Smart CNC Lathe

SL-46

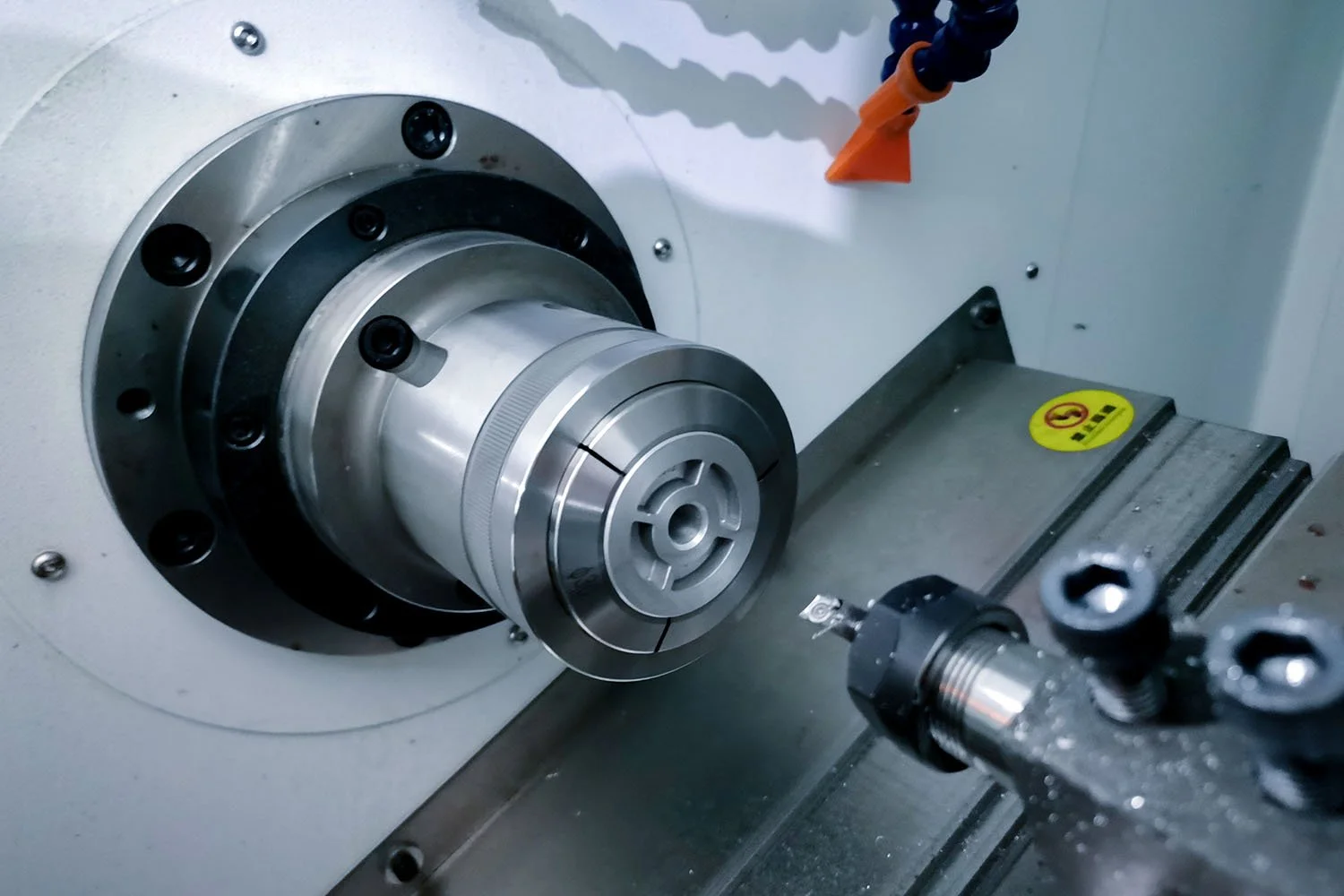

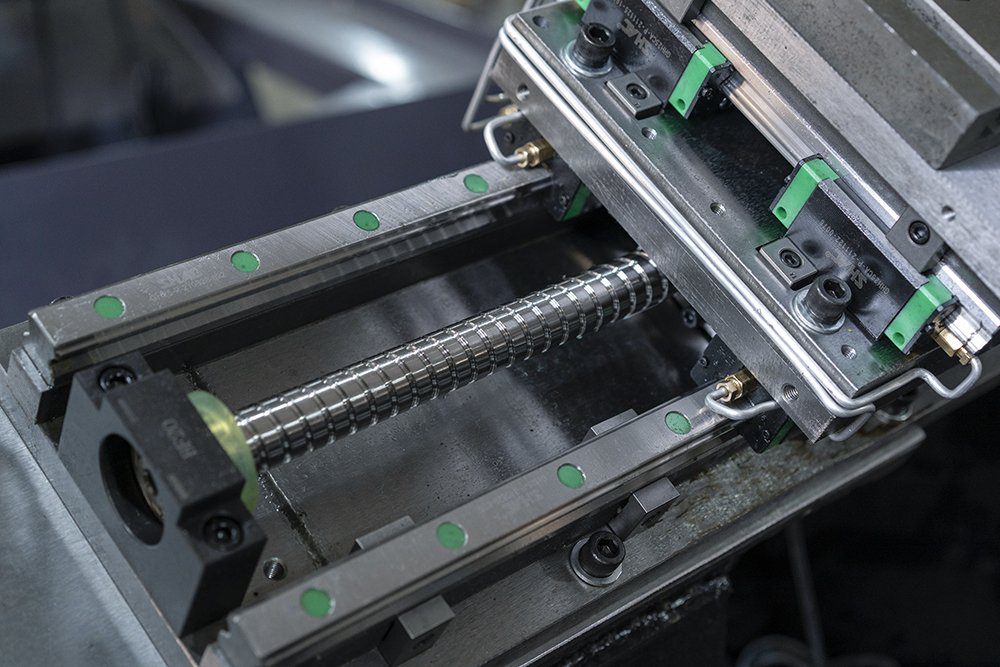

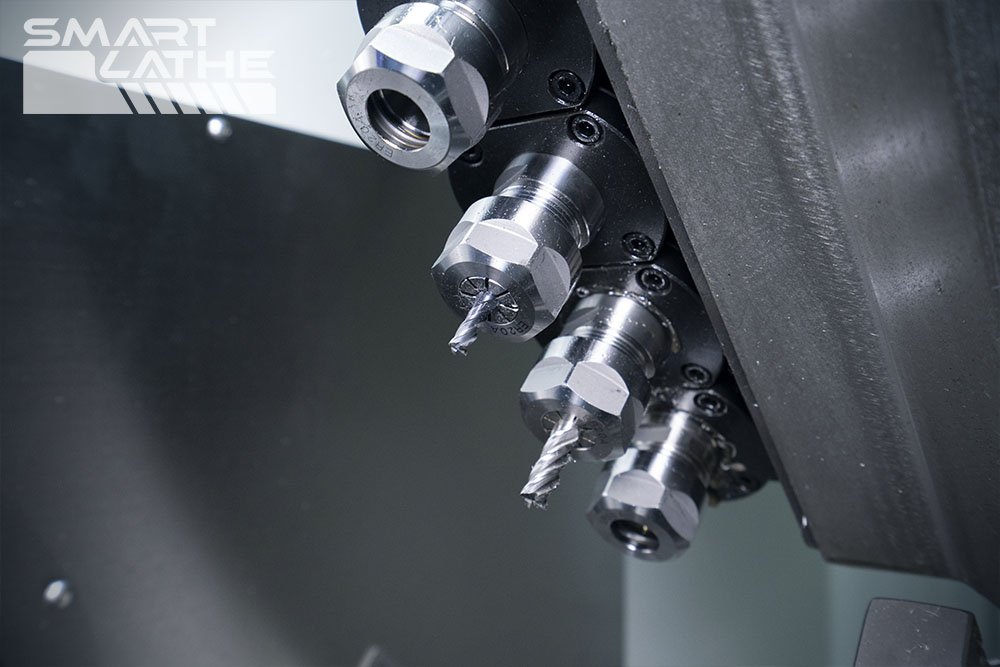

When it comes to high-throughput & high-precision machining of the complex turning parts, our SL-46 has become an industry benchmark. With a robust machine structure, highly-rigid construction, and built-in software, this machine is quite user-friendly even for entry-level machinists. An extra-large work envelope to provide roomy space for the live tooling function that provides multi-axis milling and turning and off-center line Y-axis milling capability.

