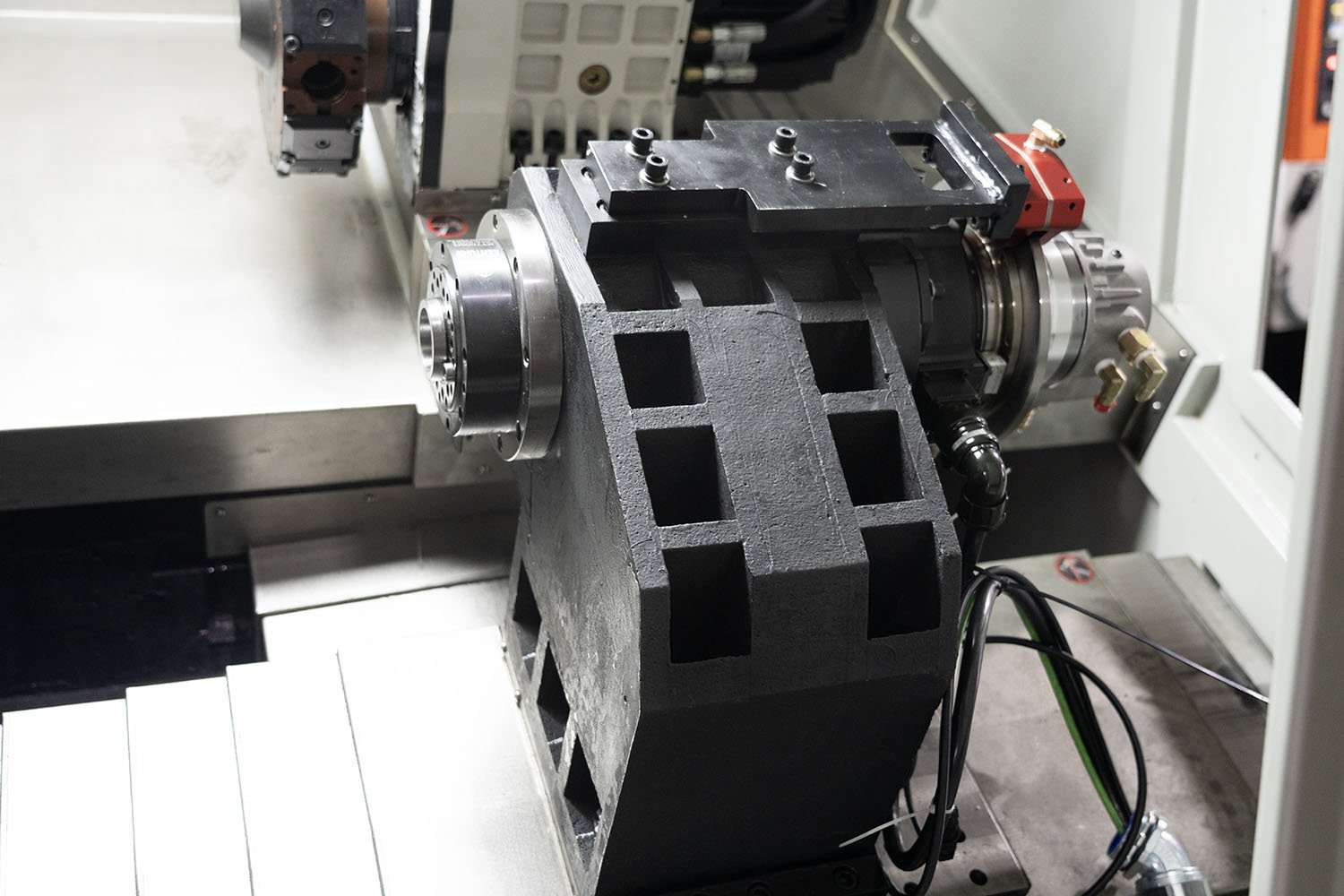

Dual Spindle CNC Lathe

DS-4636DTY

DS-4636DTY Dual-spindle Dual-turret The CNC Lathe Machine is the ideal solution for operations ranging from large, diverse industrial and automotive markets to the general job shop looking to upgrade from a single spindle/turret machine.

| Techical Data | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Features | ||||||||||

|

||||||||||

| Optional | |||||||||||

|

|||||||||||

Application

DS-4636DTY is a professional and high-end model with a dual spindle, dual turret, and dual Y-axis horizontal turning centers specialized in the multi-task process for precision complex parts in one setup, which could compete to handle the turning process of double-ended parts in a single setup with brass, bronze, aluminum, steel, stainless steel, and rigid plastic with bar material up to Φ46mm or single workpieces up to Φ200mm. This model allows you to increase maximum productivity by streamlining the process.

Case Study

Configuration: DS-4636DTY installs the 3-Jaw Hydraulic Chuck, Power turret, High pressure coolant.

Workpiece: Sleeve

Machining Process: Turning, Facing, Drilling, Milling, Threading.

Turning Duration: within 90 seconds of one-time processing