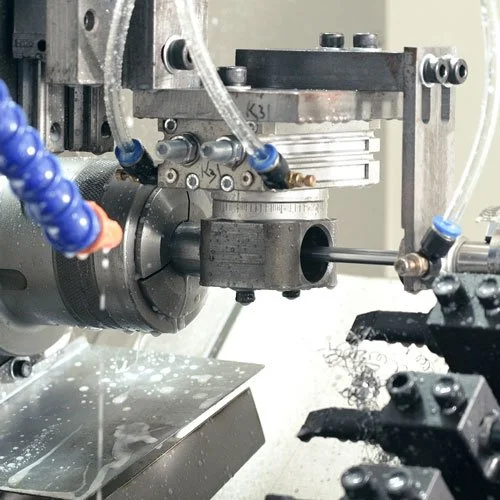

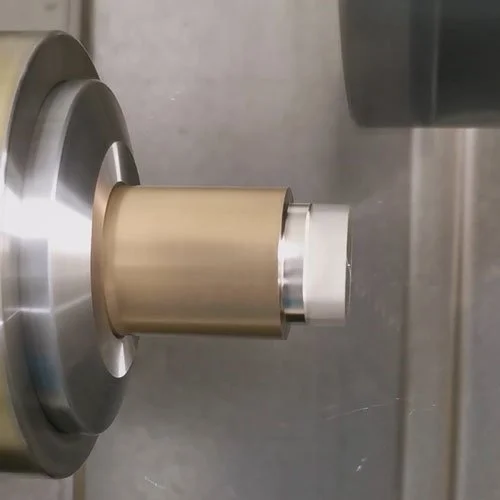

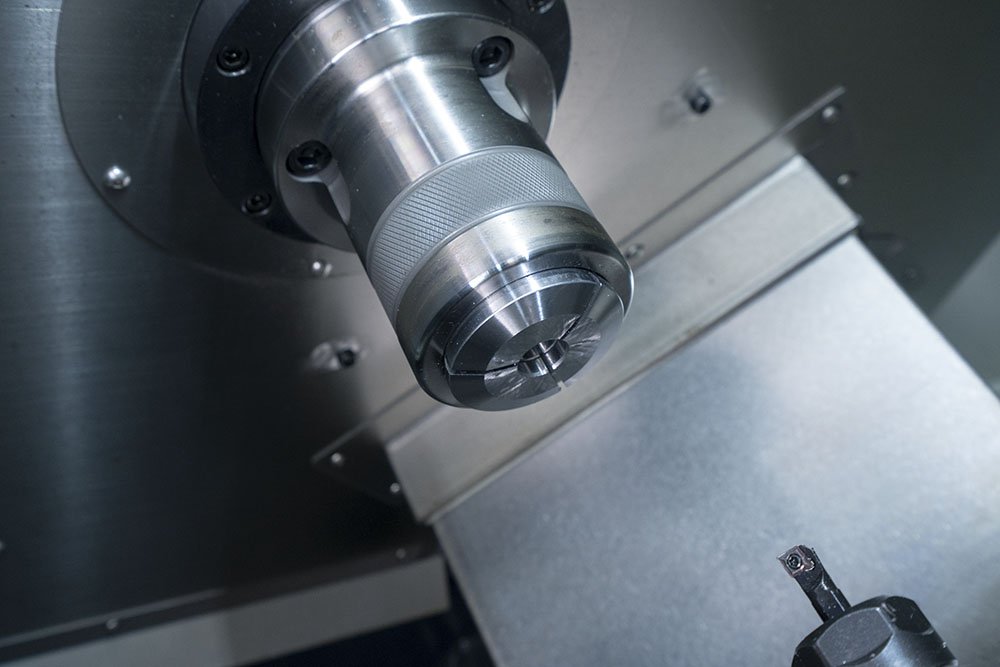

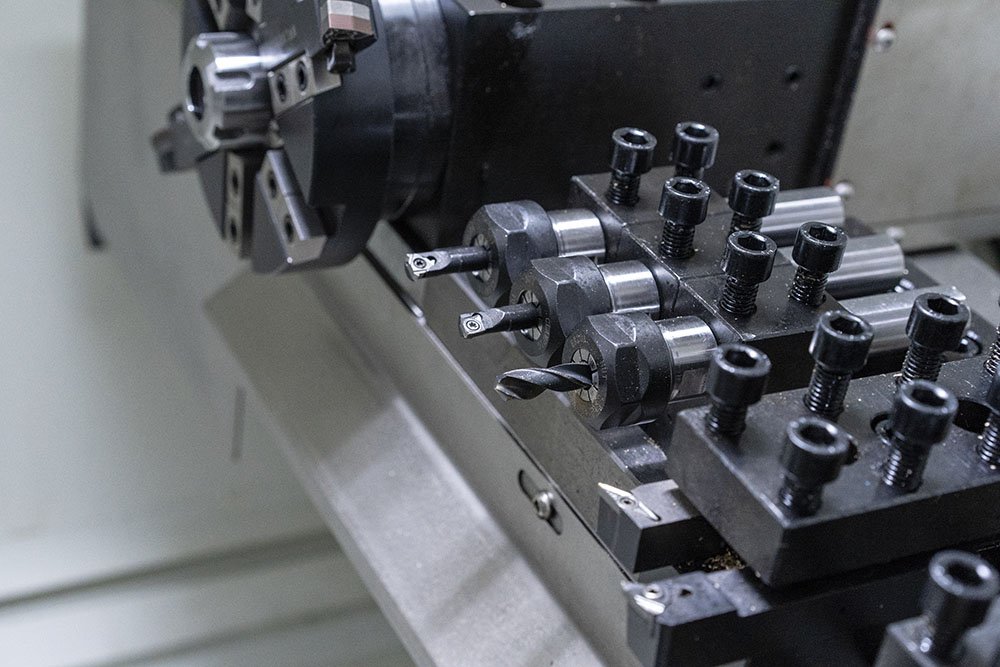

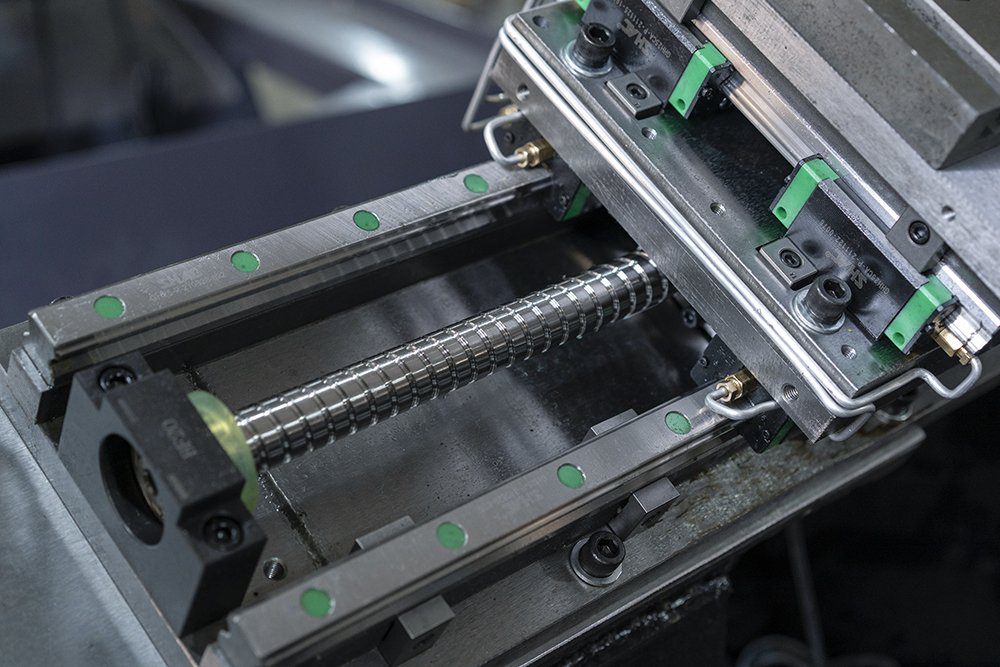

SL-36 comes with a high-speed spindle with 4,000 RPM, providing 4-HP powerful output for heavy-duty machining. Thanks to a large work envelope with extensive X/Z travel, it could configure with a wide variety of tools, like side live tooling devices, Y-axis for grooving, drilling, and radial cuts on the OD. Multi-positions turret, polygon milling device for knurling, threading, and face milling on the end surface.

| Techical Data | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Features | ||||||