| Techical Data | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Features | ||||||

|

||||||

| Optional | ||||||

Servo Bar Feeder

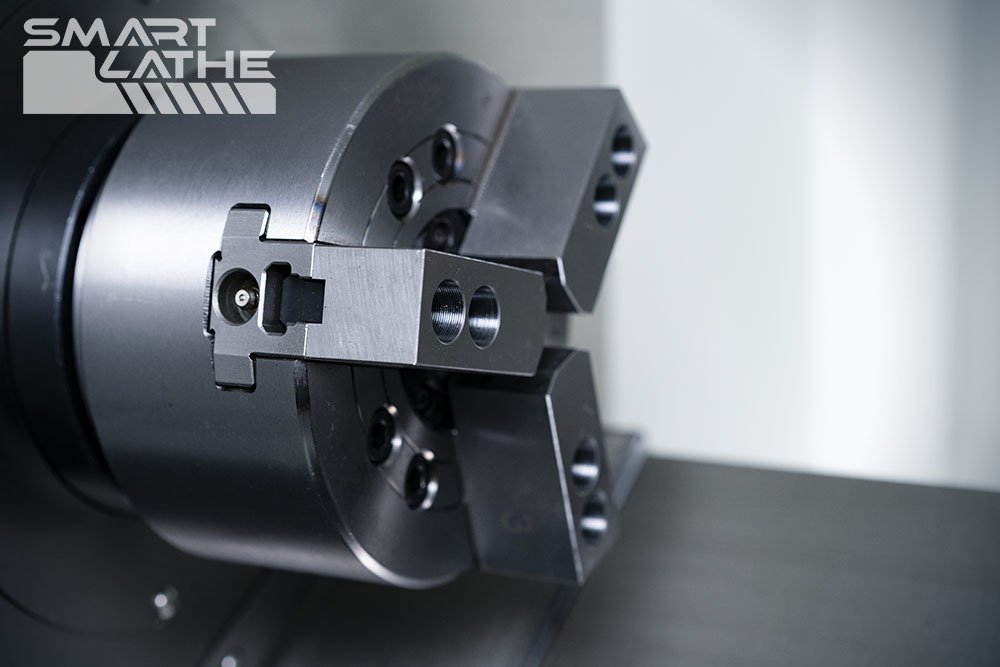

3 Jaws Chuck

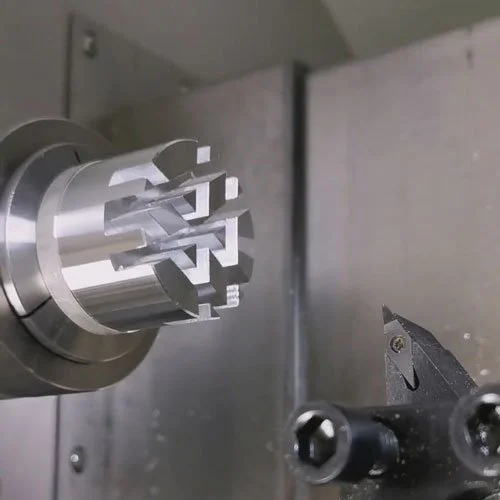

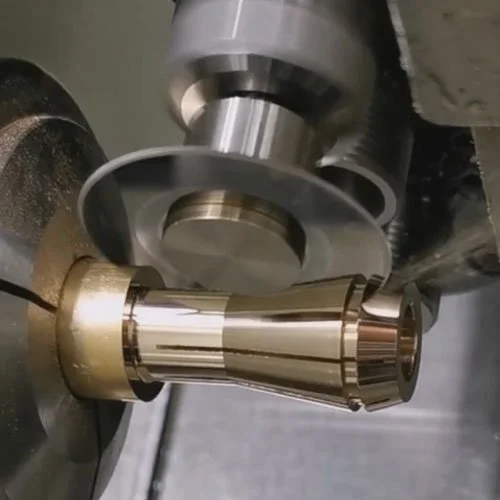

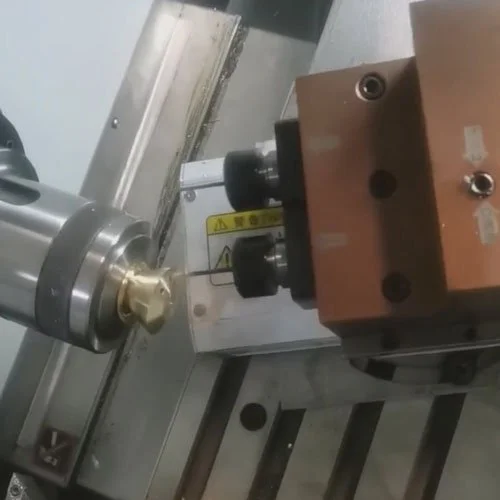

