FRELION s.r.o.

From Feasibility Evaluation to Full-Scale Production

A Precise Start, A Fast Track to Trust – Lubomir Glogar’s CNC Journey with SmartLathe

1. From Technical Drawings to Tailored Proposals

The story of FRELION and SmartLathe began on December 25, 2022, when Mr. Lubomir Glogar reached out with machining drawings and requested an evaluation of machining strategy and cycle time. Our engineering team quickly responded, recommending the SL-X model with a servo turret and estimating a total machining time of four minutes, split across two operations.

The initial tool setup included:

2 boring tools

1 parting tool

1 U-drill

1 Thread tool

1 external turning tool

2. Engineering Support That Builds Confidence

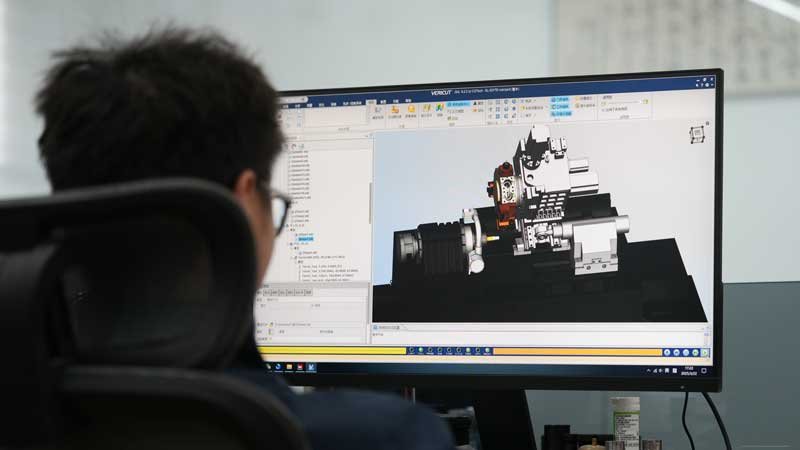

To demonstrate our proposed solution in action, we prepared a machining trial. On February 7, 2023, SmartLathe provided a full sample run, including:

Machining process videos

Finished part inspection photos

Detailed part G-code

This comprehensive preview gave FRELION clear insight into how their parts would be processed on our machines.

3. Instant Recognition and a Major Order

April 21: Final payment received, machines packed

April 26: Loading and container shipment arranged

May 27: Machines arrived at FRELION’s factory

June 10: All machines installed and fully operational

4. From Factory Floor to Customer Site

Following our installation manuals, FRELION completed setup and testing without delay. On June 10, they officially launched production using SmartLathe equipment. We later received a video showing all units running in sync, fulfilling real production tasks.

Factory producing video--20231020

5. Partnership Beyond Purchase

FRELION’s journey with SmartLathe exemplifies how professional collaboration and technical transparency lead to rapid, confident decisions. From part drawing analysis to installation, the process was smooth, fast, and efficient.

6. Key Takeaways

Pre-Sale Simulation: Live machining trials and full G-code preview helped verify feasibility.

Fast Decision: Confirmed multi-machine purchase just one day after receiving trial results.

Efficient Fulfillment: From order to production launch in less than 6 months.

Reliable Operation: Machines delivered, installed, and producing with zero post-installation issues.

SmartLathe is proud to support FRELION in their mission for quality machining. We look forward to powering their growth with reliable, high-performance CNC solutions.

For more product information about the high quality Hydraulic hose, please contact FRELION ——>