|

||||||

| Optional | ||||||

Servo Bar Feeder

Oil Bar Feeder

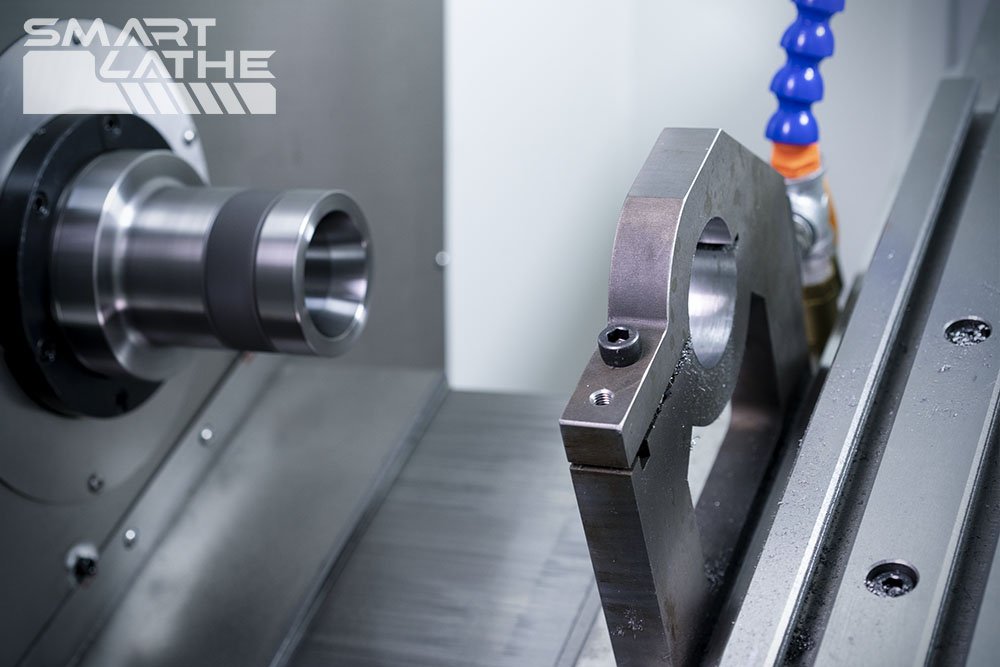

Fixed Guide Bush

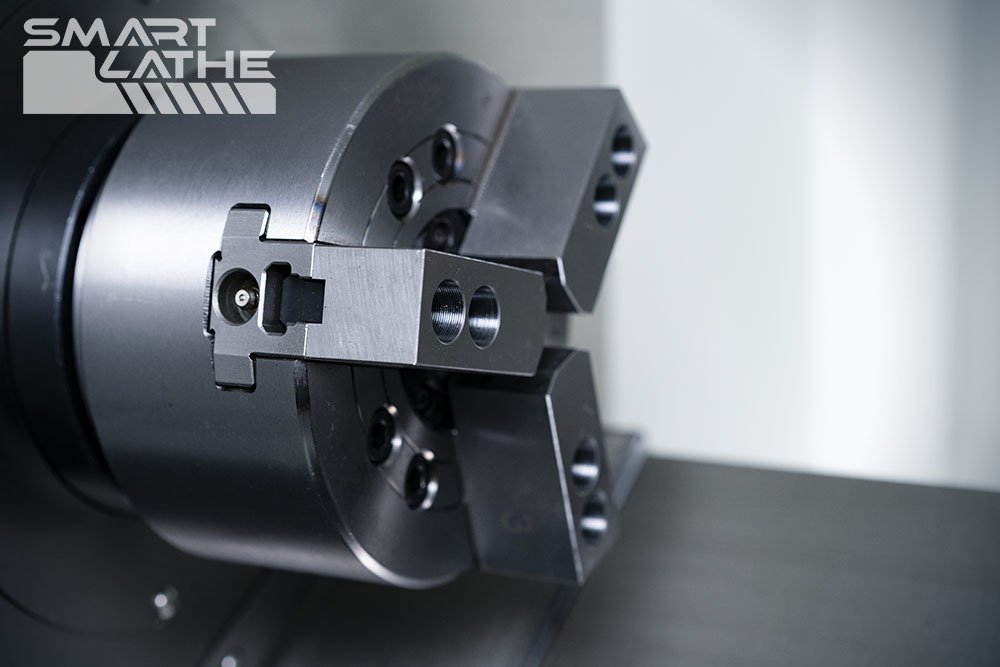

3 Jaws Chuck

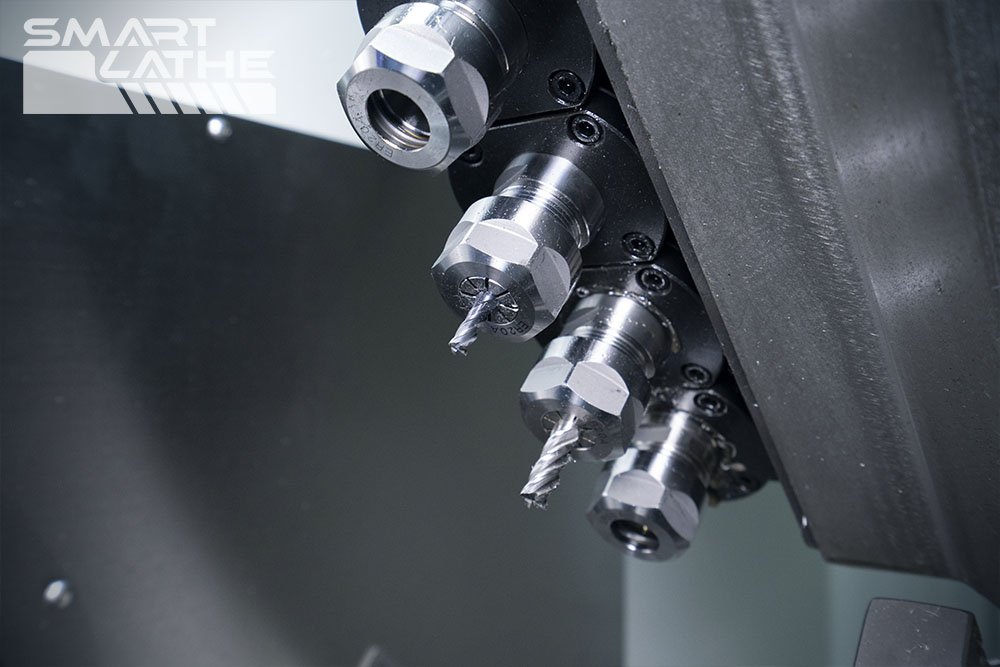

Step Type Live Tool