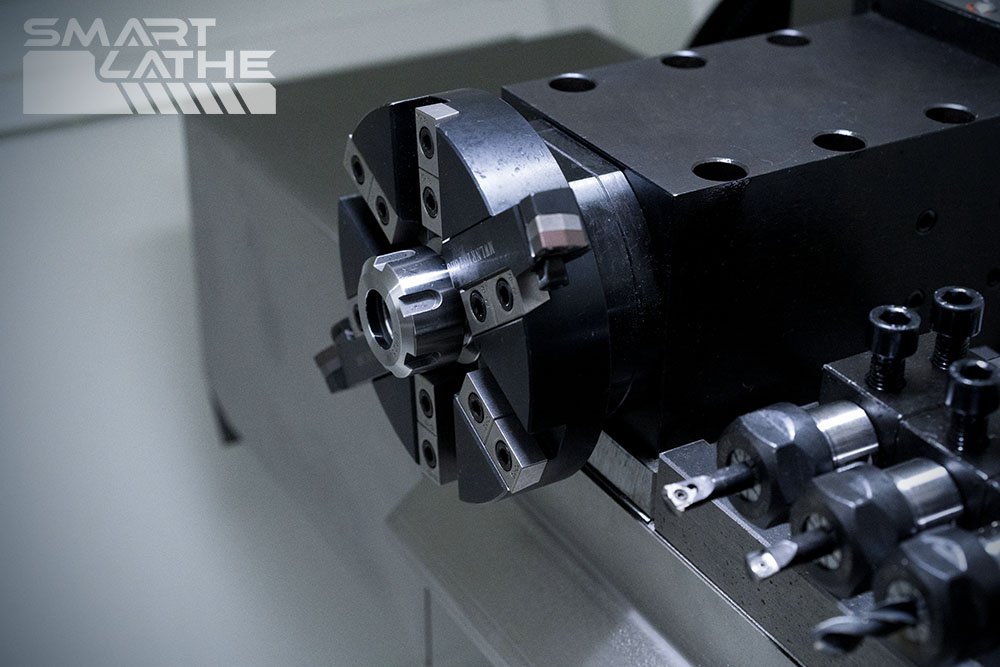

Step Type Live Tool

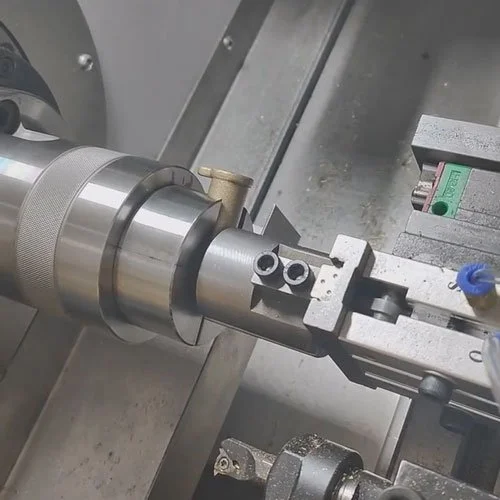

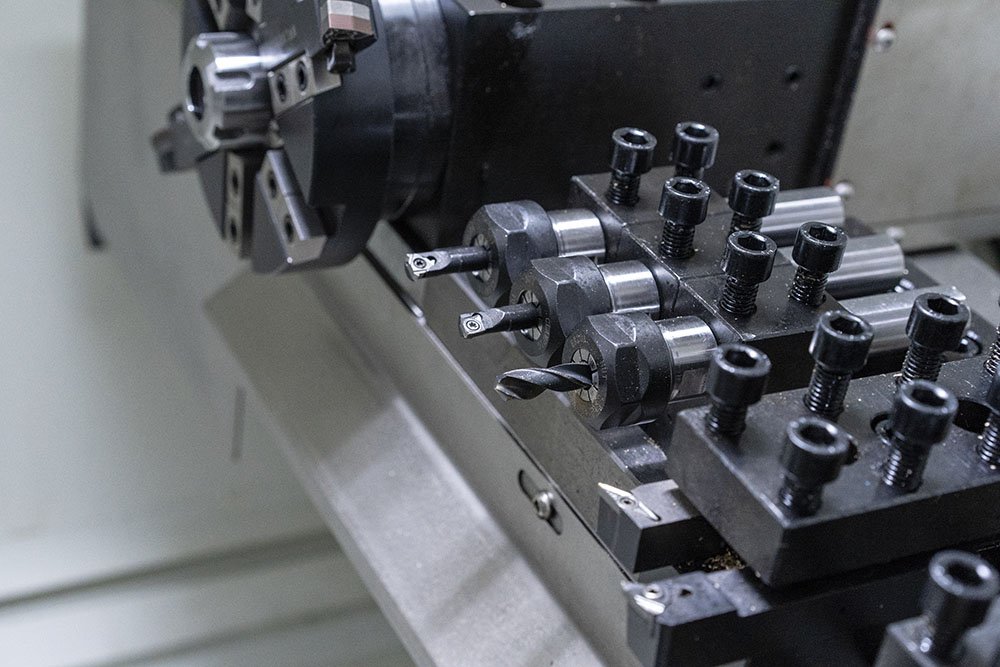

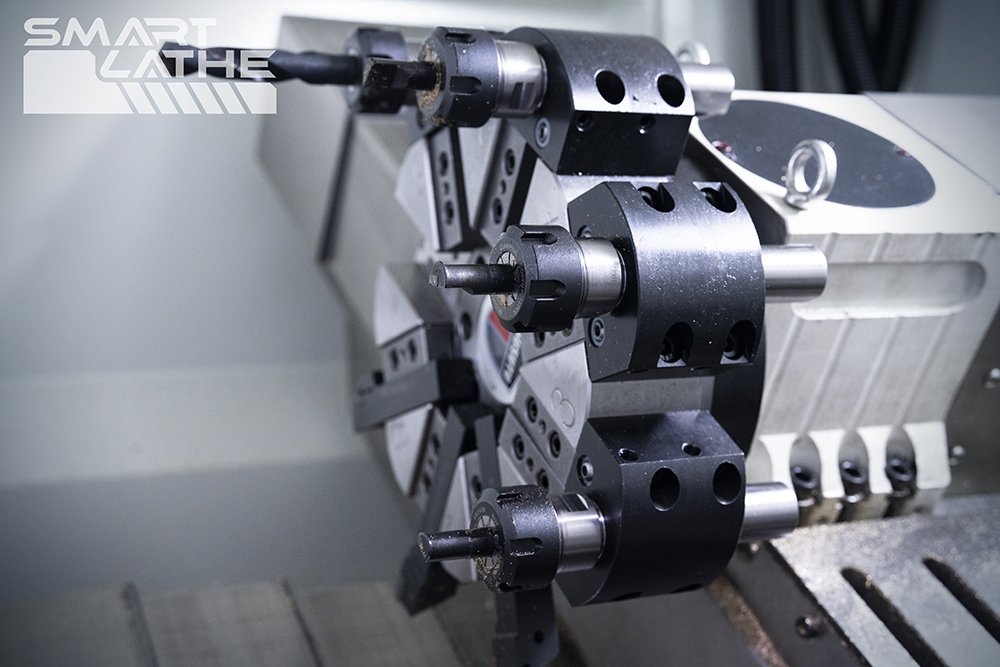

Servo Turret

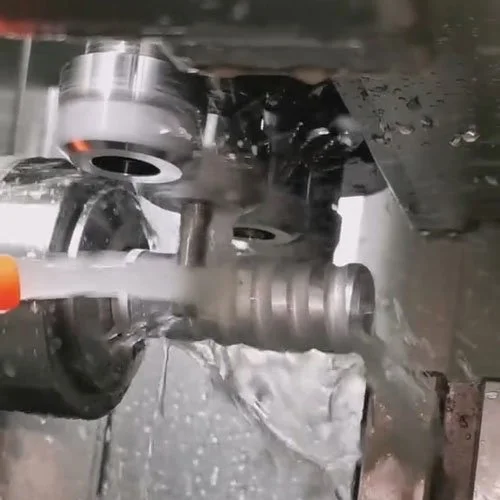

Polygon Milling

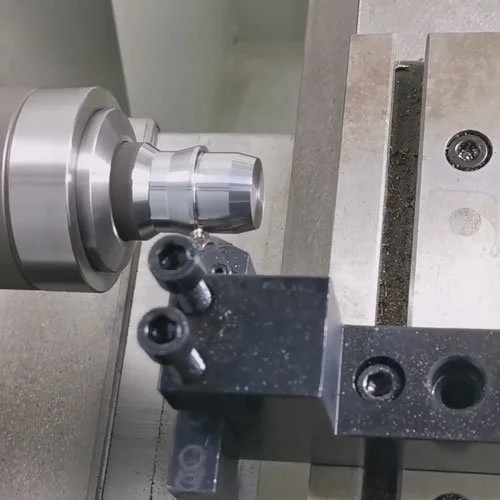

4 Shaft Live Tools |

||||||

Application

SL 46 lathe-mill CNC center delivers feature-rich with a high speed (4000 RPM) and strong power (5 HP) capable of most of the lathe working in the application of automatics, medical, aerospace, semiconductor, industrial equipment, oil & gas, etc. by holding the bar materials diameter max. Φ46 mm or single workpieces max. Φ50mm.