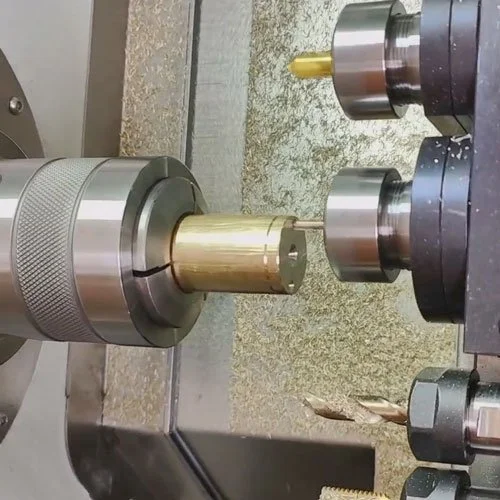

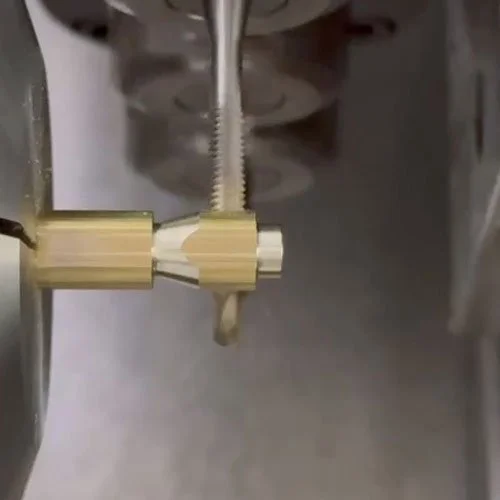

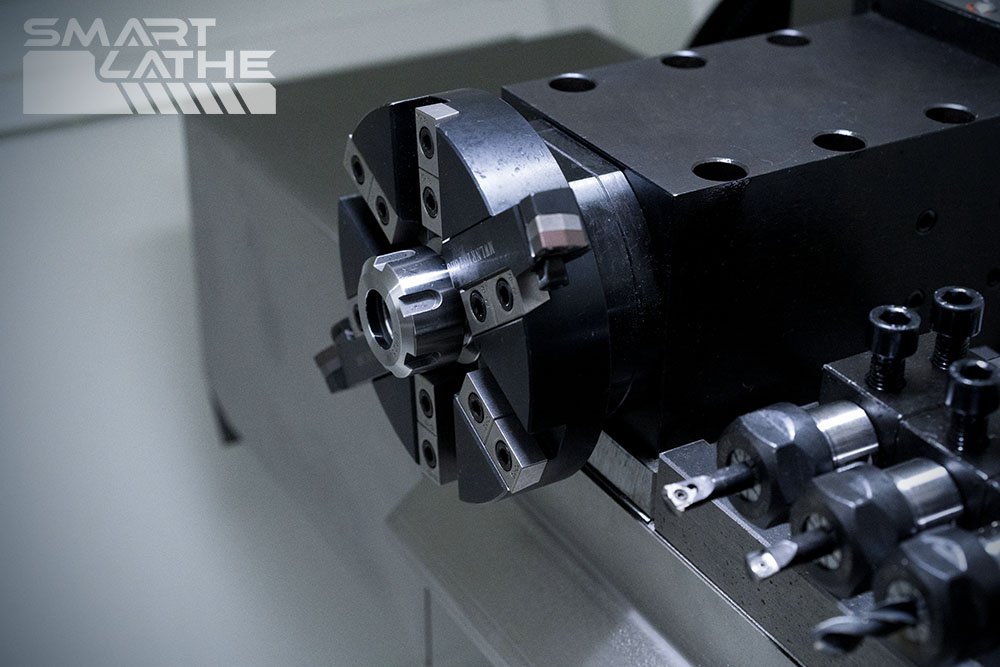

Polygon Milling

4 Shaft Live Tools |

||||||

Application

SL-36 provides both two-axis high-precision turning and the possibilities of complex multi-tasking operations like hard turning, taper turning, parting, facing, boring, grooving, reaming, drilling, threading, knurling, etc. Easily handle the bar materials with diameter max. Φ36 mm or individual workpieces diameter max. Φ350mm (Chuck size max. Φ50mm).